Method and equipment for leaching platinum-containing waste catalyst through mechanical activation

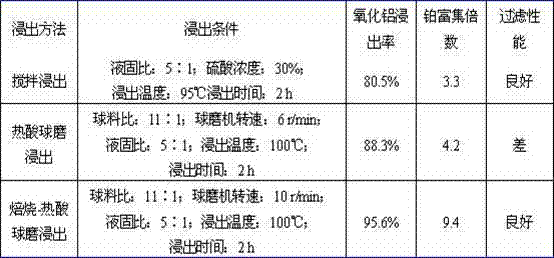

A mechanical activation, platinum catalyst technology, applied in the field of hydrometallurgy, can solve the problem of difficult separation of platinum and matrix, and achieve the effect of improving leaching thermodynamics and kinetic conditions, reducing equipment requirements, and reducing acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

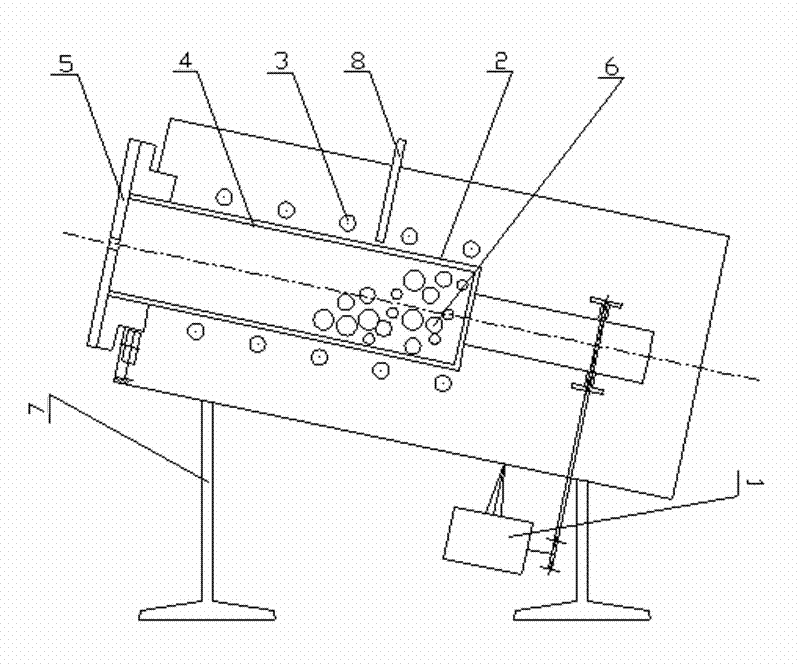

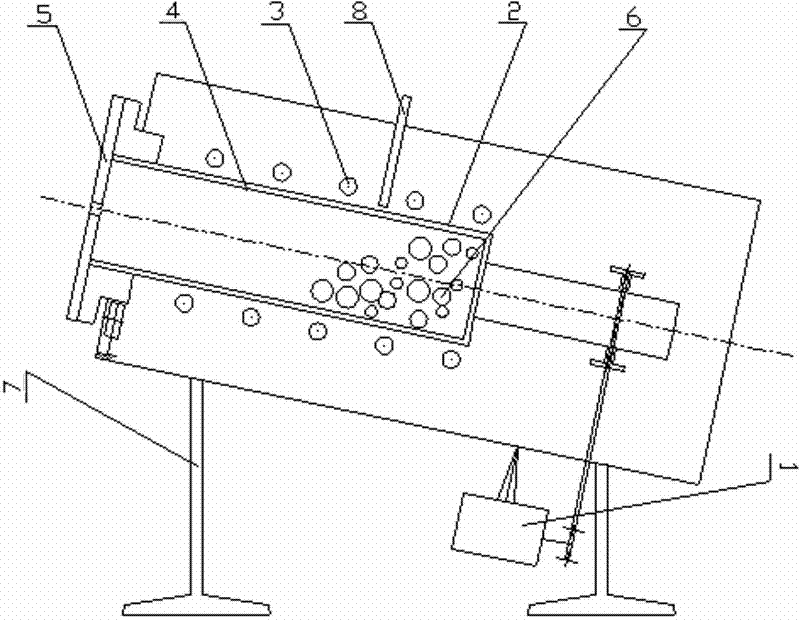

Image

Examples

Embodiment 1

[0032] A certain spherical (particle size 1-2 mm) platinum-containing spent catalyst, containing 0.19% platinum. Firstly, it is fired at 550°C for 2 hours in an air atmosphere with a natural particle size. Weigh 100 g of the platinum-containing waste catalyst pretreated by roasting, put it in the activation leaching equipment with 500 mL of sulfuric acid (50% mass concentration), and add zirconia balls with a ratio of Φ10:Φ6:Φ4 =3:4:4 1300g, the filling rate is 40%, set the speed at 6 r / min, start heating, leaching at 100°C for 4 h and then filtering. After the slag is dried, platinum is recovered from the filter residue, and aluminum sulfate is recovered from the filtrate. After testing, the platinum content is 1.91%, enriched by 10.05 times, and the leaching rate of alumina is 95.60%.

Embodiment 2

[0034]A certain spherical (particle size 1-2 mm) platinum-containing spent catalyst, containing 0.19% platinum. Firstly, it is calcined at 600°C for 1 hour under air atmosphere and natural particle size. Weigh 100 g of the platinum-containing waste catalyst pretreated by roasting, put it in the activation leaching equipment with 500 mL of sulfuric acid (50% mass concentration), and add zirconia balls with a ratio of Φ10:Φ6:Φ4 =3:4:4 1300g, the filling rate is 50%, the speed is set at 6 r / min, heating is started, leaching at 100°C for 4 h and then filtering. After the slag is dried, platinum is recovered from the filter residue, and aluminum sulfate is recovered from the filtrate. After testing, the platinum content is 2.08%, enriched by 10.95 times, and the leaching rate of alumina is 96.09%.

Embodiment 3

[0036] A certain spherical (particle size 1-2 mm) platinum-containing spent catalyst, containing 0.19% platinum. Firstly, it is calcined at 580°C for 1 hour under air atmosphere and natural particle size. Weigh 100 g of the platinum-containing spent catalyst pretreated by roasting, place it in the activation leaching equipment with 800 mL of sulfuric acid (mass concentration: 40%), and add 1100 zirconia balls with a ratio of Φ10:Φ6:Φ4 =3:4:4. grams, the filling rate is 40%, set the rotation speed at 8 r / min, start heating, leaching at 100°C for 2 hours and then filtering. After the slag is dried, platinum is recovered from the filter residue, and aluminum sulfate is recovered from the filtrate. After testing, the platinum content is 2.02%, enriched by 10.63 times, and the leaching rate of alumina is 94.09%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com