Interlayer alloy of DD6 nickel-based single crystal high temperature alloy used for transient liquid phase (TLP) bonding and preparation method thereof

A nickel-based single crystal, high-temperature alloy technology, applied in the field of welding materials, can solve problems such as weld thermal cracks and low strength of brazed joints, and achieve the effects of easy processing and assembly, low production cost, and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the aforementioned intermediate layer alloy of the present invention is implemented according to the following steps,

[0015] Step A, using an ultra-high vacuum electric arc furnace to melt the master alloy:

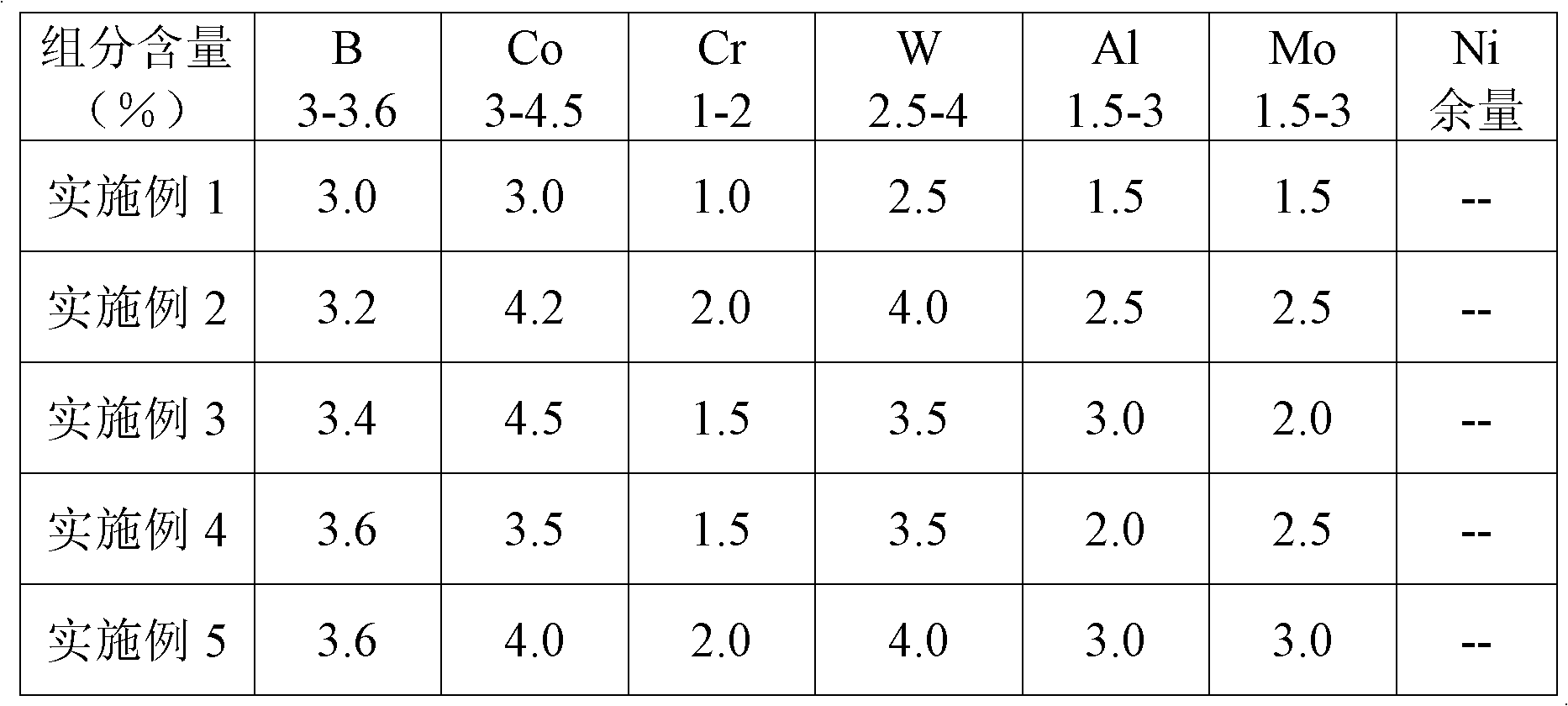

[0016] A1. Weigh the following high-purity metals according to atomic percentage: the total percentage is 100%, of which: B is 3%-3.6%, Co is 3%-4.5%, Cr is 1%-2%, and W is 2.5% %-4%, Al is 1.5%-3%, Mo is 1.5%-3%, and the balance is Ni. The purity of all high-purity metals is higher than 99.99%; High-purity metals are purified separately;

[0017] A2. Divide the Ni purified and treated in step A1 into three parts, each part of Ni and other high-purity metals are melted and matched according to the combination of Ni-Co-Cr, Ni-Al, and Ni-B-W, and three groups of middle parts are obtained. transition alloys;

[0018] A3, the three groups of intermediate transition alloys obtained in step A2 are put together for secondary fusion to obtain...

Embodiment 1

[0025] Weigh each component element content according to the data of embodiment 1 in table 1, and implement according to the following steps:

[0026] Step A, using an ultra-high vacuum electric arc furnace to melt the master alloy:

[0027] A1, each high-purity metal weighed is carried out purifying treatment respectively with boric anhydride;

[0028] A2. Divide the Ni purified and treated in step A1 into three parts, each part of Ni and other high-purity metals are melted and matched according to the combination of Ni-Co-Cr, Ni-Al, and Ni-B-W, and three groups of middle parts are obtained. transition alloys;

[0029] A3, the three groups of intermediate transition alloys obtained in step A2 are put together for secondary fusion to obtain the intermediate master alloy;

[0030] Step B, using a single-roll rapid solidification device, controlling the linear speed of the roller at 5m / s, preparing the intermediate master alloy obtained in step A3 into a foil, the thickness of...

Embodiment 2

[0032] Example 2: According to the steps of Example 1 above, the elements and contents of each component were weighed according to the data in Example 2 in Table 1, and the prepared product had a thickness of 30-80 μm, a width of 5-8 mm, and a length of 1-2 m. The intermediate layer alloy foil prepared in Example 2 was applied to the TLP method to weld the DD6 nickel-based single crystal superalloy sample. The welding process parameters were: welding temperature 1200°C, holding time 8h, welding pressure 0.3MPa, Vacuum degree 5×10 -2 Pa. The heating specification is: heating to 1000°C at a heating rate of 10°C / min, holding for 30 minutes; welding temperature of 1200°C, holding for 8 hours, and cooling to room temperature with the furnace. The microstructure of the obtained welded joint has a good match with the base metal, and the weld is a single crystal microstructure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com