Plane opening and closing structure of high-pressure common rail oil injector of diesel engine

A high-pressure common rail and open-close structure technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem that the machining accuracy of the throttling taper hole cannot reach the design accuracy, the operator's technical level is difficult to adapt, and the yield rate is not high, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

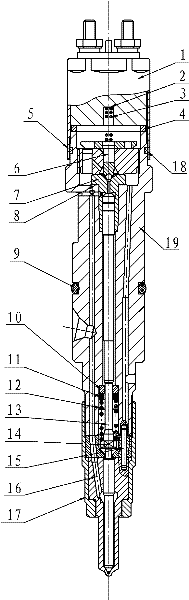

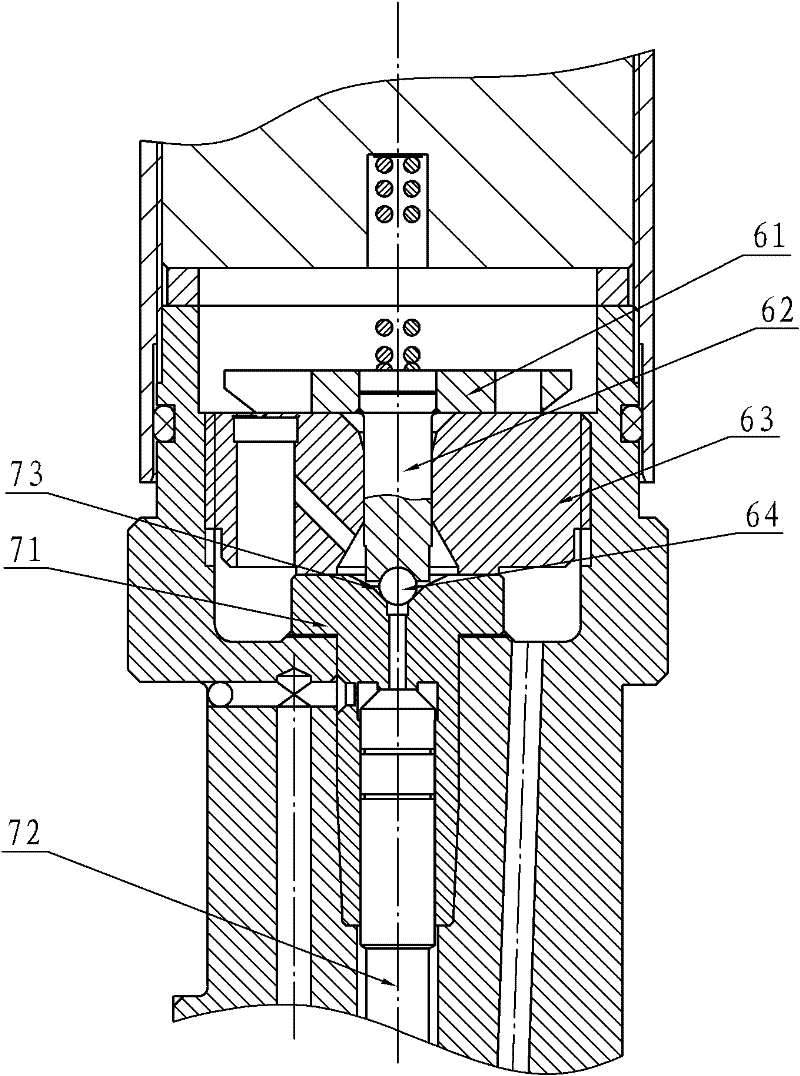

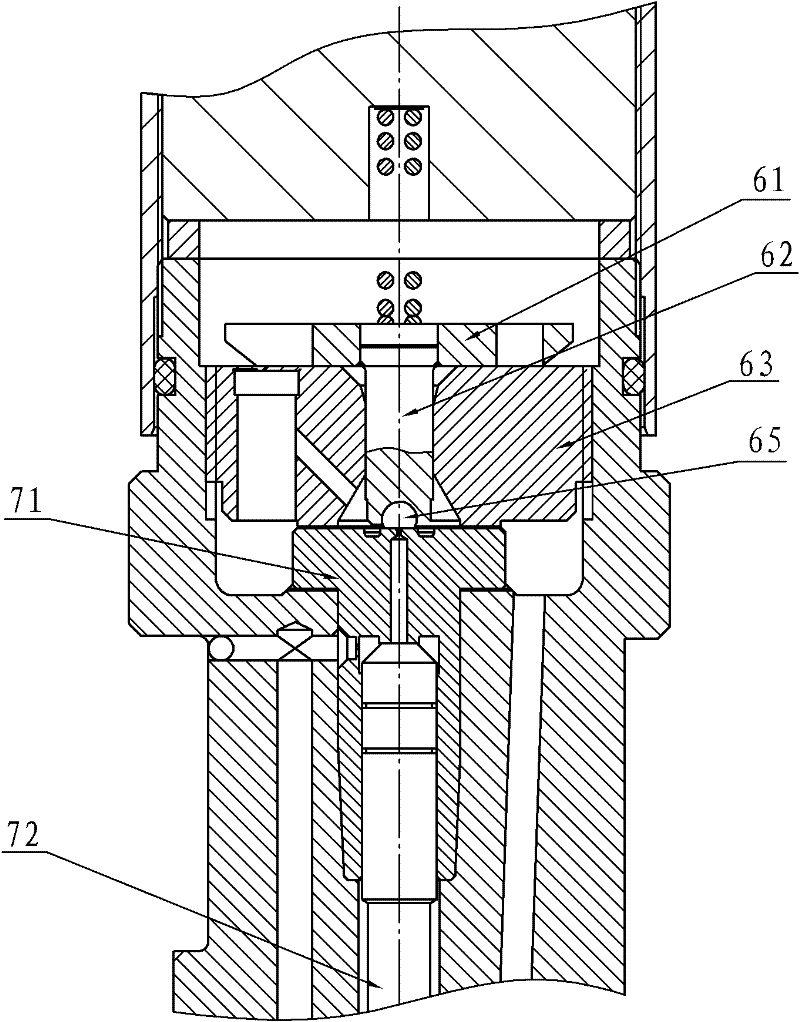

[0023] Figure 4 It is equipped with the high-pressure common rail fuel injector for diesel engine of the present invention, which includes solenoid valve 1, solenoid valve spring adjustment washer 2, solenoid valve spring 3, lining ring 4, electromagnet tight cap 5, control valve coupler 6, valve assembly 7. Orifice plate positioning pin 8, sealing ring 9, spring upper seat 10, adjusting gasket 11, pressure regulating spring 12, ejector rod 13, transition block 14, oil nozzle positioning pin 15, fuel injection nozzle coupler 16, fuel injection nozzle tight cap 17. The upper sealing ring 18 and the fuel injection nozzle coupling body 19, wherein the control valve coupling 6 is as image 3 with Figure 5 As shown, it consists of a magnet 61, a movable valve core 62, a fixed valve seat 63 and a plane sealing ball 65. The movable valve core 62 is fixedly installed in the center of the magnet magnet 61. The material of the plane seal ball 65 is ceramics, and the plane seal ball 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com