Method for utilizing oxygen-nitrogen liquefaction device to prepare high-purity oxygen

A liquefaction device, high-purity oxygen technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of limited production and refrigeration capacity, large investment, etc., and achieve the effect of lowering the production threshold, efficient process, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

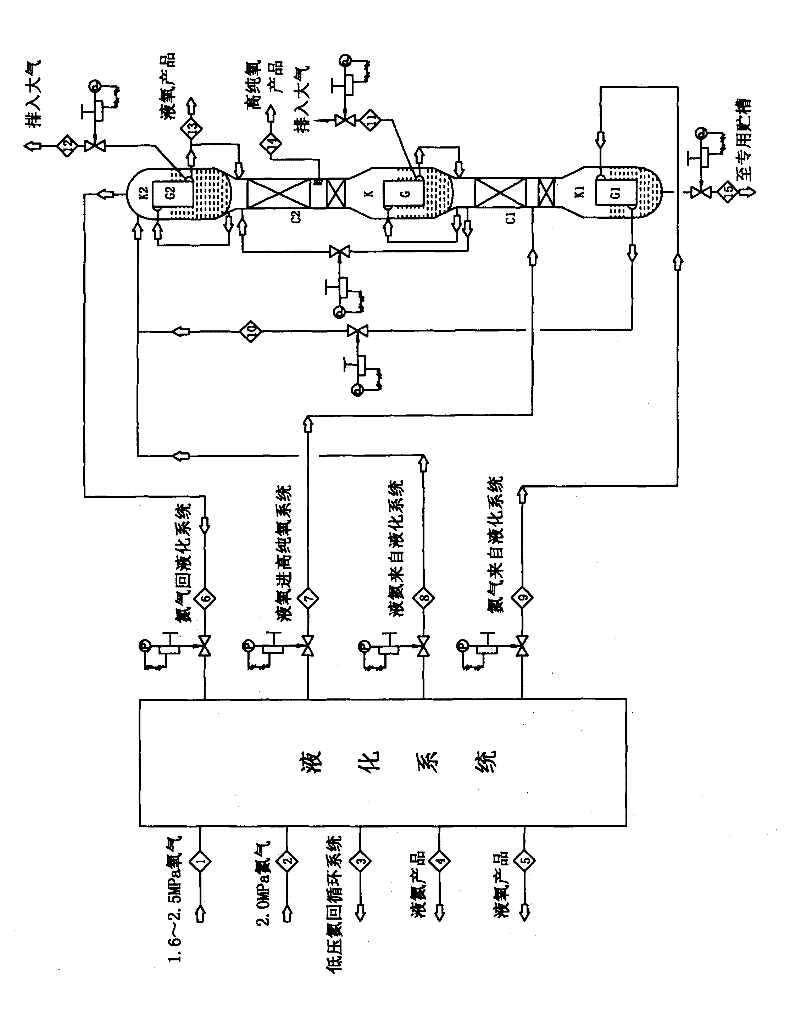

[0036] A method for producing high-purity oxygen by using an oxygen-nitrogen liquefaction device is carried out in the following manner:

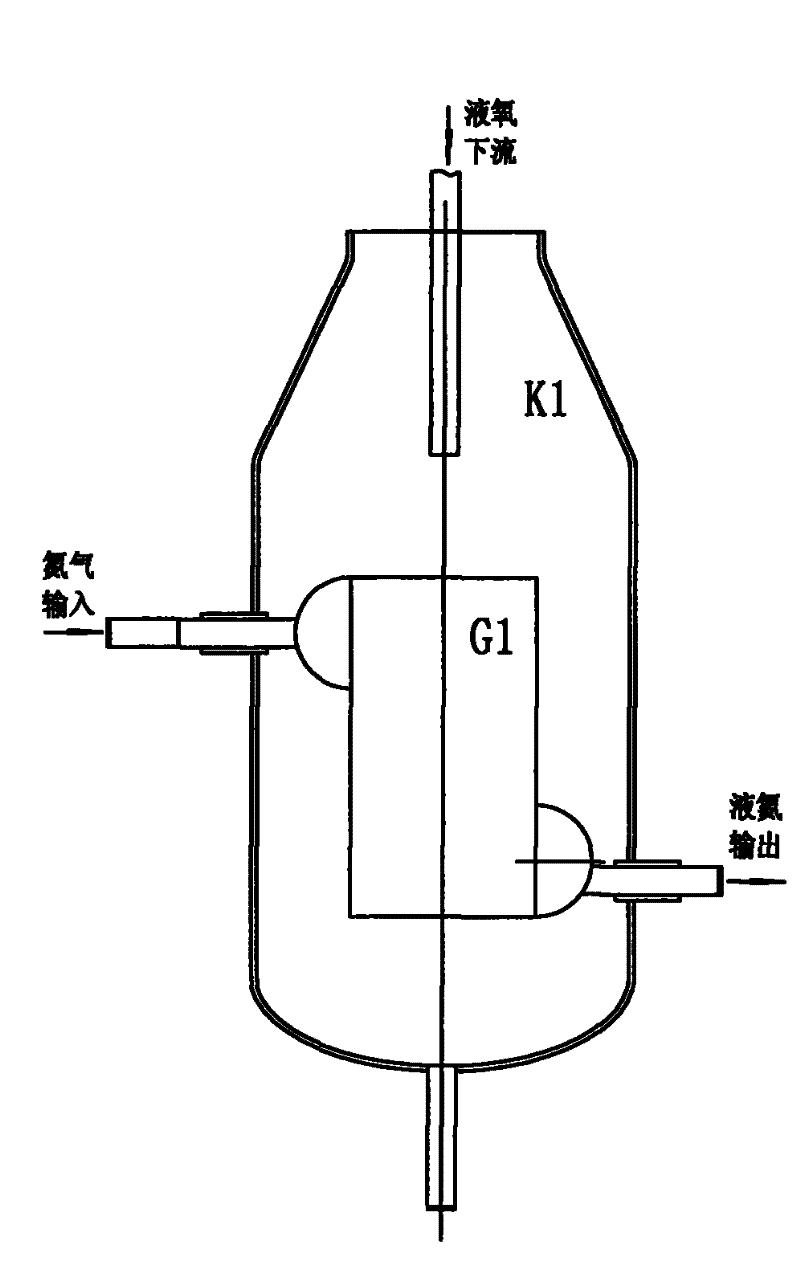

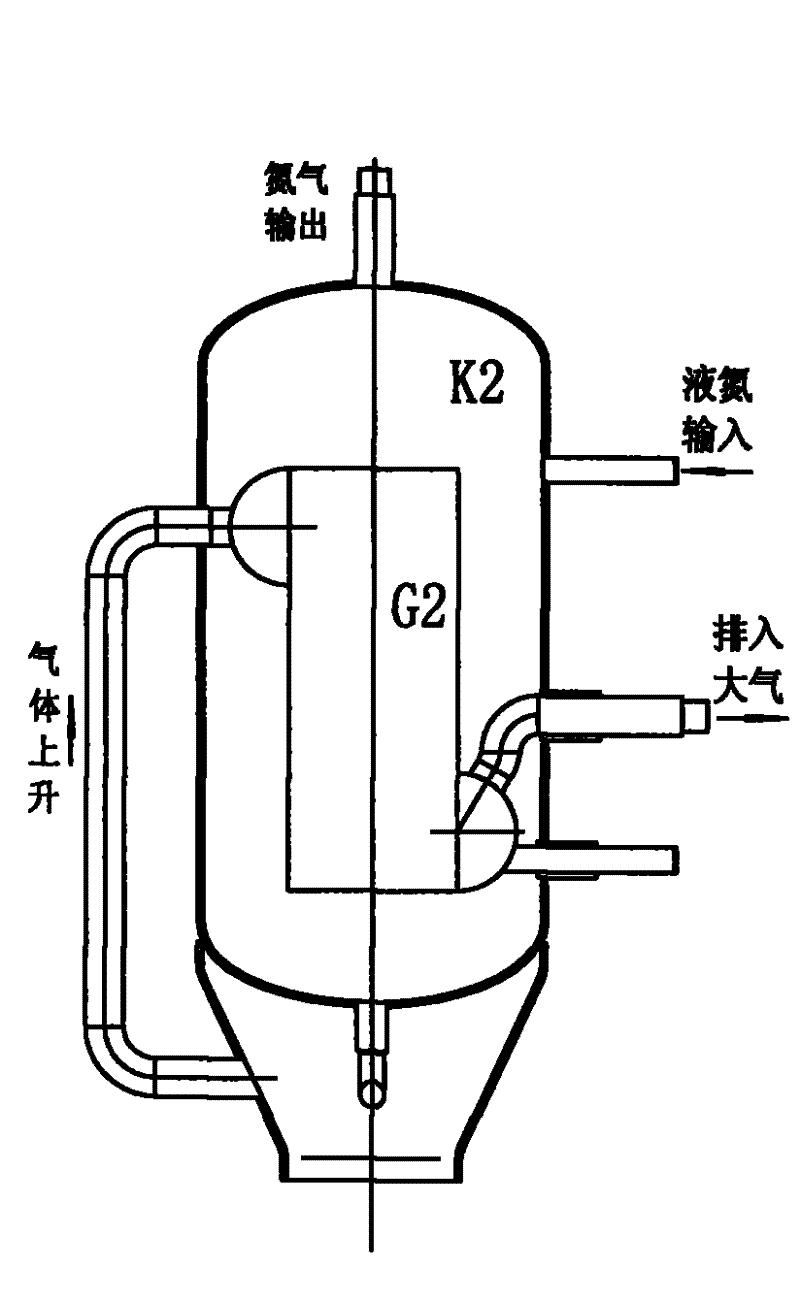

[0037] a. The first rectification tower evaporator K1, the first rectification tower C1, the main condensation evaporator K, the second rectification tower C2, and the second rectification tower condenser K2 are fixedly arranged in order from bottom to top, and the first rectification tower A rectification tower evaporator K1 is communicated with the first rectification tower C1, and the main condensing evaporator K is communicated with the second rectification tower C2; and then the follow-up operation process is carried out simultaneously;

[0038] b. The nitrogen output from the oxygen and nitrogen liquefaction device YD is passed into the absorption chamber G1 of the evaporator K1 of the first rectification tower to absorb the cooling capacity, converted into liquid nitrogen, and then flows out of the first rectification tower, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com