Method for detecting total amount of perfluorooctane sulphonates (PFOS) in textile and leather

A perfluorooctanesulfonyl and detection method technology, applied in the field of detection and analysis, to achieve high extraction efficiency, realize analysis and detection, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

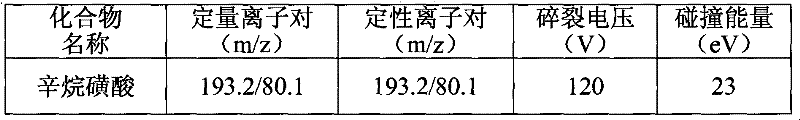

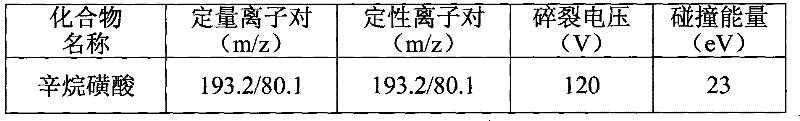

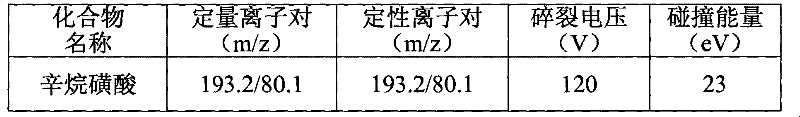

Image

Examples

Embodiment 1

[0027] Example 1: Determination of the total amount of perfluorooctanesulfonyl substances in leather

[0028] (1) Solvent extraction

[0029] Accurately weigh about 1g of sample particles that are cut into pieces (about 4mm×4mm), add them to a 100ml conical flask with a stopper, add 30mL of methanol, and extract in an ultrasonic bath (40Hz) for 30min after stoppering; filter out the extract, and use 60mL of methanol was extracted twice, each time for 10min; the extracts were combined, and about 2g of anhydrous magnesium sulfate was added for dehydration, and then the volume was adjusted to 100.0mL.

[0030] (2) Chemical treatment of extract

[0031] Pipette 10.0 mL of the sample solution into a 150 mL flat-bottomed flask, concentrate to dryness by rotation, add 5 mL of chromatographic grade tetrahydrofuran, and concentrate by rotation to dryness again; then add 5 mL of a solution containing a cleavage reagent to the bottle, and reflux at 90°C for 60 minutes; Remove the flask...

Embodiment 2

[0042] Example 2: Determination of the total amount of perfluorooctanesulfonyl substances in textiles

[0043] (1) Solvent extraction

[0044] Accurately weigh about 1g of sample particles that are cut into pieces (about 4mm×4mm), add them to a 100ml conical flask with a stopper, add 30mL of methanol, and extract in an ultrasonic bath (40Hz) for 30min after stoppering; filter out the extract, and use 60mL of methanol was extracted twice, each time for 10min; the extracts were combined, and about 2g of anhydrous magnesium sulfate was added for dehydration, and then the volume was adjusted to 100.0mL.

[0045] (2) Chemical treatment of extract

[0046] Pipette 10.0 mL of the sample solution into a 150 mL flat-bottomed flask, concentrate to dryness by rotation, add 5 mL of chromatographic grade tetrahydrofuran, and concentrate by rotation to dryness again; then add 5 mL of a solution containing a cleavage reagent to the bottle, and reflux at 90°C for 60 minutes; Remove the flask,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com