Method for manufacturing solar battery

A manufacturing method and technology of solar cells, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of low open circuit voltage, unfavorable mass production, low energy gap, etc., and achieve optimal component characteristics and high open circuit voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

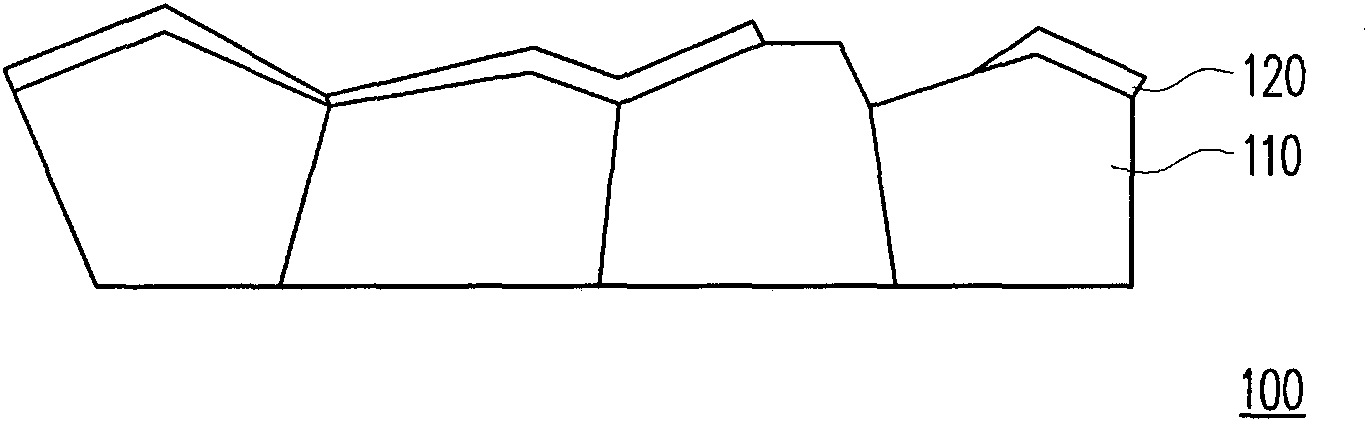

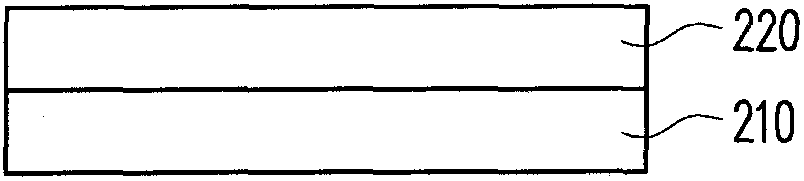

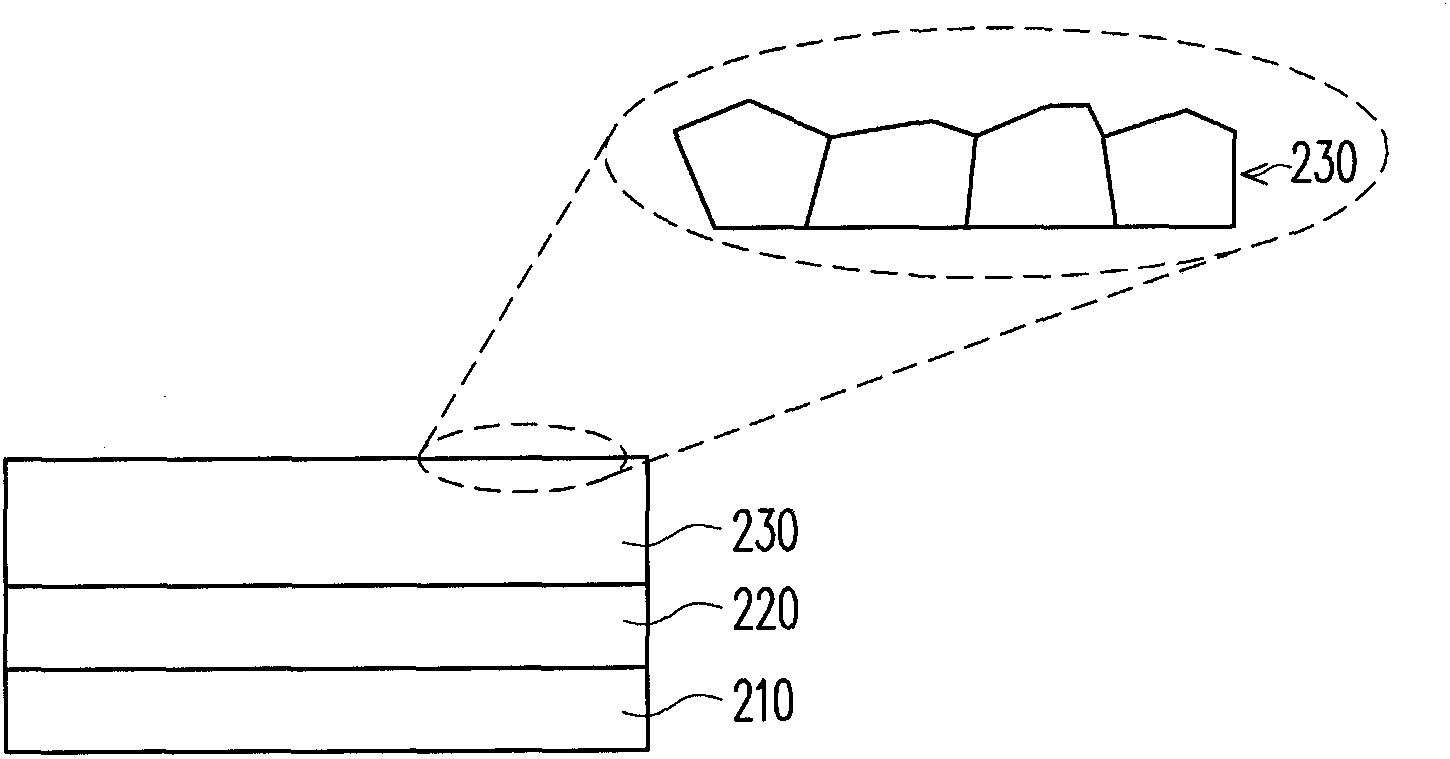

[0032] Figure 2A to Figure 2F It is a schematic flowchart of a method for manufacturing a solar cell in an embodiment of the present invention.

[0033] Please refer to Figure 2A Firstly, a substrate 210 is provided, and a base electrode 220 is formed on the substrate 210 . In this embodiment, the substrate 210 is, for example, glass, metal substrate (such as stainless steel plate), polymer film (such as plastic) or other suitable materials, which is not limited in the present invention, and the material of the base electrode 220 includes molybdenum, Metal conductors such as titanium, tungsten or aluminum are used as the back electrode of the solar cell to facilitate hole conduction.

[0034] Next, please refer to Figure 2B , forming a CIGS crystal layer 230 on the base electrode 220 as a light absorbing layer. The way to form the CIGS crystalline layer 230 can be vacuum coating techniques such as co-evaporation (Co-evaporation), selenization (Selenization) or sputterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com