Pure hardware simulation controller for DC brushless motor

A brushless DC motor and controller technology, applied in the direction of single motor speed/torque control, electronic commutator, sustainable manufacturing/processing, etc., can solve the problems of increased cost and waste, and achieve convenient speed regulation and improved Efficiency, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below by specific embodiment and in conjunction with accompanying drawing, the present invention is described in further detail:

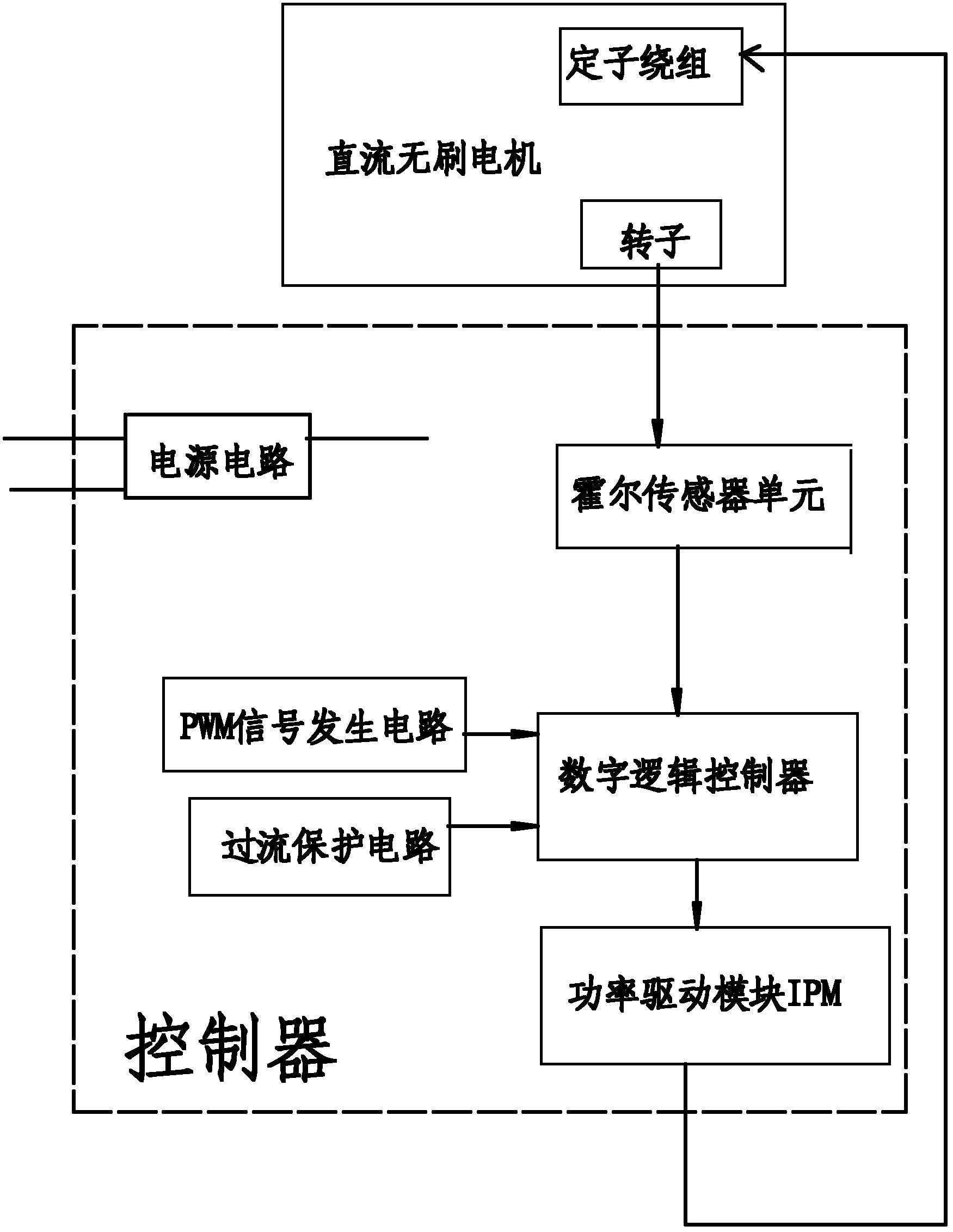

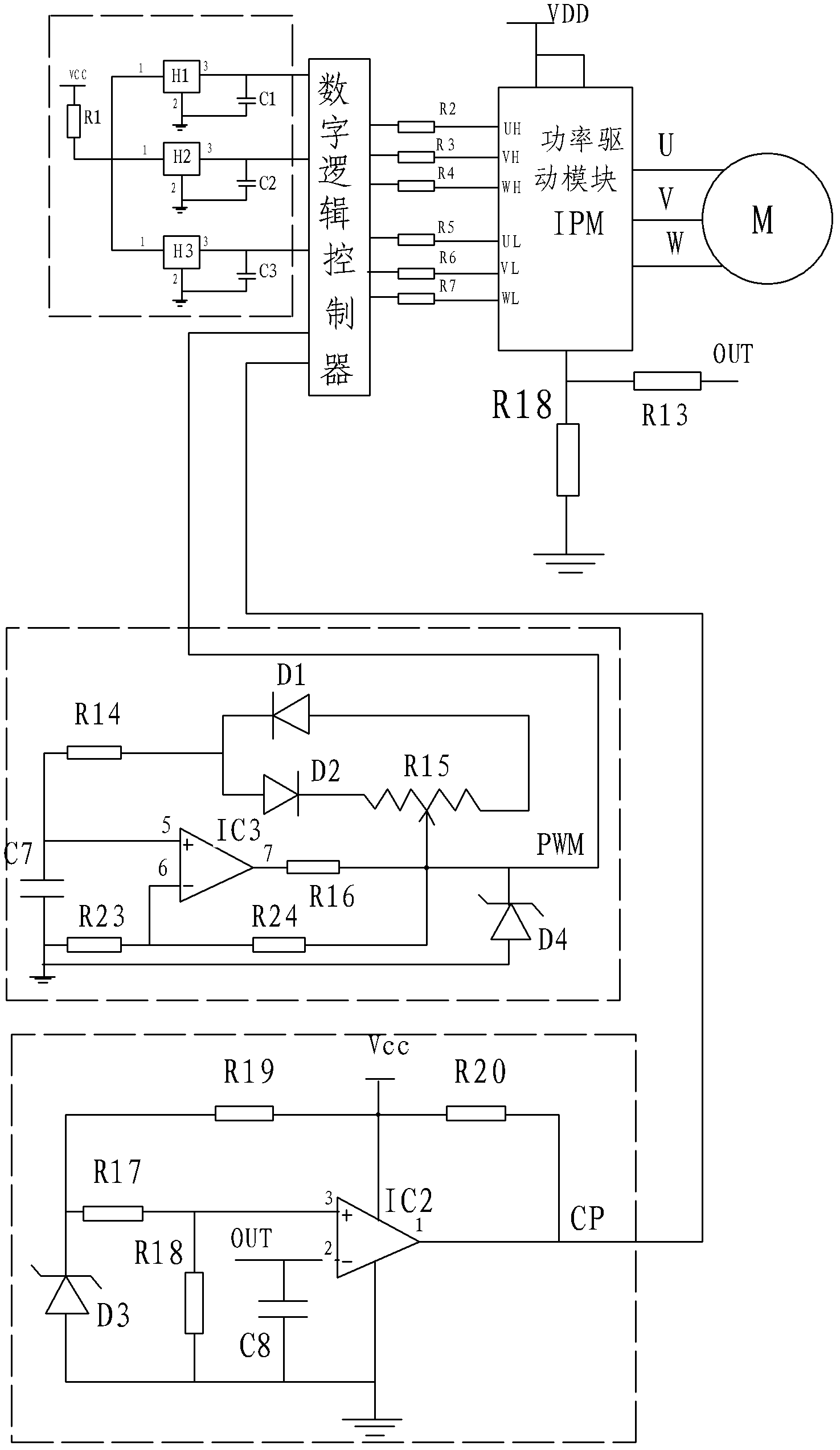

[0024] like figure 1 , figure 2 As shown, a pure hardware analog controller of brushless DC motor, including Hall sensor and decoding unit, digital logic controller and power drive module IPM, Hall sensor unit detects the position signal of the rotor and sends the signal to the digital Logic controller processing, it is characterized in that: it also comprises PWM signal generation circuit, the PWM signal output of PWM signal generation circuit is input to digital logic controller processing, and the output end of digital logic controller is connected the input end of power drive module IPM, and power The output end of the drive module IPM is connected to the stator winding, the carrier frequency and duty cycle of the PWM signal output by the PWM signal generating circuit are adjustable, and the input end of the digital logic controller is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com