A high-throughput micro-droplet immobilization method and its special microfluidic chip

A microfluidic chip and immobilization method technology, which is applied in the direction of chemical instruments and methods, laboratory containers, instruments, etc., can solve the problems of complex chip design requirements, harsh chip requirements, and easy residual liquid droplets, etc., to achieve easy and flexible Combination and scale integration, simple manufacturing, fixed effect stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

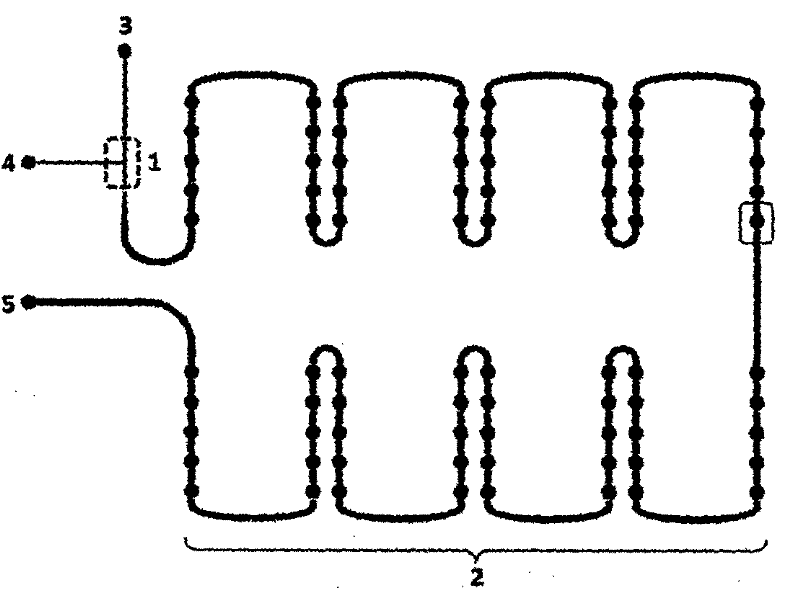

[0029] A high-throughput microdroplet immobilization method on a microfluidic chip based on the principles of buoyancy and surface tension and a dedicated chip. The specific process of the method is:

[0030] The continuous phase and dispersed phase inlets on the chip are respectively connected to two syringe pumps through Teflon tubes. Driven by the syringe pump, the continuous phase and the dispersed phase are injected into the chip respectively, and then the T-shaped droplets are formed in the generation area. Continuous monodisperse droplets;

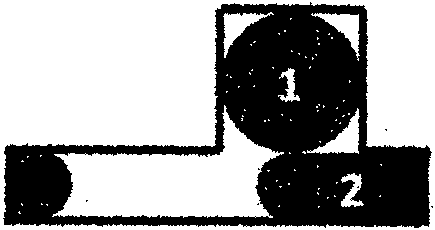

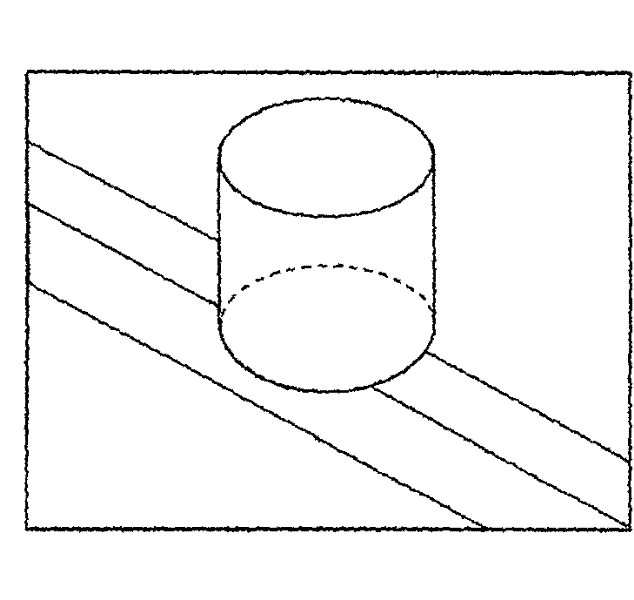

[0031] The continuously generated droplets continue to flow under the drive of the syringe pump and enter the droplet catcher array. When the droplets flow through the lower channel of the catcher, they enter the cylindrical catcher upwards due to the combined action of buoyancy and surface tension. It flows through the lower channel and is sequentially captured in the droplet catcher of the cylinder;

[0032] After the droplets w...

Embodiment 2

[0037] The high-throughput micro-droplet immobilization method on a microfluidic chip based on the principles of buoyancy and surface tension uses a dedicated microfluidic chip. The lower layer is the T-shaped droplet generation area and the droplet evacuation channel.

[0038] In the specific operation, we connect the continuous phase and dispersed phase inlets on the chip to two syringe pumps respectively through Teflon tubes (the density of the continuous phase is greater than that of the dispersed phase), and driven by the syringe pump, the continuous phase and dispersed phase The phases are injected into the chip separately, and continuous monodisperse microdroplets are formed in the lower T-shaped microdroplet generation area; the generated microdroplets continue to flow into the droplet catcher array, and are sequentially one by one under the combined action of buoyancy and surface tension. Captured in the upper cylindrical droplet catcher.

[0039] The dedicated micro...

Embodiment 3

[0041] A high-throughput micro-droplet fixing method, based on the principles of buoyancy and surface tension, is manipulated on a microfluidic chip; the micro-droplet fixing method is specifically:

[0042] The continuous phase and dispersed phase inlets on the chip are respectively connected to two syringe pumps through Teflon tubes. Driven by the syringe pump, the continuous phase and the dispersed phase are injected into the chip respectively, and then the T-shaped droplets are formed in the generation area. Continuous monodisperse droplets (the density of the continuous phase is greater than the density of the dispersed phase);

[0043]The continuously generated microdroplets continue to flow under the drive of the syringe pump and enter the droplet catcher array. When the droplets flow through the lower channel of the catcher, they enter the cylindrical catcher upwards due to the combined action of buoyancy and surface tension; The lower channel of the droplet catcher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com