A kind of method that solid carbon source prepares graphene

A solid carbon source, graphene technology, applied in graphene, single-layer graphene, chemical instruments and methods, etc., to achieve the effect of good operability, high quality, and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

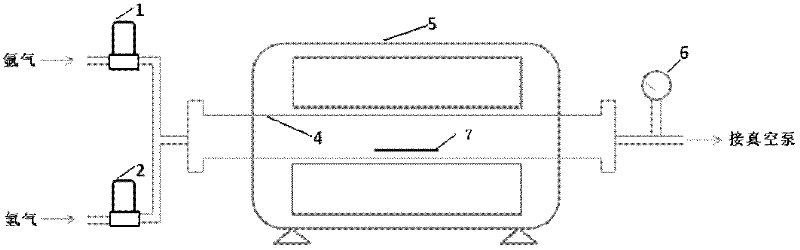

[0038] The present invention adopts pyrolysis solid carbon source to form graphene film by crystallization on metal substrate, comprising the following preparation steps:

[0039] 1. Take a 20 mm square flat metal copper foil and fix it on the glass;

[0040] 2. Fix the glass sheet on the centrifugal glue machine;

[0041] 3. Spray 0.1 ml of PMMA (solid carbon source polymethyl methacrylate) on the surface of the metal substrate.

[0042] 4. Set the rotating speed of the glue machine to 500 rpm and the time to 30 minutes.

[0043] 5. Remove the metal substrate on the glass slide, and heat it to 30 degrees Celsius on a heating plate for 60 minutes.

[0044]6. The metal substrate 7 sprayed with solid carbon source is placed in the quartz tube 4;

[0045] 7. Pump the air pressure of the quartz tube 4 to the limit vacuum state 4×10 -2 Torr;

[0046] 8. Set the gas flow rate of the inert gas flow meter 2 to 5 sccm, and inject the inert gas into the quartz tube 4;

[0047] 9....

Embodiment 2

[0056] The present invention adopts pyrolysis solid carbon source to form graphene film by crystallization on metal substrate, comprising the following preparation steps:

[0057] 1. Take a 50 mm square flat metal nickel foil and fix it on a glass slide;

[0058] 2. Fix the glass sheet on the centrifugal glue machine;

[0059] 3. Spray 10 ml of PDMS (solid carbon source polydimethylsiloxane) on the surface of the metal substrate.

[0060] 4. Set the rotating speed of the glue machine to 10000 rpm and the time to 30 seconds.

[0061] 5. Remove the metal substrate on the glass slide and heat it on a heating plate at 200 degrees Celsius for 10 seconds.

[0062] 6. The metal substrate 7 sprayed with solid carbon source is placed in the quartz tube 4;

[0063] 7. Pump the air pressure of the quartz tube 4 to the ultimate vacuum state of 8×10 -2 Torr;

[0064] 8. Set the gas flow rate of the inert gas flow meter 2 to 100 sccm, and inject the inert gas into the quartz tube 4; ...

Embodiment 3

[0074] The present invention adopts pyrolysis solid carbon source to form graphene film by crystallization on metal substrate, comprising the following preparation steps:

[0075] 1. Take a 30 mm square flat metal copper foil and fix it on the glass;

[0076] 2. Fix the glass sheet on the centrifugal glue machine;

[0077] 3. Spray 5 ml of PMMA (solid carbon source polymethyl methacrylate) on the surface of the metal substrate.

[0078] 4. Set the rotating speed of the glue machine to 5000 rpm and the time to 10 minutes.

[0079] 5. Remove the metal substrate on the glass slide, and heat it to 100 degrees Celsius on a heating plate for 10 minutes.

[0080] 6. The metal substrate 7 sprayed with solid carbon source is placed in the quartz tube 4;

[0081] 7. Pump the air pressure of the quartz tube 4 to the ultimate vacuum state of 6×10 -2 Torr;

[0082] 8. Set the gas flow rate of the inert gas flow meter 2 to 50 sccm, and inject the inert gas into the quartz tube 4;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com