A vertical pipe gushing boiling seawater evaporator

A seawater evaporation and evaporator technology, which is applied in the field of vertical pipe spouting boiling seawater evaporators, can solve the problems of adverse effects of falling film evaporation process, destroying the advantages of high heat transfer coefficient, drying up, etc., achieving simple structure and reducing power consumption. , the effect of reducing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

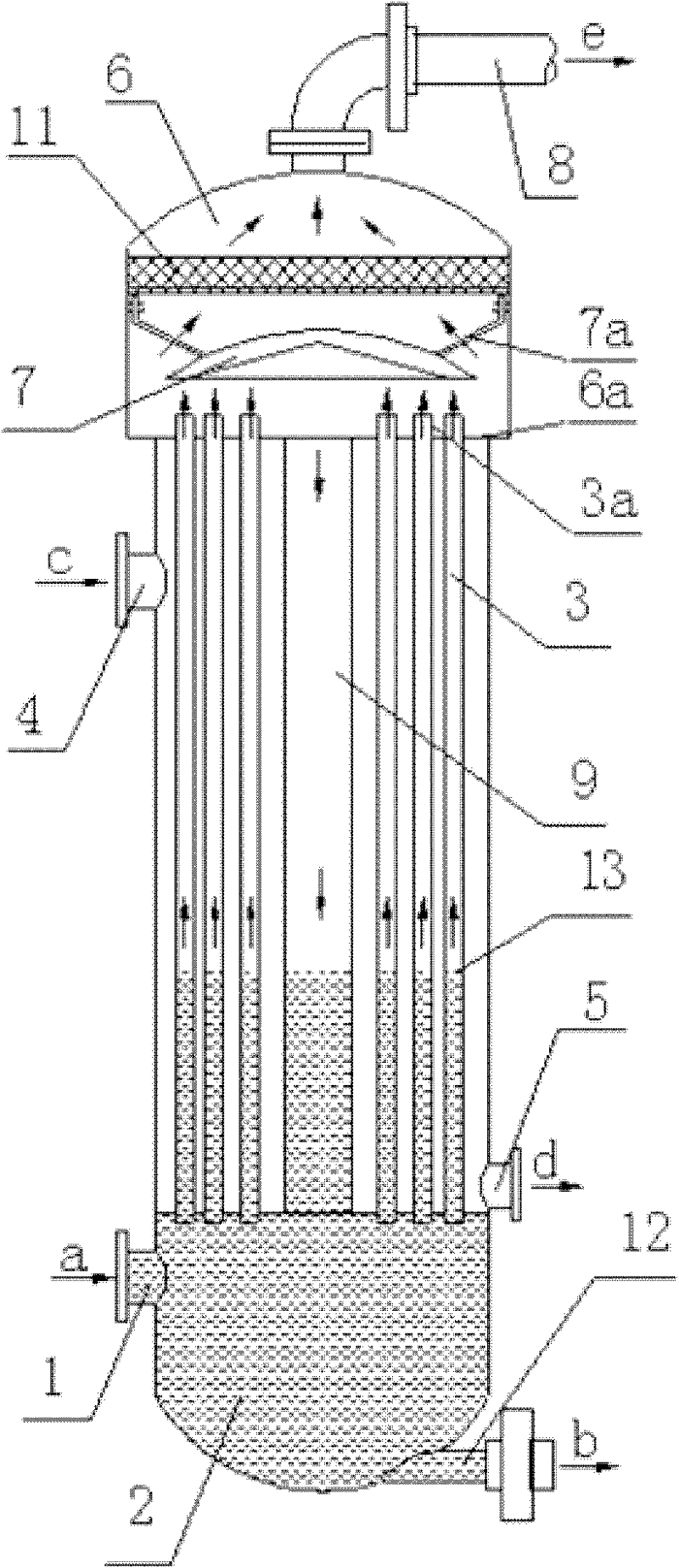

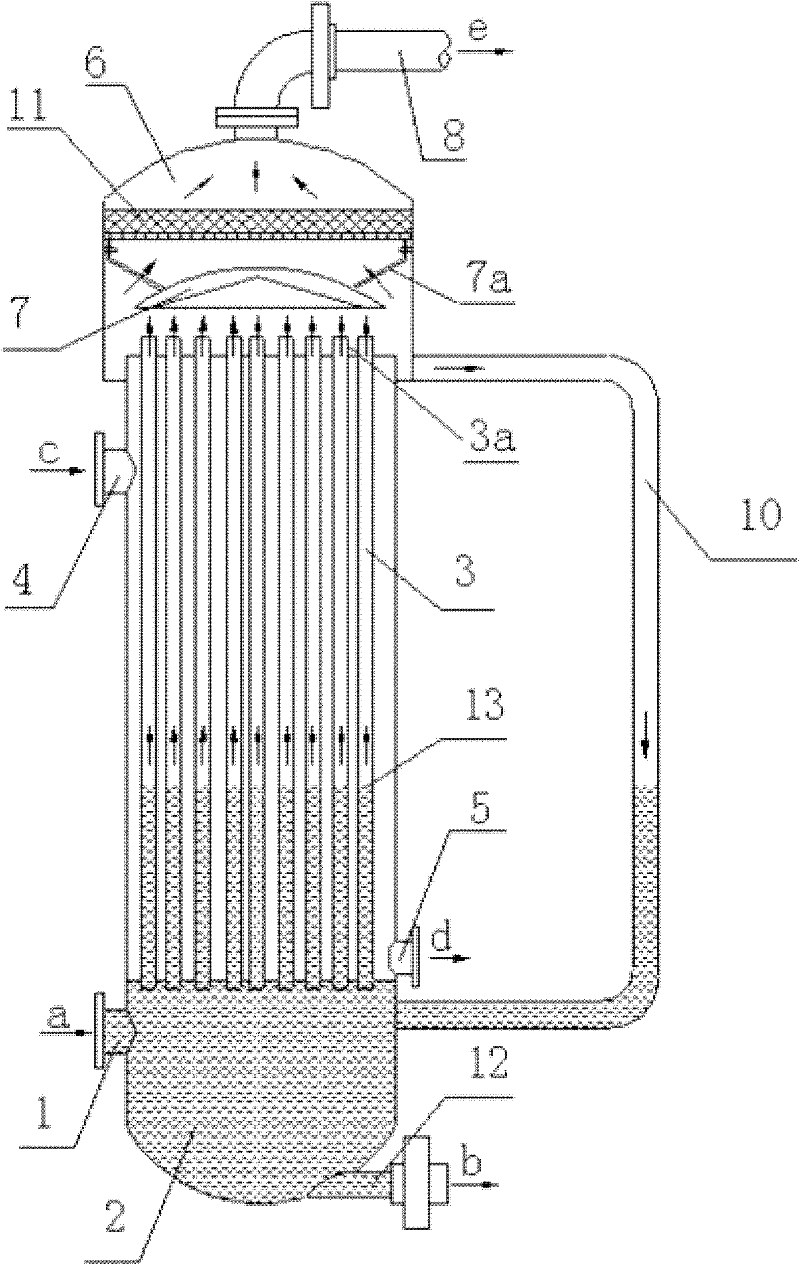

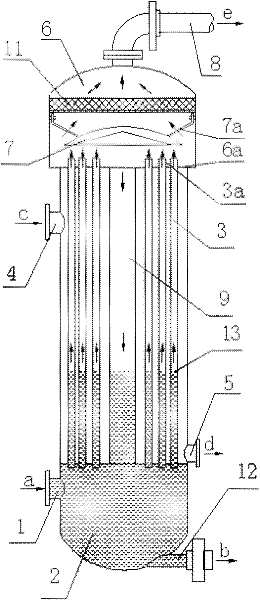

[0017] The structure of the present invention will be further described below with reference to the accompanying drawings.

[0018] figure 1 , 2 A structure diagram of a standpipe gushing boiling seawater evaporator with an internal downcomer is shown. In the figure, the vertical pipe gushing boiling seawater evaporator adopts a tower structure, and the evaporating tube bundles 3 are distributed vertically and evenly along the circumference of the heat exchange box, and are connected with the lower tube box 2 and the upper tube box 6, and the tube sheets of the upper and lower tube boxes The standpipe gushing boiling seawater evaporator is divided into three airtight boxes. Feed seawater a enters the lower pipe box 2 through the seawater inlet pipe 1 opened on the side of the lower pipe box 2, and then enters the heat exchange box along the evaporator tube bundle 3 to exchange heat with the shell-side heating fluid. After boiling, the seawater gushes to the upper pipe box 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com