A waste acid recovery process and its supporting equipment

An acid recovery and process technology, applied in chlorine/hydrogen chloride, water/sludge/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of high energy consumption, low operating cost, secondary pollution, etc. Difficult to clean, ensure stability, overcome the effect of easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

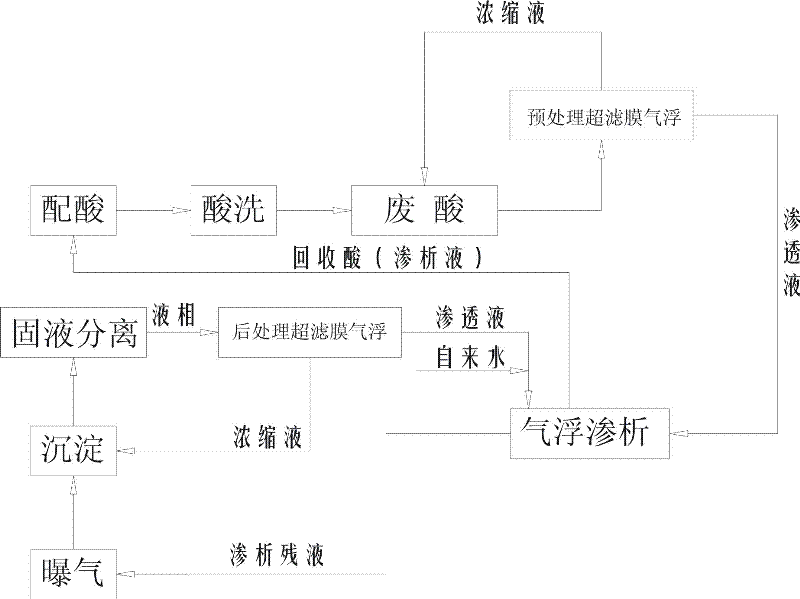

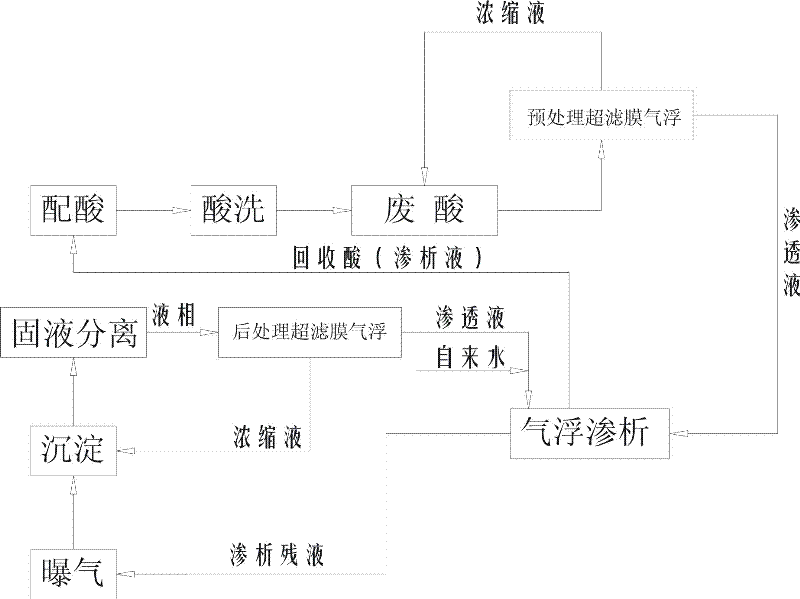

[0027] A waste acid recovery process, such as figure 1 As shown, after acid preparation and pickling, the waste acid is processed through the following steps:

[0028] 1) Pretreatment of waste acid by ultrafiltration membrane air flotation: install ultrafiltration membrane modules vertically, then use gas-liquid hybrid power device to supply waste acid from the lower part of ultrafiltration membrane modules, and use ultrafiltration membrane air flotation to purify and remove Among them, large particle pollutants such as oil, silicon powder, and carbon; the concentrated liquid (gas-acid mixture) discharged from the ultrafiltration membrane module is collected into the untreated waste acid for recycling.

[0029] 2) Air flotation dialysis: use the gas-liquid hybrid power device to feed the pretreated waste acid into the dialyzer for air flotation dialysis. The dialysate is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com