A wind energy steam boiler unit

A technology of steam boiler and wind energy, which is applied in wind turbine combination, wind energy power generation, steam generation, etc., can solve the problems of leftover fuel residue, consumption of large and high-grade energy, unfavorable environmental protection and energy saving, etc., so as to save electric energy loss and improve steam production efficiency. , the effect of stabilizing the freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

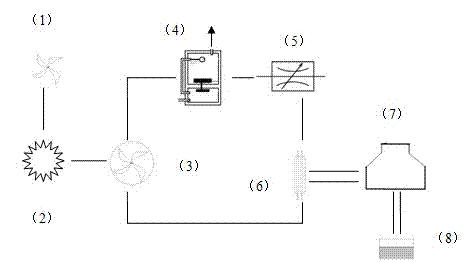

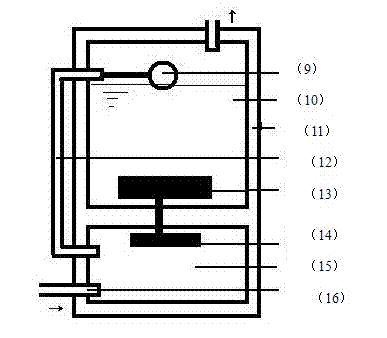

[0012] in the attached figure 1 In the middle, the ambient wind blows the wind blade (1), and the rotation of the wind blade drives the planetary gear transmission (2). The planetary gear transmission amplifies the rotation of the wind blade, and the high-speed mechanical energy drives the operation of the compressor (3). The working fluid is compressed to realize the gas phase change of the working fluid. The gaseous working medium enters the steam boiler (4) to liquefy and release heat to produce steam, and then enters the evaporator (6) through the throttle valve (5) and throttles at the throttle valve. Under the action of the working medium, it becomes a high-pressure liquid, evaporates and absorbs heat in the evaporator, and exchanges heat with the cooling tower (7) to absorb environmental energy, and then enters the compressor for compression to complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com