Surface conduction electron emission source based on oxide nanostructure and its manufacturing method

A nano-structured, electron-conducting technology, applied in electrode system manufacturing, discharge tube/lamp manufacturing, cathode ray tube/electron beam tube, etc., can solve the problems of complex manufacturing process, low emission efficiency, low electron emission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

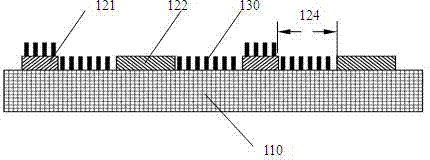

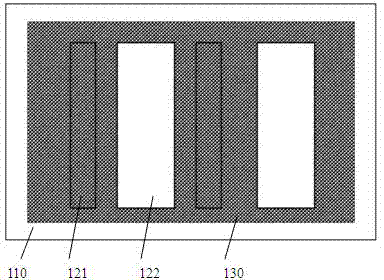

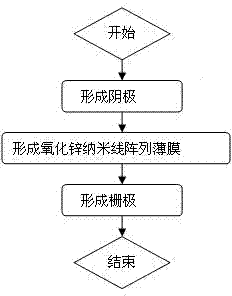

[0058] A method for preparing a surface conduction electron emission source based on zinc oxide nanowires provided in the first embodiment of the present invention includes the following steps:

[0059] Step 1, refer to Figure 4 , form the cathode electrode 121 on the surface of the substrate 110, and the material used for the cathode electrode 121 can be photosensitive silver paste, Cu, W, Co, Ni, Ta, TaN, Ti, Zn, Al, or other metal electrodes. The present embodiment preferably adopts photosensitive silver paste, and its specific process includes:

[0060] (a) Spin coating of photosensitive silver paste: the photosensitive silver was transferred to the surface of the substrate 110 by using a spin coating process, and kept at 110° C. for 20 minutes. The substrate used can be selected from glass, quartz, ceramics, and high temperature resistant materials with an insulating layer on the surface;

[0061] (b) Exposure: The pre-dried photosensitive silver paste film layer is na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com