Thermal radiation heat dissipation light-emitting diode structure and manufacturing method thereof

A technology of a light-emitting diode and a manufacturing method, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of increasing the weight of the LED structure 1, increasing the size of the LED structure 1, and the LED structure 1 being cumbersome, etc., so as to increase the application range and Ease of use, reduced material and production costs, reduced volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

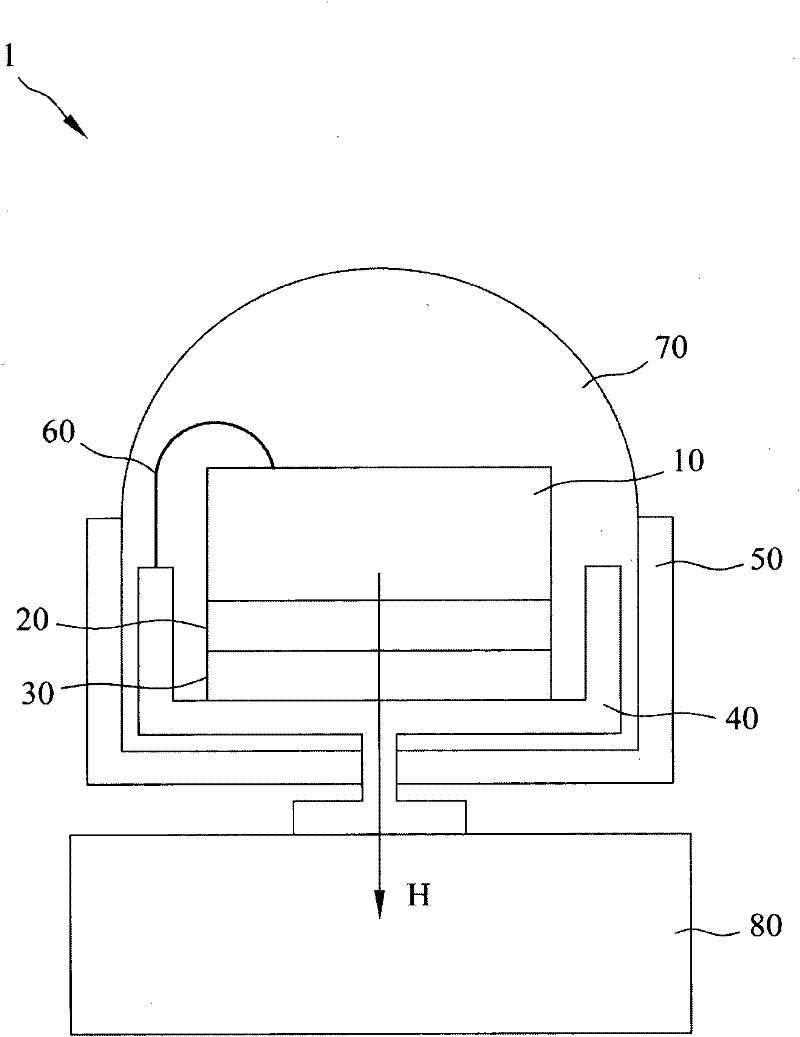

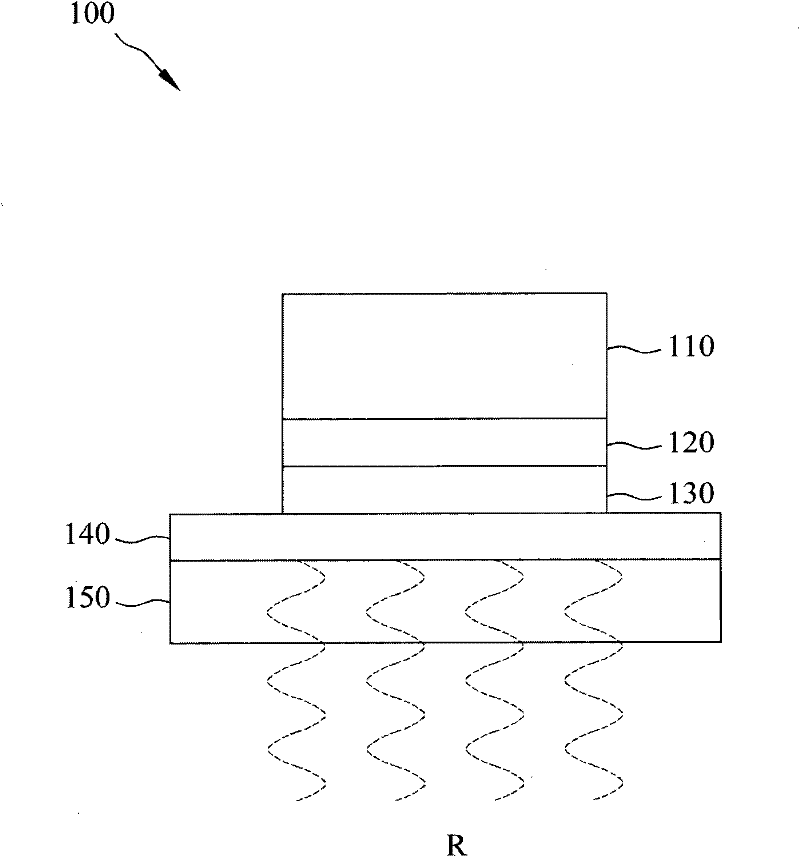

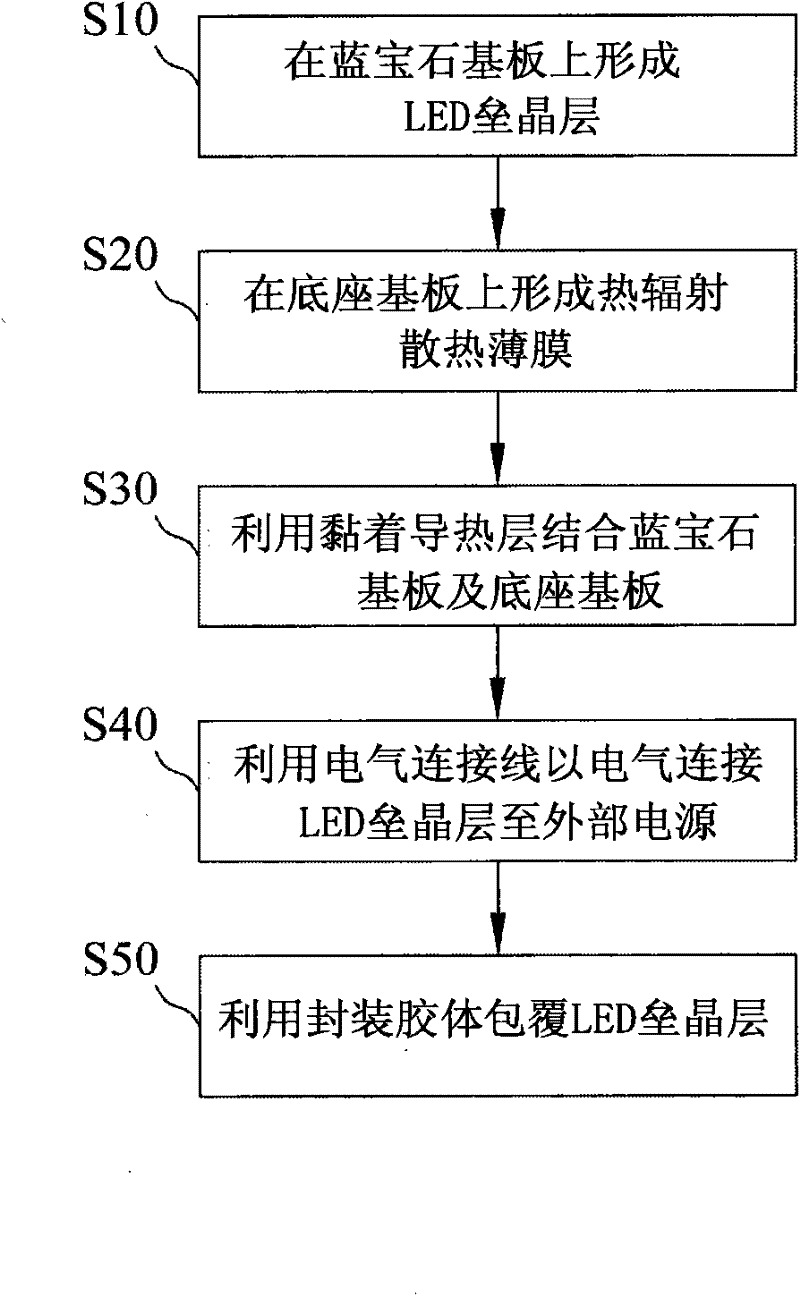

[0014] refer to figure 2 , is a schematic diagram of the structure of the thermal radiation heat dissipation light-emitting diode of the present invention. Such as figure 2 As shown, the thermal radiation heat dissipation LED structure 100 of the present invention includes an LED epitaxial layer 110, a sapphire substrate 120, an adhesive heat conduction layer 130, a thermal radiation heat dissipation film 140, a base substrate 150, and at least one electrical connection line (not shown in the figure) and packaging colloid (not shown in the figure). The LED epitaxial layer 110 generally can at least include an N-type semiconductor layer, a semiconductor light-emitting layer, and a P-type semiconductor layer stacked in sequence. For example, the N-type se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com