High-reflectivity reflecting film and manufacturing method thereof

A technology of high reflectivity and reflective film, which is applied in the field of reflective film, can solve the problems that the reflective film is easy to scratch, the porosity should not be too large, and cannot be further improved, so as to improve convenience, avoid uneven brightness, and increase the interlayer Effects of Interface Differences and Refractive Index Differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

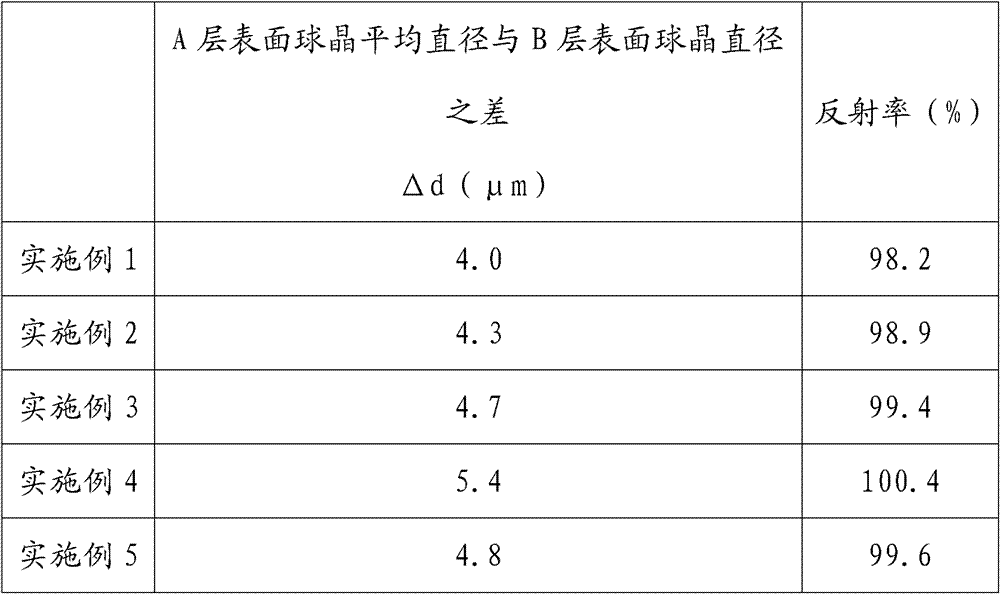

Embodiment 1

[0054] Pre-crystallize and dry polyester A layer raw materials and polyester B layer raw materials at a temperature of about 180°C, mix them uniformly and transport them to the extruder; among them, the A layer raw materials are 100 parts of polyester and 2wt% TiO 2 (average particle diameter 3 μ m) and auxiliary agents such as antioxidant, heat stabilizer, light stabilizer; B layer raw material is 100 parts of polyester and 12wt% BaSO 4 (average particle size is 0.7μm, surface treated with polyethylene glycol), 8wt% polymethacrylic acid particles (average particle size 1.2μm), 10wt% polymethylpentene, 0.01wt% 2,4-dihydroxydi Benzophenone and 0.01wt% 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, and auxiliary agents such as antioxidant and heat stabilizer, also contain 0.5wt% ethylene-methyl Sodium acrylate copolymer, 2.0 wt% polyethylene glycol and 3.5 wt% sodium benzoate.

[0055] In the above-mentioned extruder, the raw material is melted and extruded at a temperature of abo...

Embodiment 2

[0060] Except that the content of the ethylene-sodium methacrylate copolymer added in the B layer is changed to 0.7wt%, the content of polyethylene glycol is changed to 2.3wt%, and the content of sodium benzoate is changed to 3.0wt%. Conditions to make a reflective film.

Embodiment 3

[0062] Except that the content of the ethylene-sodium methacrylate copolymer added in the B layer is changed to 1.0wt%, the content of polyethylene glycol is changed to 4.0wt%, and the content of sodium benzoate is changed to 1.0wt%. Conditions to make a reflective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com