A titanium-aluminum-based alloy suitable for casting with excellent high-temperature oxidation resistance and creep performance

A high-temperature oxidation resistance and creep performance technology, which is applied in the field of titanium-aluminum-based alloys, can solve the problems of poor high-temperature creep performance and high-temperature oxidation resistance of titanium-aluminum alloy materials, and achieve improved oxidation resistance, room temperature, and fineness. Effect of ply spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

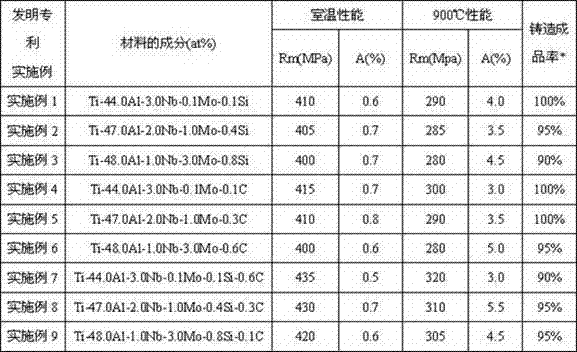

Examples

Embodiment Construction

[0030] The titanium aluminum material of the present invention all adopts sponge titanium, pure Al, AlNb50 alloy, AlMo60, AlSi10 alloy, pure C powder as raw material, carries out batching according to the composition and content requirement of embodiment 1--embodiment 9, in vacuum induction furnace Melt and cast turbine formwork. The smelting method of titanium-aluminum ingots for casting is as follows: first, vacuumize to 3.5Pa, and melt the raw materials of the new titanium-aluminum alloy material with argon pressure at 60,000 Pa. The ingot is repeatedly smelted 2 times. The casting process of the turbine formwork is as follows: the pre-vacuum degree is 3.5Pa, and the titanium-aluminum ingot is completely melted and then stirred for 2 minutes before casting the turbine formwork.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com