Loading method and application of a metal surface corrosion inhibitor

A metal surface, corrosion inhibitor technology, applied in anodizing and other directions, can solve the problems of limited corrosion inhibitor dose, insignificant corrosion inhibition effect, difficulty in ensuring doping uniformity, etc., and achieve the effect of high loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The 2024 aluminum alloy electrode sheet is subjected to electrostatic sanding of No. 80, 120, and 400 in turn, and mechanically polished with No. 14 metallographic sandpaper. It is placed in a 60°C degreasing solution for 5 minutes, and then ultrasonicated at 60°C for 10 minutes. Finally, tap water is used sequentially. After cleaning the electrode with deionized water, quickly dry it with hot air, and place it in a dry box for 24 hours before use.

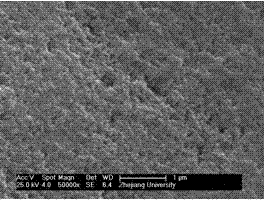

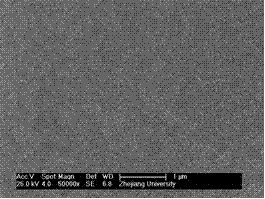

[0035] Add 50mL of absolute ethanol, 50mL of water, 3mL of tetraethyl orthosilicate (TEOS) to the beaker in turn, adjust the pH to about 3.0 with HCl, stir at room temperature for 2~3h and set aside. Add the prepared precursor solution into the three-electrode tank, use the 2024 aluminum alloy electrode as the working electrode, Ag / AgCl as the reference electrode, platinum as the counter electrode, control the potential at -1.5V, and set the deposition time to 300s. After rinsing with deionized water, dry at 40°C to obtain a ...

Embodiment 2

[0041] The specific implementation steps are as in Example 1, the subsequent protective layer is changed, and the DTMS silane film is replaced with an epoxy coating. The ratio of the epoxy coating solution is: the mass ratio of epoxy resin, polyamide resin, solvent (n-butanol:xylene volume ratio = 3:7) = 5:4:8. Brush the epoxy solution on the pretreated aluminum alloy substrate, and place it at 40°C for one week to cure. The thickness of the resulting coating is about 40±2 μm.

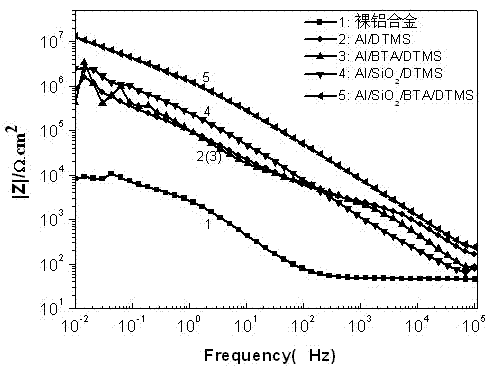

[0042] In addition to using electrochemical impedance spectroscopy (EIS) technology for testing, the test solution used is 3.5wt% NaCl aqueous solution, and the evaluation of the coating also adopts the accelerated test method, that is, boiling water immersion test: the metal / coating system is placed After 8 hours in boiling deionized water, stop boiling, take out the sample, and observe the foaming and delamination of the coating. Table 2 lists the low-frequency impedance modulus and boiling water t...

Embodiment 3

[0047] The specific implementation steps are as in Example 1, changing the substrate to low-carbon steel. The difference is that the low-carbon steel substrate does not need to be sanded, and the degreasing step is directly performed. In addition, the corrosion inhibitor was changed from BTA to thiourea suitable for steel. In addition to the evaluation of the protective layer by electrochemical impedance spectroscopy, damp heat experiments are also used for accelerated evaluation. The latter is carried out in a constant temperature and humidity chamber with a controlled temperature of 40°C and a humidity of 90%, and the corrosion status of the sample surface is regularly observed. The specific test results are listed in Table 3.

[0048] Table 3 Low-frequency impedance modulus and damp heat test results of different low-carbon steel / DTMS protective layer systems

[0049] sample |Z| / Ω·cm 2 (f=0.1Hz) Red rust time in damp heat test / h Bare mild steel subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com