Method and apparatus for testing ice adhesion strength

A technology of adhesion strength and testing method, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inability to effectively control the amount of icing on the interface, the quality of icing on the surface, poor test repeatability, and large error in test repetition. , to achieve the effect of guaranteed test repeatability, accurate test results and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

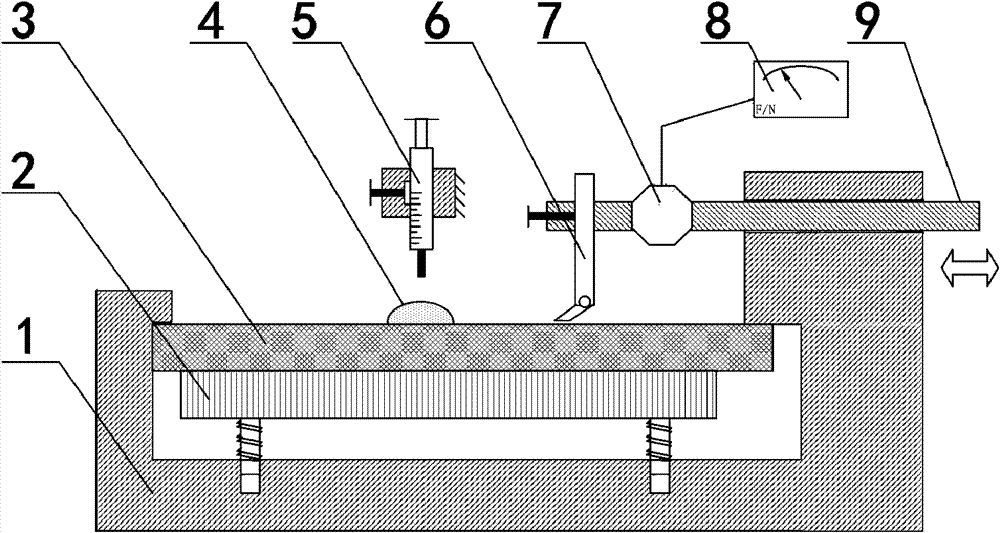

[0024] The invention discloses a method and device for testing ice adhesion strength, which characterizes the surface ice adhesion strength by testing the maximum tangential force when the peeled solid surface freezes. Different from existing ice adhesion (or icing) strength test methods: in the method disclosed by the present invention, the process of simulating surface icing adopts the cooling sample first, and then titrates liquid water to make it freeze on the sample surface; to be tested ( Peeling) Icing is an "ice convex hull" formed by quantitative titration of liquid water; the peeling process uses a push plate with a force sensor to push the "ice convex hull" to peel off the surface to be tested or break the ice inside; Therefore, there is no need to consider the icing form formed by quantitative liquid droplets on the surface of the sample to be tested (due to the difference in surface energy at room temperature, the shape of the convex hull of water on different soli...

Embodiment 2

[0033]The invention discloses a device implementation method description. The specific implementation method and key content of the test device for the method disclosed in the present invention are as follows: the refrigeration unit and the frame are connected by a spring, and when the test piece is placed in the fixed frame, the spring under the refrigeration unit is deformed and stressed, so that the lower surface of the sample is in contact with the refrigeration unit. In close contact, the upper surface is accurately embedded in the fixed frame to maintain the test position; the temperature of the refrigeration unit is controlled by the automatic temperature controller, and the temperature is specified and constant according to the test requirements; the water titration unit is set above the upper surface of the sample, which can precisely control the water droplets Quantitative, in order to repeat the test for a single sample at the same time, multiple continuous or movabl...

Embodiment 3

[0035] The invention discloses specific instructions for use of the device. The device disclosed by the invention can be used in the fields of material ice adhesion strength test, coating ice adhesion strength test, ice adhesion test of different shapes (smooth, rough, regular non-smooth) and related parameters, and can be used for engineering material selection and engineering anti-corrosion. Provide a reference for the research and development of icing materials, coatings, and surfaces. As a test device for the surface properties of materials, the specific operation steps of the ice adhesion strength test device disclosed in the present invention are as follows:

[0036] (1) Push the test piece 3 into the middle of the sample holder 1 and the refrigeration unit 2, and fix the test piece 3.

[0037] (2) Start the refrigeration unit 2 at the bottom of the test piece, and quickly cool the test piece 3 to reach the predetermined refrigeration temperature (according to the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com