Fabrication method of silicon-based thin film solar cell integrated inline module on flexible substrate

A technology of solar cells and silicon-based thin films, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of complex splicing of components, large sheet resistance, and poor light transmission performance, so as to simplify complexity and increase open circuit voltage , The effect of accelerating the process of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

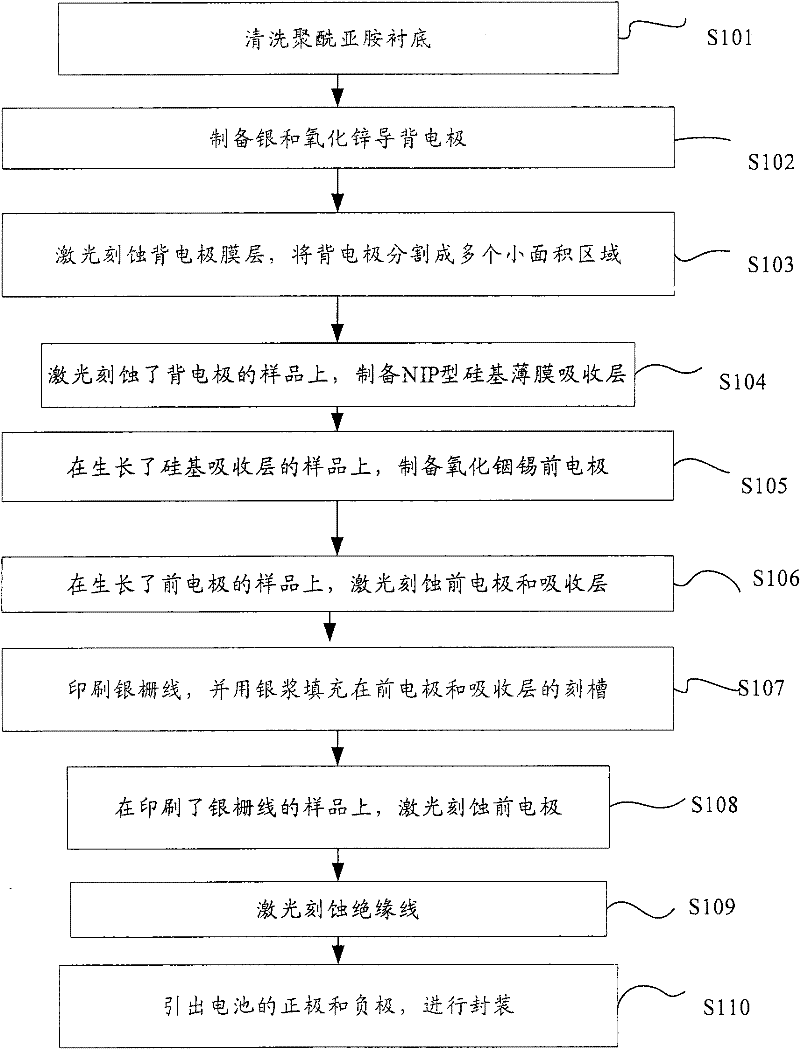

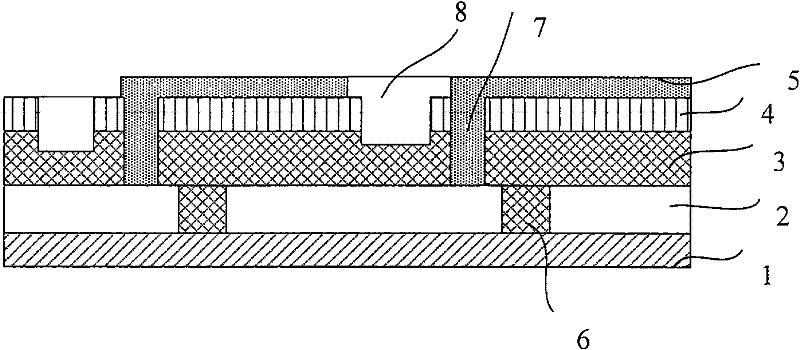

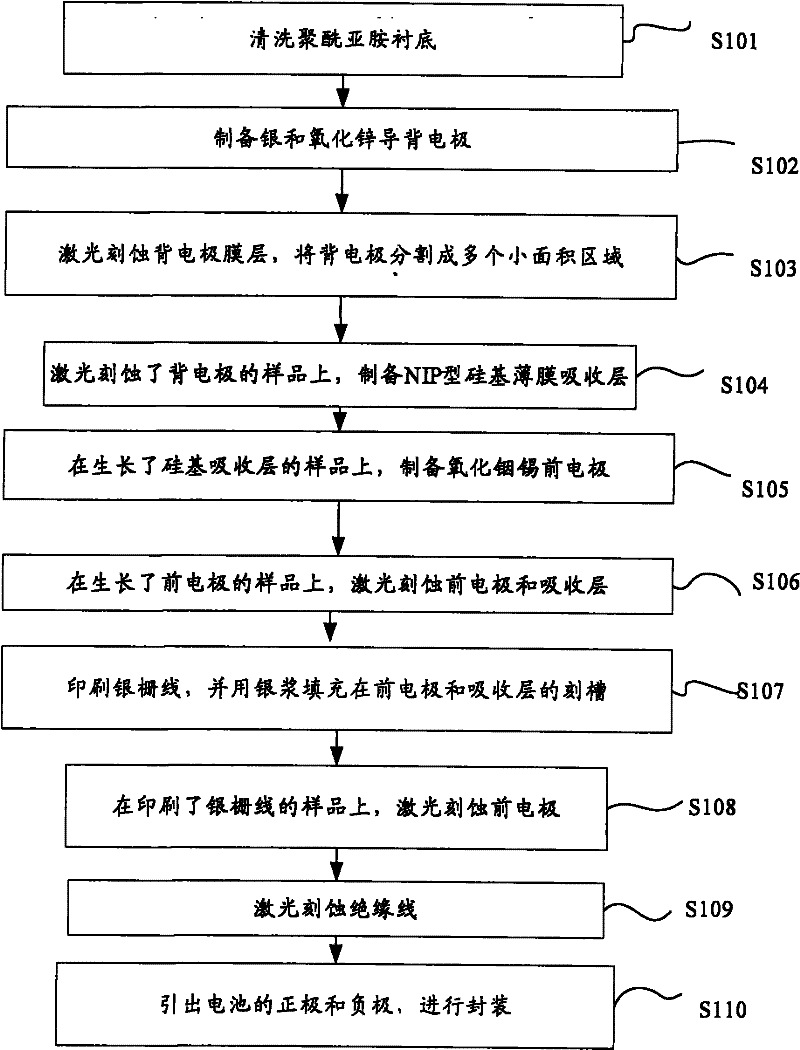

[0062] Put the polyimide substrate into the ethanol solution, ultrasonically vibrate for 15 minutes, and vibrate three times. Dry the cleaned polyimide substrate with nitrogen, put it into the magnetron sputtering equipment, and bake it in a high vacuum state at 400°C for one hour; The zinc oxide layer is sputtered in high vacuum at 200°C, and the total thickness of the back electrode film is about 900nm. A 1064nm laser is used to etch the silver / zinc oxide back reflection layer (groove 6), and the etching line width is about 30 μm.

[0063] N, I, P three-layer films were deposited in three different reaction chambers of PECVD equipment. After the deposition of the amorphous silicon thin film, the battery sample was naturally cooled to room temperature and taken out from the PECVD equipment. Put it into the magnetron sputtering equipment, under the high vacuum state of 100 ℃, prepare the transparent front electrode of indium tin oxide, and the thickness of the film layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com