A kind of preparation method of high-purity epigallocatechin

A technology of gallocatechin and purity table, which is applied in the field of preparing high-content epigallocatechin, can solve the problems of high preparation cost, and achieve the effects of low production cost, simple and convenient operation, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

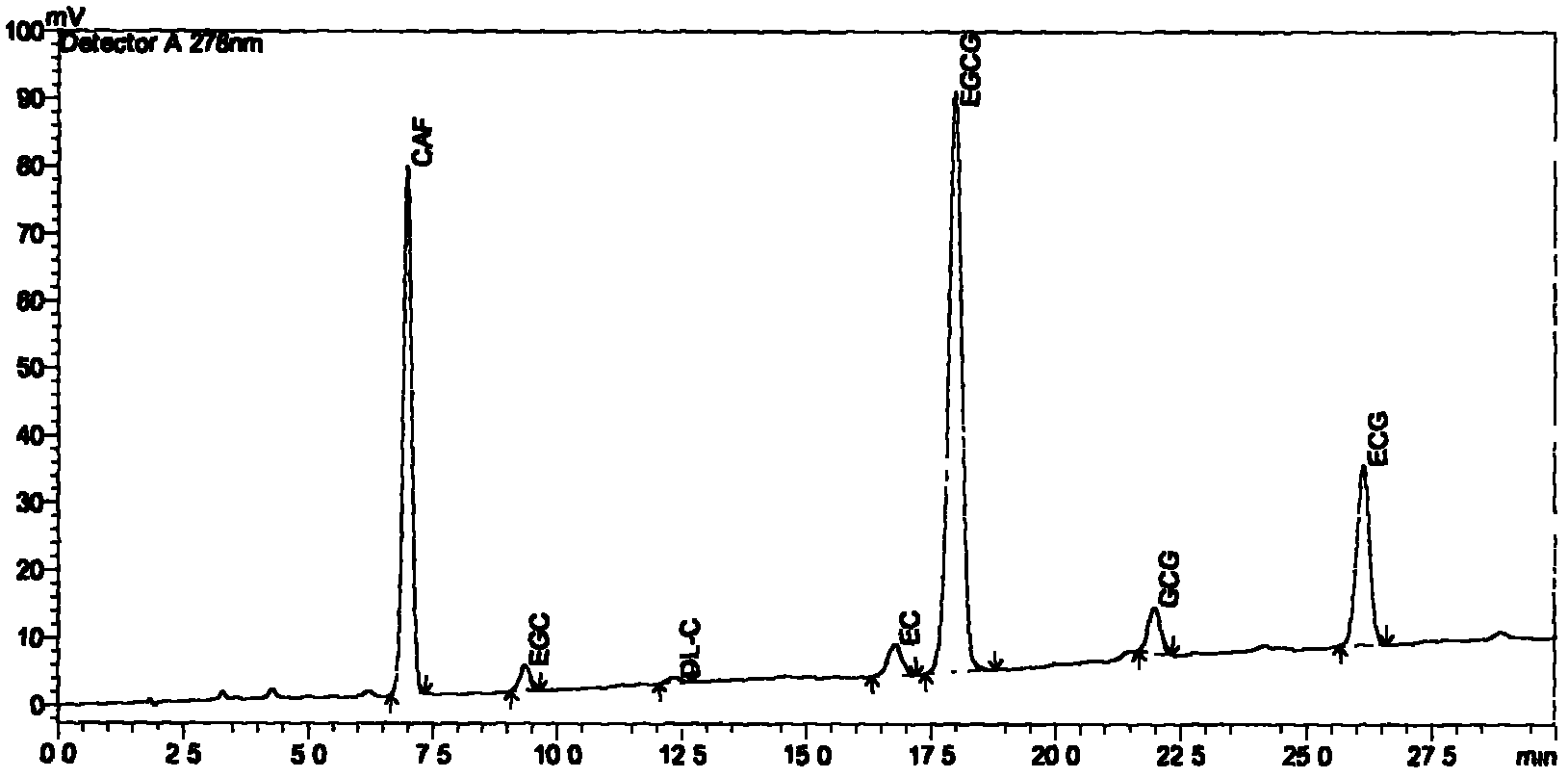

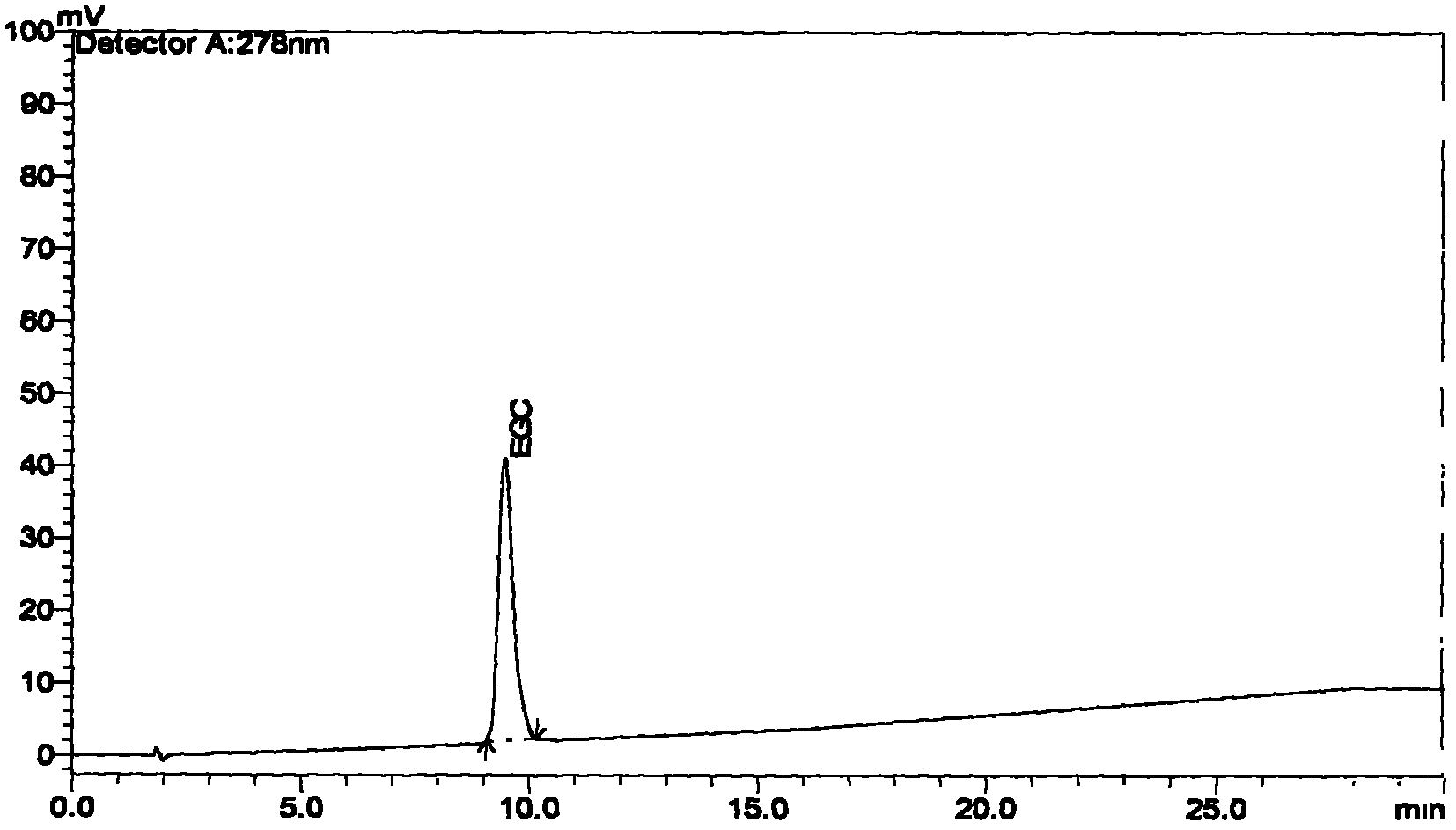

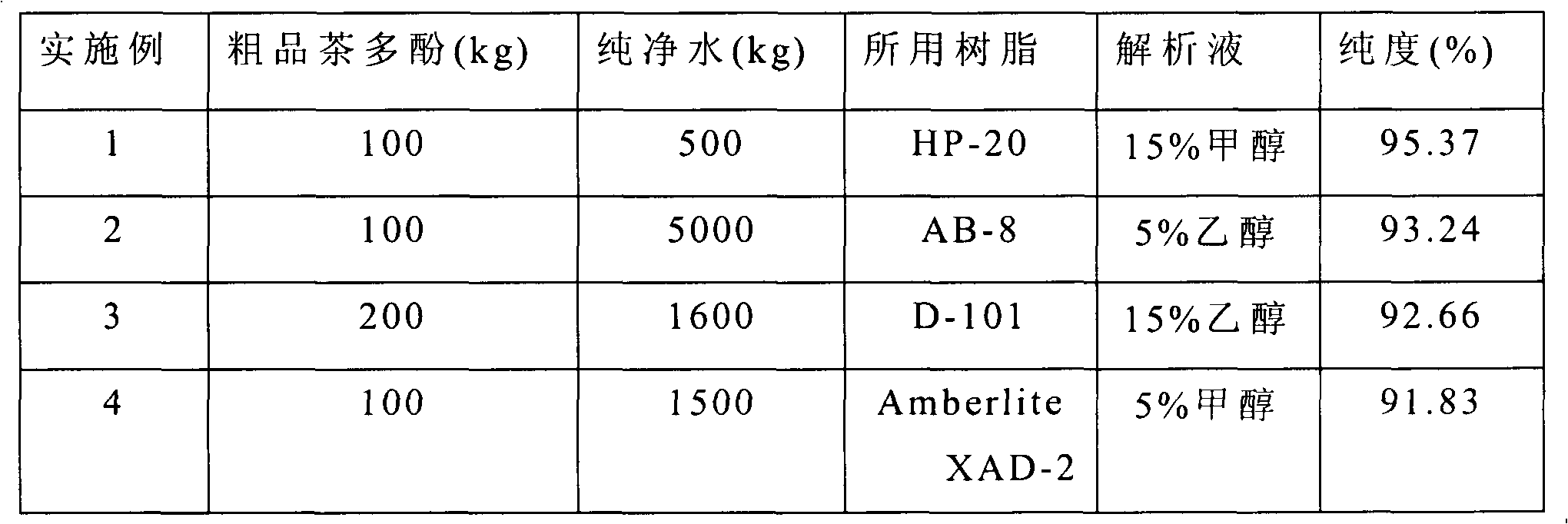

[0024] Add 100kg of crude tea polyphenol raw material (EGC content is 9.87%) to 500kg of pure water, heat to dissolve, filter after cooling, and the filtrate passes through the macroporous adsorption resin model HP-20 at a flow rate of 0.8 times column volume / hour. Then wash the resin with 8 times the pure water of the column volume; analyze with 15% methanol of 5 times the column volume at a flow rate of 1 column volume / hour, collect the analysis solution, concentrate to 5-30%, and concentrate the solution at 4 Place at ℃ for 24 hours to crystallize; wash the crystals with a small amount of pure water, filter and dry by freeze-drying to obtain powdery EGC. Gained EGC sample carries out purity, and its detection instrument is Agilent1100 high-performance liquid chromatography (Agilent Corporation of the U.S.), and chromatographic column is Shim-pack ODS C18 post (4.6 * 150mm, 5 μ m), mobile phase mobile phase: A phase, water; B Phase, formamide: methanol: glacial acetic acid 4...

Embodiment 2

[0026] Add 100kg of crude tea polyphenol raw material (EGC content is 9.87%) to 5000kg of pure water, heat to dissolve, filter after cooling, and the filtrate passes through the macroporous resin model AB-8 at a flow rate of 1 column volume / hour. Then wash the resin with 10 times the pure water of the column volume; analyze with 5% ethanol 3 times the column volume at a flow rate of 0.8 times the column volume / hour, collect the analysis solution, concentrate to 5-30%, and concentrate the solution at 4 Place at ℃ for 24 hours to crystallize; wash the crystals with a small amount of pure water, filter and dry by freeze-drying to obtain powdery EGC. The EGC content was detected by HPLC to reach 93.24%, and the results are shown in Table 1.

Embodiment 3

[0028] Add 200kg of crude tea polyphenol raw material (EGC content is 9.87%) to 1600kg of pure water, heat to dissolve, filter after cooling, and the filtrate passes through the macroporous resin of model D-101 at a flow rate of 0.8 times column volume / hour. Then wash the resin with 5 times the pure water of the column volume; then analyze with 15% ethanol 2 times the column volume at a flow rate of 0.8 times the column volume / hour, collect the analysis solution, concentrate to 5-30%, and concentrate the solution at 4 Place at ℃ for 24 hours to crystallize; wash the crystals with a small amount of pure water, filter and dry by freeze-drying to obtain powdery EGC. The EGC content was detected by HPLC to reach 92.66%, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com