Lost foam digital processing method and its equipment

A technology of processing equipment and processing methods, which is applied in the direction of metal processing equipment, milling machine equipment, milling machine equipment details, etc., can solve the problems of shortening the production time of lost foam patterns, low precision and quality, waste of raw materials, etc., and achieve shortening research and development cycle, precision And the effect of high quality and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

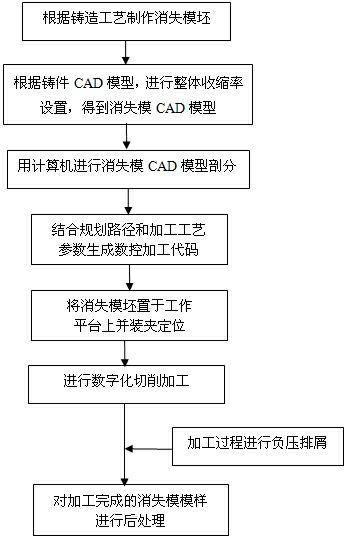

[0026] According to the requirements of the casting process, select the appropriate lost foam bead material to manufacture the lost foam blank for CNC machining; according to the casting CAD model, set the overall shrinkage rate to obtain the lost foam CAD model; divide the lost foam CAD model , to reserve the bonding gap of the lost foam blank or process a hole or column for positioning; generate a processing code acceptable to the processing equipment according to the planned path combined with the processing parameters; digitize the suitable lost foam blank after positioning on the working platform Cutting processing; post-processing of the finished lost foam pattern.

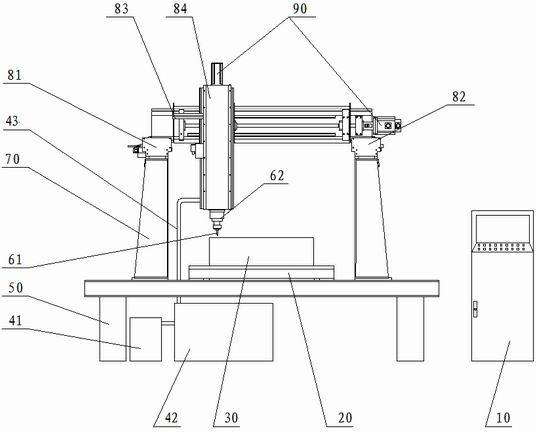

[0027] The lost foam digital processing equipment according to the present invention includes a base 50; a bed 70 connected to the base 50; a working platform 20 installed on the base 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com