Repair process for cavitation corrosion of runner chamber of through-flow type water turbine

A technology for a tubular water turbine and a runner chamber, which is applied in the field of repair technology, can solve the problems of inapplicable cavitation repair of the runner chamber, affecting the working quality of the runner chamber, and limited operating life of the hydraulic turbine, etc., so as to achieve reliable repair quality and eliminate the The effect of stress concentration and extended operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

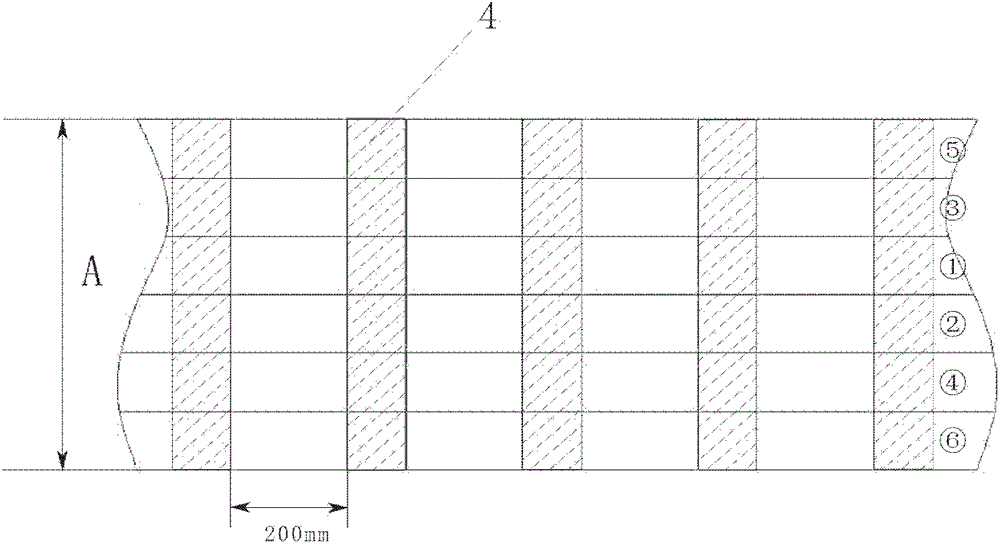

[0025] Attached below Figure 1~3 A detailed description of an implementation of the on-site cavitation repair process for the runner chamber of the tubular turbine according to the present invention:

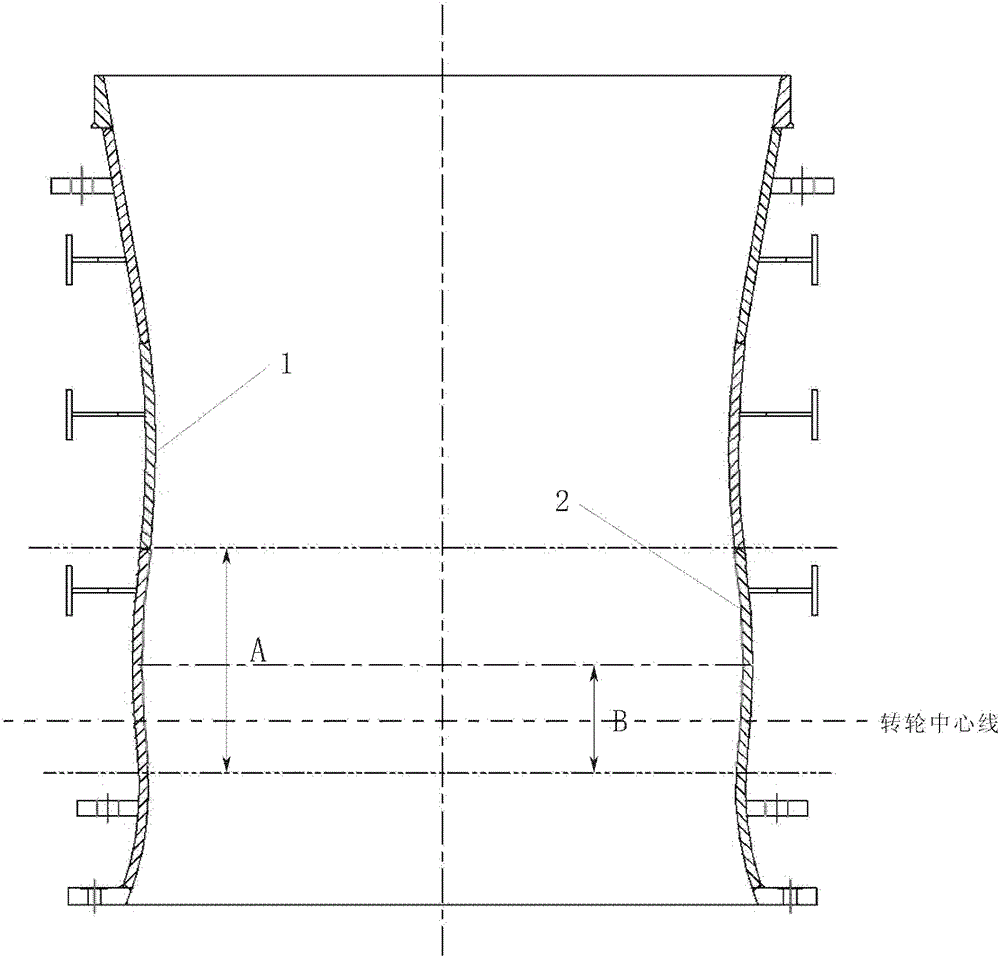

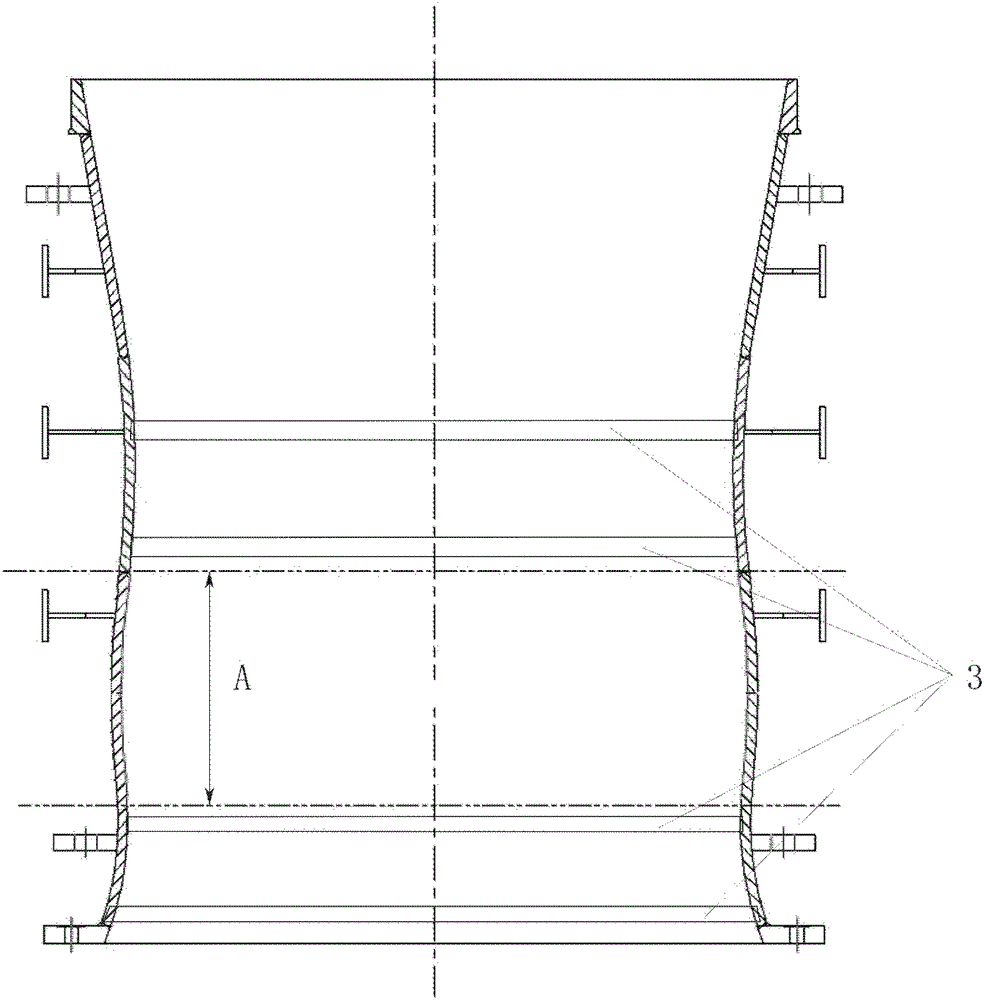

[0026] Such as figure 1 As shown, earlier power stations had lower requirements on the runner chamber. The spherical section 1 of the runner chamber was made of carbon steel, which had poor wear resistance, and the throat section 2 was made of stainless steel, which had better wear resistance. As the operating time of the unit increases, the cavitation erosion in the active area of the blade (that is, the spherical section) will gradually increase. In the figure, A is the distribution area of cavitation, and the most serious part of cavitation is area B near the centerline of the runner.

[0027] On-site repair of the cavitation area of the runner chamber, the steps are as follows:

[0028] First, pre-cleaning. First clean the rust, sand, oil and other dirt on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com