Comprehensive utilization method of low-grade magnesite

A magnesite, low-grade technology, applied in the direction of magnesium oxide, magnesium hydroxide, calcium carbonate/strontium/barium, etc., can solve the problems of complicated process, high cost, unusable acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

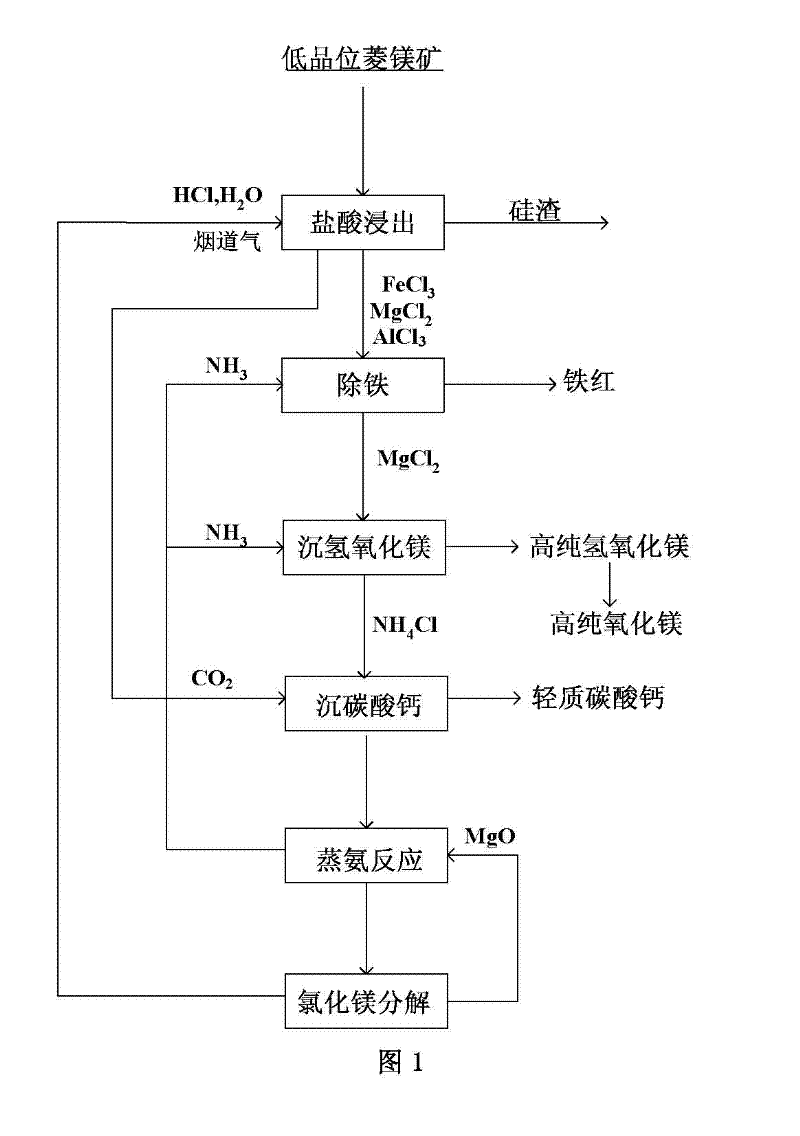

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the method for comprehensive utilization of this low-grade magnesite is carried out according to the following steps:

[0037] In the first step, first crush the magnesite to more than 45 meshes, and react with the high-temperature hydrochloric acid solution produced on site. Over hours, elements such as magnesium and iron form chlorides with chlorine;

[0038] In the second step, the magnesium oxide obtained in the first step is reacted with ammonia water with a concentration of 5 wt% to 10 wt%, the reaction temperature is 50°C to 80°C, air is introduced or hydrogen peroxide is added as an oxidant, and the hydrogen peroxide in the solution is The valence of iron becomes trivalent, and the pH is controlled at 7 to 8 to form iron red precipitate, which becomes iron red after drying, and the drying temperature is above 110°C to obtain iron red;

[0039] In the third step, the chloride obtained in the second step is neutralized with 10% to 20% ammoni...

Embodiment 2

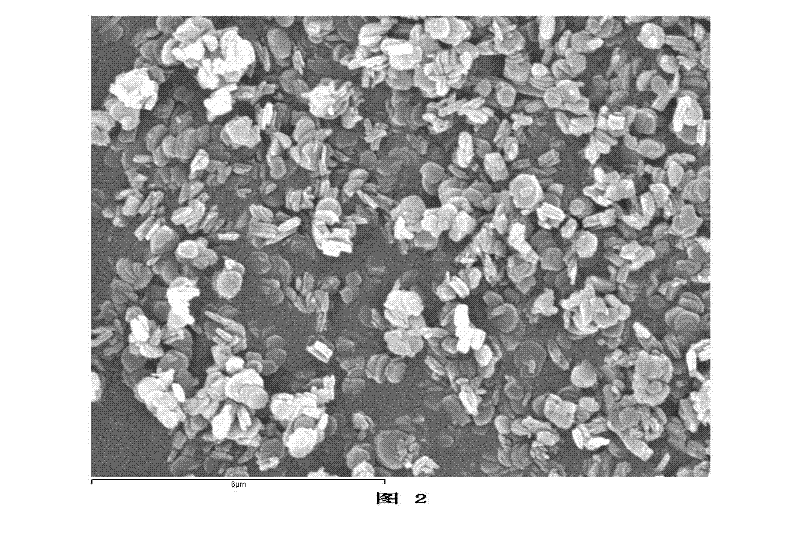

[0043] Embodiment 2, the method for comprehensive utilization of this low-grade magnesite is carried out according to the following steps: take 1 kg of Xinjiang Shanshan Jianshan magnesite, its main component includes MgCO 3 80.96%, Fe 2 O 3 0.53%, CaCO 3 7.78%、Al 2 O 3 1.62%, SiO 2 1.89%, weight loss at 800°C: 48.25%, mixed with the water vapor generated after the decomposition of magnesium chloride and the condensed liquid of the HCl mixture, and reacted in an enamel reactor, where the concentration of HCl is 15%, a total of 4500 ml, the reaction temperature 50°C, reaction time 1 hour, normal pressure. Filter after the reaction, put the filtrate into the reactor, add 20ml of hydrogen peroxide with a concentration of 30wt% to carry out the oxidation reaction, the reaction temperature is 80°C, then slowly add 5.6% ammonia solution to carry out the reaction of iron precipitation, the pH is controlled above 7, and then Stop the reaction, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com