Method for comprehensively utilizing asbestos tailings

A technology of asbestos tailings and filtrate, applied in the direction of magnesium oxide, magnesium hydroxide, iron oxide, etc., can solve the problems of high transportation cost, difficult control of magnesium hydroxide product quality, secondary pollution, etc., and achieve the effect of high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

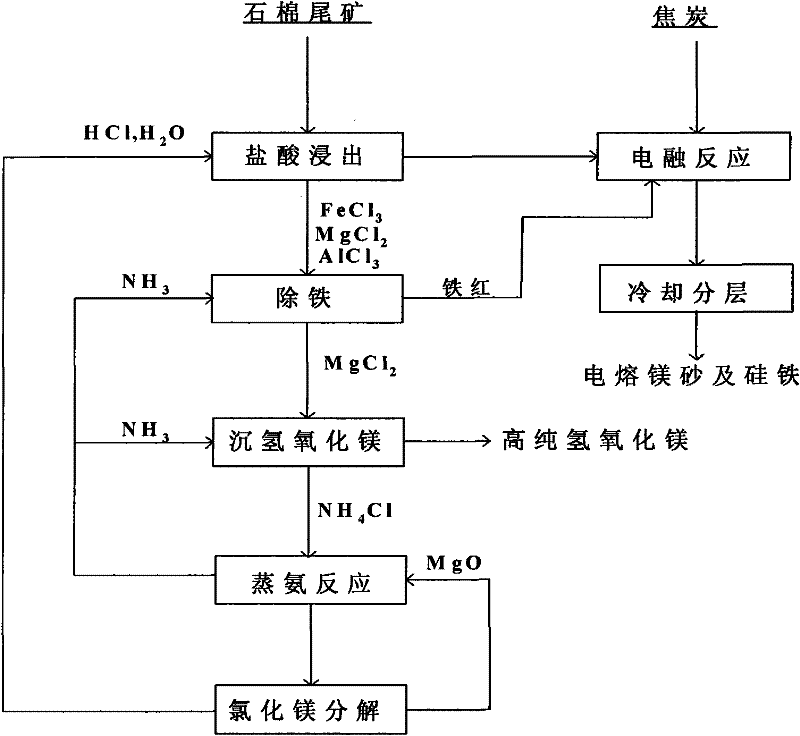

[0041] Embodiment 1, the method for comprehensive utilization of this cotton tailings is carried out according to the following steps:

[0042] In the first step, the asbestos tailings and hydrochloric acid are fully reacted at normal pressure at 80°C to 110°C, and then filtered to obtain acid leaching solution and acid leaching residue respectively;

[0043] In the second step, the pickling solution obtained in the first step is fully oxidized with an oxidizing agent so that the divalent iron in it becomes ferric iron, and then mixed with 5% to 10% ammonia water at normal pressure, 50°C to 90°C The reaction is carried out at ℃, and the reaction is stopped when the pH value reaches 7 to 8, and the solid iron red and the second-step filtrate are respectively obtained by filtration;

[0044] The third step is to fully react the above-mentioned second step filtrate with 10% to 20% ammonia water at normal pressure, 50°C to 90°C, and a pH value of 10 to 11, and then filter to obtai...

Embodiment 2

[0046] Embodiment 2, the method for the comprehensive utilization of this cotton tailings is carried out according to the following steps:

[0047] In the first step, the asbestos tailings and hydrochloric acid are fully reacted at normal pressure, 80°C or 110°C, and then filtered to obtain acid leaching solution and acid leaching residue respectively;

[0048] In the second step, the pickling solution obtained in the first step is fully oxidized with an oxidizing agent so that the divalent iron in it becomes ferric iron, and then mixed with 5% or 10% ammonia water at normal pressure, 50°C or 90°C. The reaction is carried out at ℃, and the reaction is stopped when the pH value reaches 7 or 8, and the solid iron red and the second-step filtrate are respectively obtained by filtration;

[0049] The third step, after fully reacting the above-mentioned second step filtrate with 10% or 20% ammonia water at normal pressure, 50°C or 90°C, and a pH value of 10 or 11, filter to obtain ...

Embodiment 3

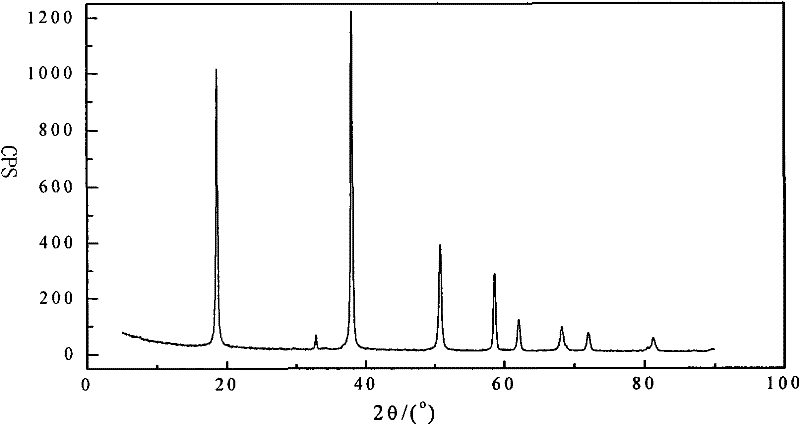

[0058] Embodiment 3, take the asbestos tailings of 1kg, its main component comprises SiO 2 41.22%, Al 2 o 3 0.10%, Fe 2 o 3 +FeO7.00%, CaO0.33%, MgO38.10%, K 2 O 0.04%, Na 2 O 0.22%, MnO 0.032%, weight loss at 800°C: 13.25%, mixed with the condensed liquid of the water vapor generated by the decomposition of magnesium chloride and the HCl mixture, and reacted in the enamel reactor, where the concentration of HCl is 15% or 22 % (or 15% to 22%), a total of 4500ml, a reaction temperature of 80°C or 110°C (or 80°C to 110°C), a reaction time of 1 hour or 2 hours (or 1 hour to 2 hours), normal pressure. Filter after the reaction, wash the filter cake, and dry to obtain high-silicon slag as a raw material for preparing fused magnesia; add the filtrate to the reactor, add 30ml of hydrogen peroxide with a concentration of 30% to carry out the oxidation reaction, and the reaction temperature is at 50°C or 90°C ℃ (or 50 ℃ to 90 ℃), then slowly add 5% to 10% (or 5% to 10%) ammonia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com