Water-based coating paint for food packaging paper and preparation method of water-based coating paint

A food packaging paper, water-based coating technology, applied in paper coatings, textiles, papermaking, papermaking, etc., can solve the problems of complex components of water-based coating coatings, residual organic monomers and additives, poisonous and harmful, etc. Difficulty in making pulp and recycling, improving film-forming effect, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

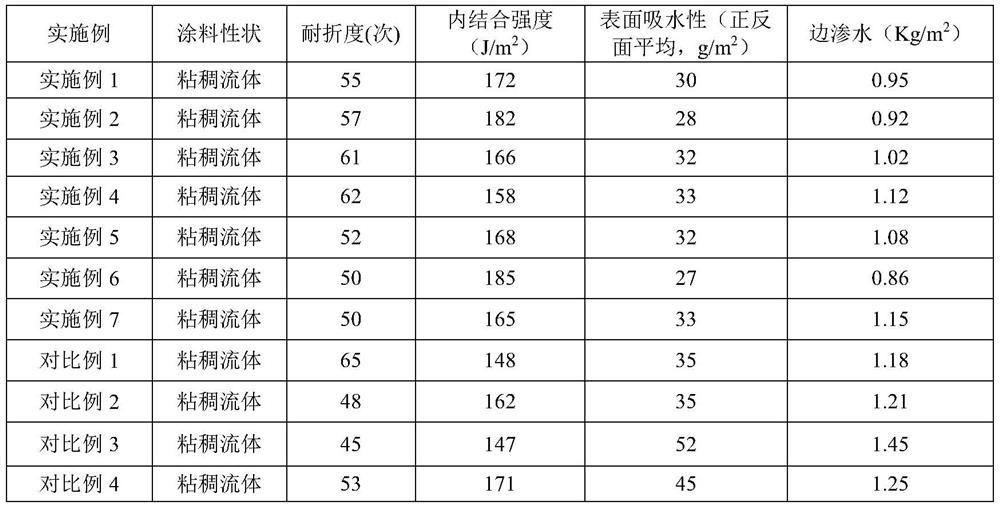

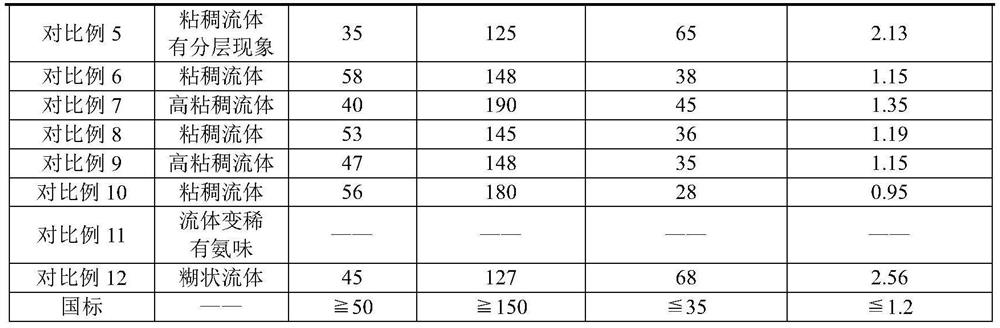

[0023] Example 1 Preparation of coating coating of the present invention

[0024] 6Kg of dialdehyde starch, 11Kg of soybean protein isolate powder and 200Kg of water were added to the reaction vessel and stirred to disperse to form a mixed material. Then, flaky sodium hydroxide was added to the mixture, the pH value of the mixture was adjusted to 9, and the gelatinization reaction was carried out by heating under stirring conditions. The gelatinization reaction temperature was 85° C. and the time was 45 minutes. After the gelatinization reaction is completed, the reaction material is cooled to normal temperature, silica sol, 10Kg of silica sol with a solid content of 20wt%, pH value of 7, 0.25Kg of coupling agent KH560, stirring and mixing evenly, that is, it can be used for food packaging Waterborne coating for paper production. This coating is used to coat processed food and beverage paper, and the performance index of the obtained processed paper is shown in Table 1.

Embodiment 2

[0025] Example 2 Preparation of coating coating of the present invention

[0026] 4Kg of dialdehyde starch, 13Kg of soybean protein isolate powder and 200Kg of water were added into the reaction vessel and stirred to disperse to form a mixed material. Then add 30wt% sodium hydroxide solution to the mixture, adjust the pH value of the mixture to 9, and heat under stirring for gelatinization reaction, the gelatinization reaction temperature is 85°C, and the time is 45 minutes. After the gelatinization reaction is over, the material obtained from the reaction is cooled to room temperature, silica sol is added with 8Kg of silica sol with a solid content of 20wt%, pH value is 7, 0.25Kg of coupling agent KH560, stirred and mixed evenly, and it can be used for food packaging. Waterborne coating for paper production. This coating is used to process food and beverage paper, and the performance indexes of the obtained processed paper are shown in Table 1.

Embodiment 3

[0027] Example 3 Preparation of coating coating of the present invention

[0028] 3Kg of dialdehyde starch, 12Kg of soybean protein isolate powder and 200Kg of water were added to the reaction vessel and stirred to disperse to form a mixed material. Then, flaky sodium hydroxide was added to the mixture, the pH value of the mixture was adjusted to 9, and the gelatinization reaction was carried out by heating under stirring conditions. The gelatinization reaction temperature was 90° C. and the time was 30 minutes. After the gelatinization reaction is completed, the material obtained from the reaction is cooled to room temperature, silica sol, 8Kg of silica sol with a solid content of 20wt%, pH value of 7, and 0.2Kg of coupling agent KH560 are added, stirred and mixed evenly, that is, it can be used for food packaging Waterborne coating for paper production. This coating is used to process food and beverage paper, and the performance indexes of the obtained processed paper are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com