A method of sewage treatment using km biological contact oxidation process

An oxidation process and sewage treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor removal of ammonia nitrogen, etc. Stable, simple maintenance and management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

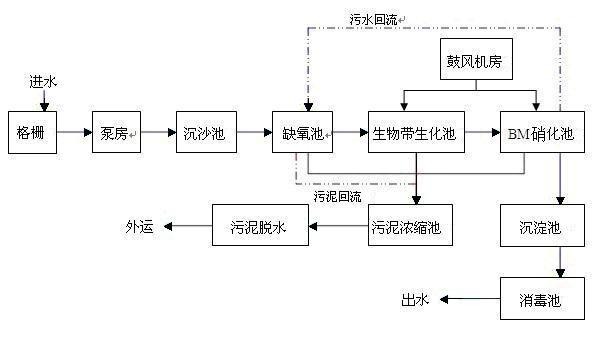

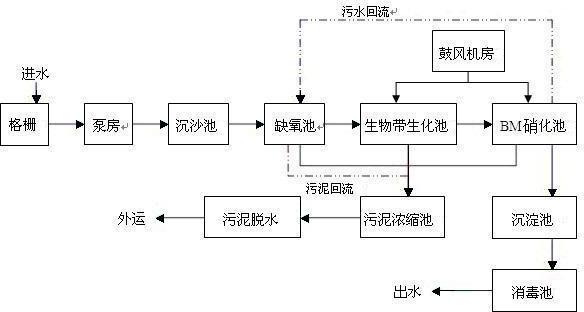

[0033] Such as figure 1 As shown, the present embodiment provides a method for sewage treatment using the KM biological contact oxidation process, the method includes the following steps in turn:

[0034] (1) Sewage enters the grid to remove large-sized floating matter, suspended matter and small solid matter, such as branches, leaves, discarded clothes, discarded plastic bags and solid organic matter, etc.;

[0035] (2) Lift the sewage to the subsequent treatment structure through the lifting pump;

[0036] (3) Remove dense inorganic particles, such as sand, through the grit chamber;

[0037] (4) Enter the anoxic pool, adjust the water quality, and carry out the denitrification process;

[0038] (5) Enter the biological belt biochemical pool, in which the biological belt is arranged, high-efficiency composite bacteria are added, supplemented by micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com