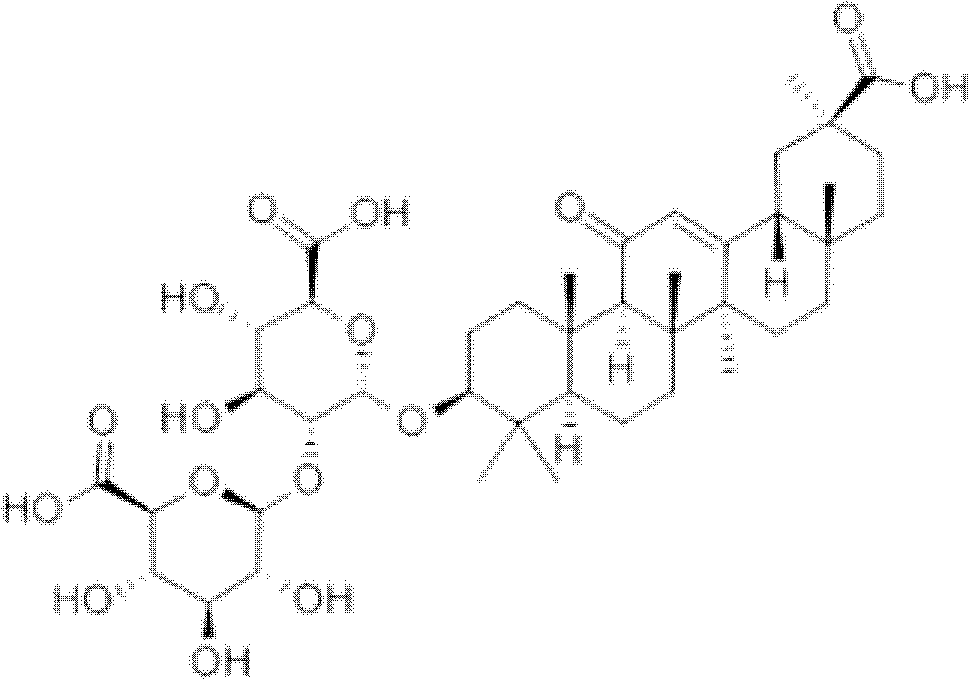

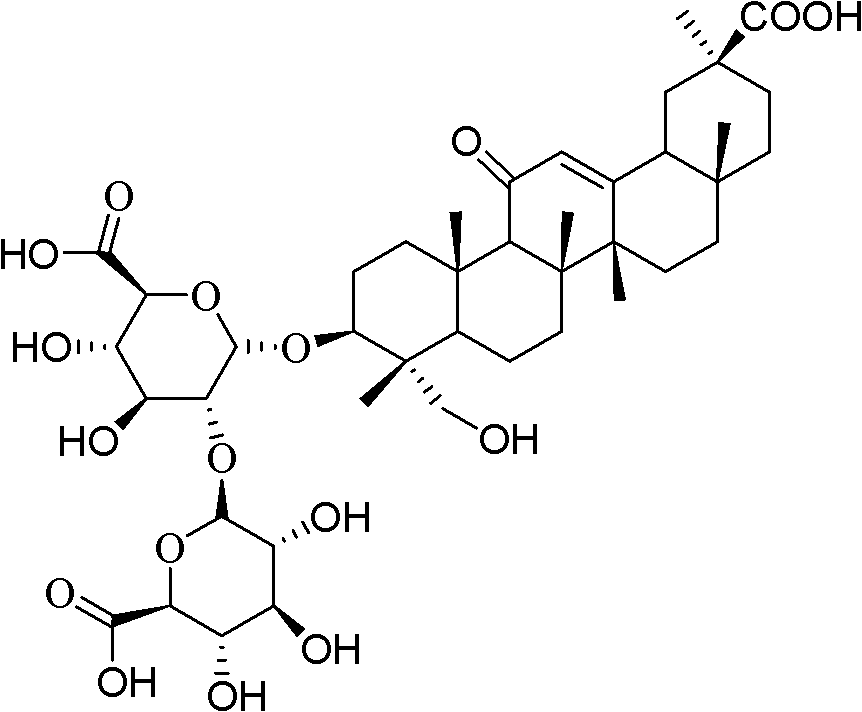

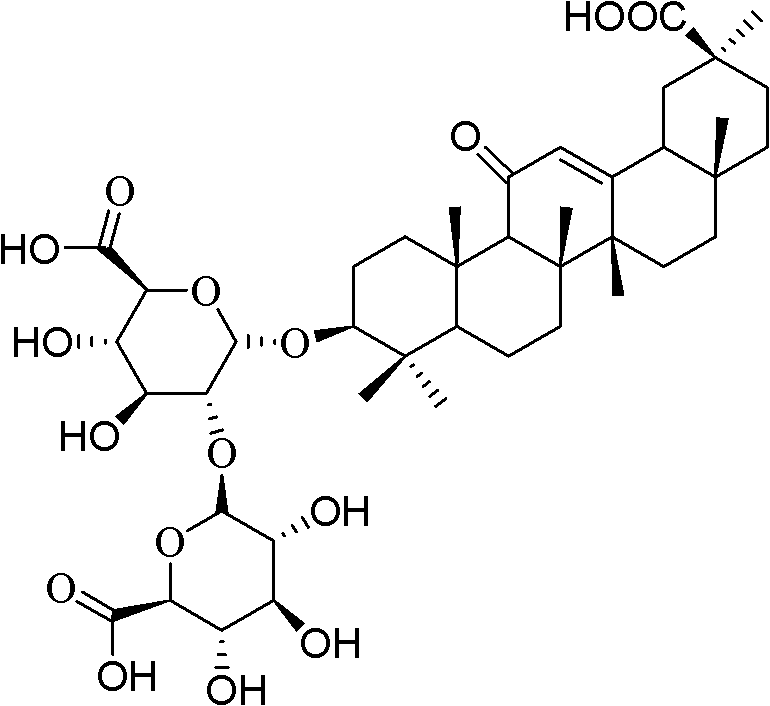

A method for preparing high-purity glycyrrhizic acid

A high-purity glycyrrhizic acid technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, steroids, etc., can solve the problems of difficulty in obtaining high purity and low efficiency of glycyrrhizic acid, and achieve low cost and high product purity , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of Monoammonium Glycyrrhizinate

[0029] Dissolve 100.0 g of crude product with a glycyrrhizic acid content of 10% in 700 ml of water, add dilute sulfuric acid under stirring to adjust its pH to 2.0, filter, and dry at room temperature to obtain crude glycyrrhizic acid. Add 6 times the amount of acetone to the crude glycyrrhizic acid and reflux for leaching for 2 hours, pass ammonia gas into the leaching solution to make the pH value 8.0-9.0, make it react to form triammonium glycyrrhizinate, filter, add to the precipitate 6 times the amount of glacial acetic acid to obtain the crude product of monoammonium glycyrrhizinate. The monoammonium glycyrrhizinate crude product is recrystallized, the solvent ratio is chloroform: ethanol: water = 1: 5: 5, the solid-liquid ratio is 1: 2, and the dissolution temperature is 70 ° C. After the temperature drops to room temperature, place it in an ice-water bath After 3 hours, filter, dry the crystalline product at 60°...

Embodiment 2

[0041] 1. Preparation of Monoammonium Glycyrrhizinate

[0042] Dissolve 100.0 g of the crude product with a glycyrrhizic acid content of 10% in 700 ml of water, add dilute sulfuric acid under stirring to adjust the pH to 3.0, filter, and dry at room temperature to obtain the crude glycyrrhizic acid. Add 6 times the amount of acetone to the crude glycyrrhizic acid and reflux for leaching for 2 hours, pass ammonia gas into the leaching solution to make the pH value 8.0-9.0, make it react to form triammonium glycyrrhizinate, filter, add to the precipitate 6 times the amount of glacial acetic acid to obtain the crude product of monoammonium glycyrrhizinate. The crude product of monoammonium glycyrrhizinate salt is recrystallized, the solvent ratio is chloroform: ethanol: water = 1: 4: 4, the solid-liquid ratio is 1: 2, and the dissolution temperature is 70 ° C. After the temperature drops to room temperature, place it in an ice-water bath After 4 hours, filter, dry the crystalliz...

Embodiment 3

[0052] 1. Preparation of Monoammonium Glycyrrhizinate

[0053] Dissolve 100.0 g of the crude product with a glycyrrhizic acid content of 10% in 700 ml of water, add dilute sulfuric acid under stirring to adjust its pH to 4.0, filter, and dry at room temperature to obtain crude glycyrrhizic acid. Add 6 times the amount of acetone to the crude glycyrrhizic acid and reflux for leaching for 2 hours, pass ammonia gas into the leaching solution to make the pH value 8.0-9.0, make it react to form triammonium glycyrrhizinate, filter, add to the precipitate 7 times the amount of glacial acetic acid to obtain the crude product of monoammonium glycyrrhizinate. The monoammonium glycyrrhizinate crude product is recrystallized, the solvent ratio is chloroform: ethanol: water = 1: 3: 3, the solid-liquid ratio is 1: 2, and the dissolution temperature is 70 ° C. After the temperature drops to room temperature, place it in an ice-water bath After 3 hours, filter, dry the crystalline product at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com