A kind of antibacterial polypropylene foam plastics and preparation method thereof

A technology of antibacterial polypropylene and foam plastics, applied in the field of antibacterial plastics, can solve the problems of easy precipitation, poor heat resistance of antibacterial plastic products, easy discoloration of antibacterial plastic products and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] One, the preparation of compound antibacterial agent

[0050] 1. Composite antibacterial agent 1: polyhexamethylene guanidine propionate / polyzinc silicate composite antibacterial agent

[0051] (1) Weigh 100.0 g (0.465 mol) of polyhexamethylene guanidine propionate (Shanghai Gaoju F3000), add it to 300 mL deionized water solution, stir to dissolve it, and call it solution A; (2) also call it Add 70.0g (0.246mol) of sodium silicate (chemically pure) into 300mL of deionized water, stir to dissolve, and call it solution B; (3) mix solution A and solution B at room temperature (about 25°C) , and fully stirred for 30 minutes to form solution C; (4) Weigh zinc sulfate ZnSO 4 (Chemically pure) 180.0g (0.626mol), slowly poured into solution C, and vigorously stirred for 5min, the precipitate was filtered, dried, and pulverized to obtain polyhexamethylene guanidine propionate / polysilicate zinc composite antibacterial agent; wherein the molar ratio of polyhexamethylene guanidin...

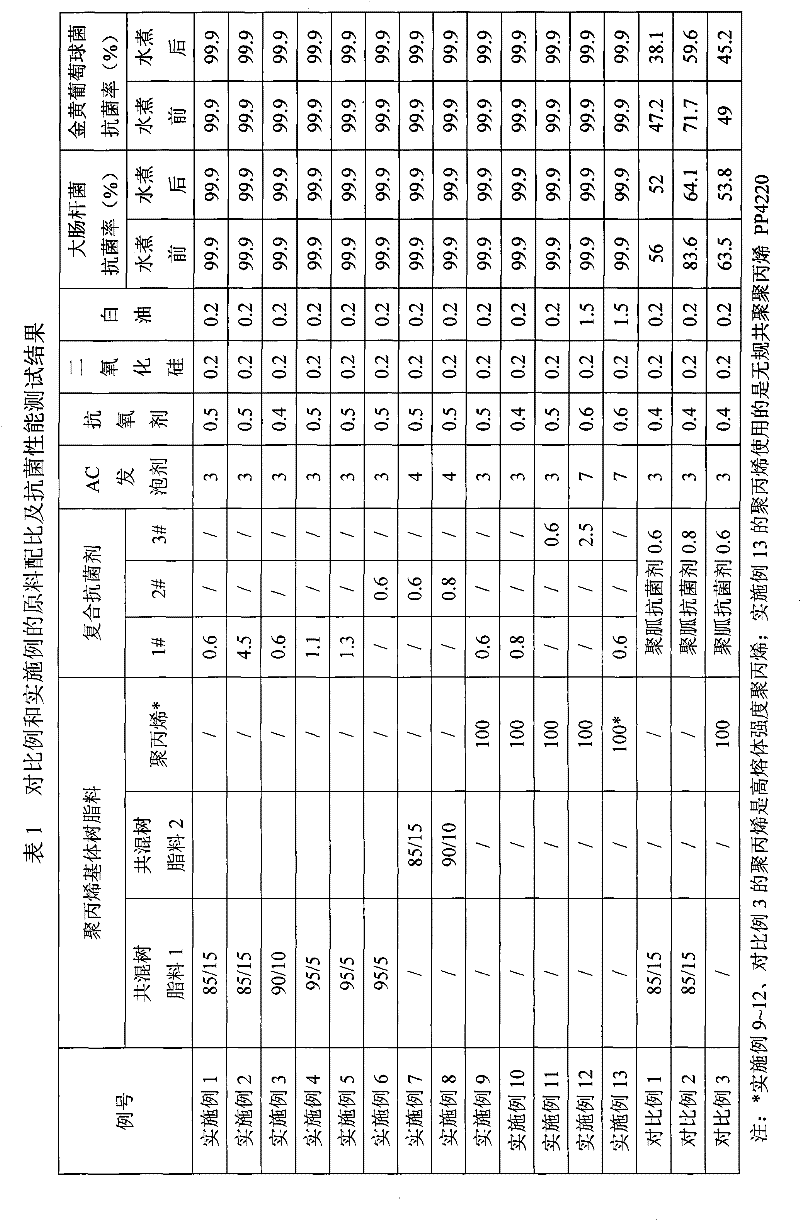

Embodiment 1~13

[0057] Put matrix resin (polypropylene blended resin material, or high melt strength polypropylene), compound antibacterial agent, AC foaming agent, antioxidant 1010, antioxidant 168, silicon dioxide, white oil into a high-speed mixer , stir at high speed until evenly mixed, and discharge after 1 to 3 minutes. Use a double-roller masticator to masticate the mixed materials. The mastication temperature is 175°C to 185°C. Thin pass for 5 to 10 minutes, and then the sheet is released. Then use a molding foaming machine to mold and foam to form a 3mm thick sheet. The foaming temperature is 230°C, cut into the required sample size, and carry out the antibacterial performance test.

[0058] The above materials are all based on 100 parts by weight of polypropylene matrix resin, antioxidant 1010 and antioxidant 168 are compounded, and the weight ratio is 1:1. The specific formulations of other components are shown in Table 1. The antibacterial performance test results before and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com