A method for nitrogen fixation using organic wastewater for anaerobic fermentation of straw

An organic waste water and anaerobic fermentation technology, applied in the field of comprehensive utilization of resources, can solve the problems of insufficient nitrogen source, unable to ferment gas production normally, waste of resources, etc., and achieve the effects of simple process, avoiding pollution and damage, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The test uses the waste water produced by the malt sugar factory as a sample, part of which is used as a nutrient substrate for photosynthetic bacteria after being sterilized by ultraviolet light, and part of which is used as an air deoxygenation medium.

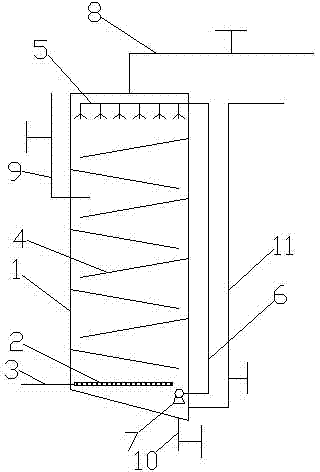

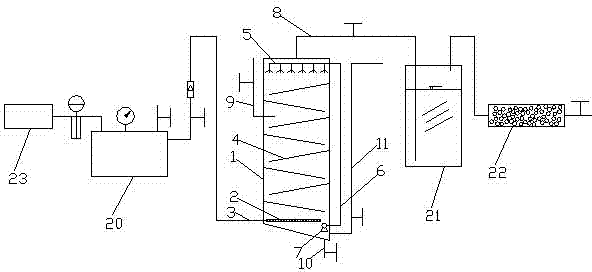

[0018] Deoxygenation reactors, such as figure 1 As shown, it includes a shell 1, the bottom of the shell 1 is provided with an aerator 2, the inlet of the aerator 2 is connected to the air intake pipe 3, and the inner wall of the shell 1 above the aerator 2 is vertically spaced and staggered. Inclined and upwardly inclined baffles 4, there is a gap between the far end of the baffles 4 and the inner wall of the opposite housing 1; the top of the housing 1 is provided with a shower 5, and the inlet of the shower 5 passes through the circulation pipe 6 It is connected to the bottom of the housing 1, and the inlet of the circulation pipe 6 is provided with a circulation pump 7. During operation, the circulation pump 7 cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com