±1120kv DC Rod Porcelain Insulator

A technology of porcelain insulators and insulators, applied in the field of DC rod-shaped porcelain insulators, can solve the problems of low torsional strength of composite insulators, incomplete production process, aging and deterioration of composite insulators, etc. Effect of steep wave impact damage and interface aging, high internal insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: This embodiment is a pillar DC rod-shaped porcelain insulator.

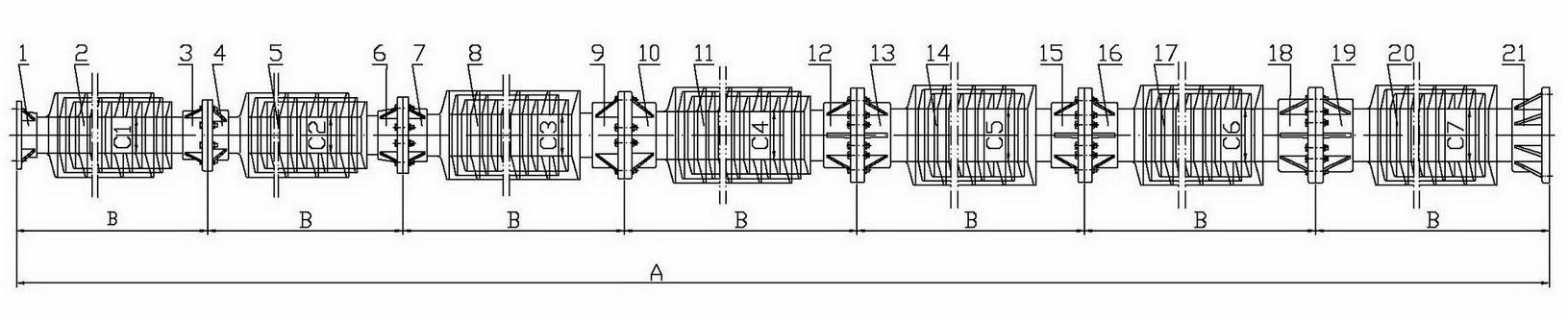

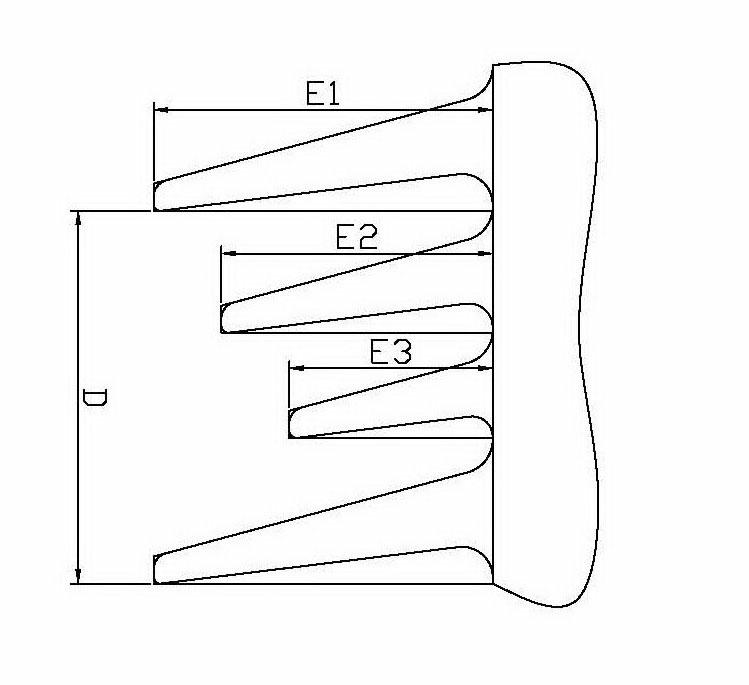

[0015] Such as figure 1 As shown in , the DC rod-shaped porcelain insulator is composed of 7 sections of porcelain elements of equal height, and the porcelain elements are fastened and connected by flanges. The length B of each porcelain element is 2100mm, and the total length A of the insulator is 14700mm. Among them: from left to right, the first section of porcelain components is made of porcelain part 2 and upper and lower flanges 1 and 3 through cement glue. The main body diameter C1 of porcelain part 2 is φ165-φ195mm, and φ185mm is selected for both. The maximum umbrella diameter is φ385mm; the second section of the porcelain component is made of porcelain part 5 and upper and lower flanges 4 and 6 through cement glue. Umbrella diameter is φ390mm; the porcelain element in Section 3 is made of porcelain part 8 and upper and lower flanges 7 and 9 glued together by cement glue. The diam...

Embodiment 2

[0030] Embodiment 2: This embodiment is to operate a DC rod-shaped porcelain insulator.

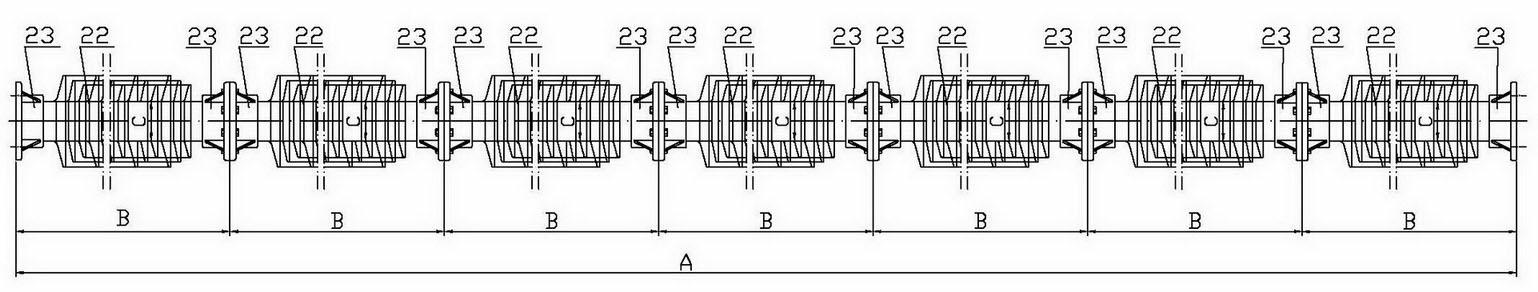

[0031] Such as image 3 As shown, the DC rod-shaped porcelain insulator is composed of 7 sections of porcelain elements of equal height, and the porcelain elements are tightly connected by flanges. The length B of each porcelain element is 2100mm, and the total length A of the insulator is 14700mm. Every section of porcelain element is made of porcelain parts 22 and upper and lower flanges 23 by cement glue. The main body diameter C of porcelain parts 22 is φ180-φ200mm, all selects φ190mm, and the maximum umbrella diameter is φ390mm. All the above flanges are made of QT450-10 material. The above-mentioned flange installation hole center distance - hole number - hole diameter is: φ300-8-φ18. The umbrella shape of the above-mentioned porcelain components adopts a pollution-resistant light umbrella structure with one large umbrella, one middle umbrella and one small umbrella, and no edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com