A chemical fiber oil bactericidal preservative and preparation method thereof

A technology of bactericidal preservatives, chemical fiber oil, applied in the directions of fungicides, botanical equipment and methods, biocides, etc., can solve the problem of inconvenient production and use of chemical fiber oil, poor compatibility of chemical fiber oil, poor social and economic benefits and other problems, to achieve significant social and economic benefits, low production costs, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

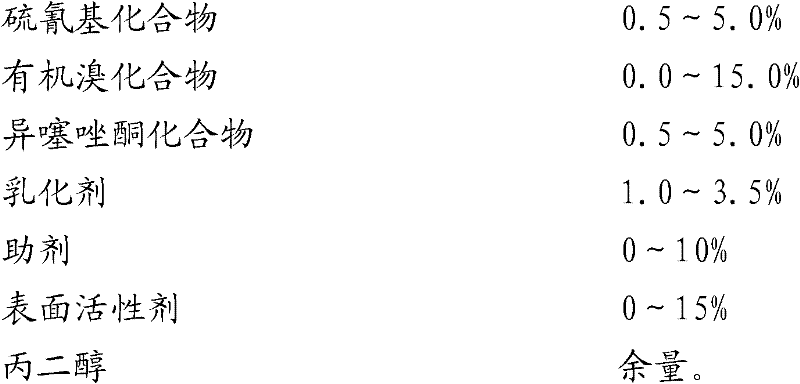

[0021] A bactericidal and antiseptic agent for chemical fiber oil, which is composed of bactericidal and antiseptic active ingredients such as sulfur cyano compounds, organic bromine compounds, and isothiazolone compounds, assistants, emulsifiers, surfactants, and a balanced amount of propylene glycol. The weight percentage of this preparation is:

[0022]

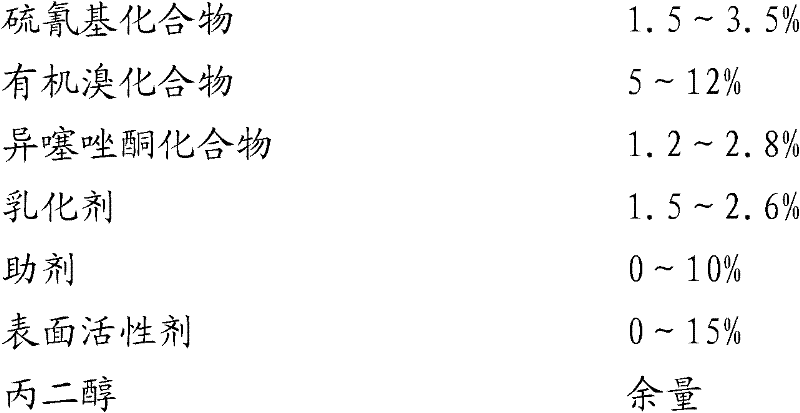

[0023] The preferred percentage by weight of the preparation is:

[0024]

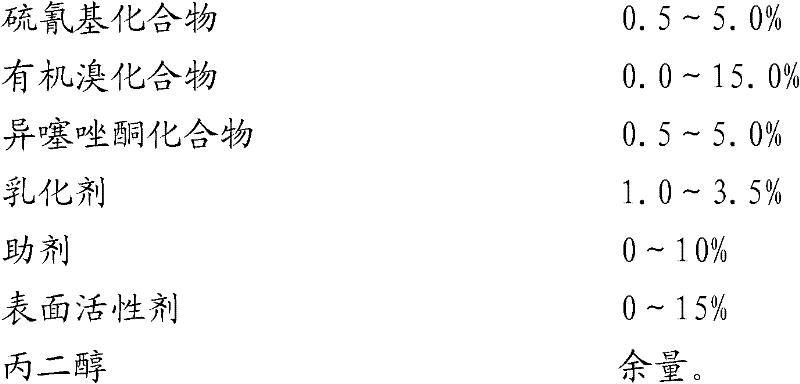

[0025]

[0026] Wherein, the thiocyanate compound is thiocyanate or dithiocyanomethane; the organic bromine compound is dibromonitroethanol, bronopol or dibromocyanopropionamide; the isothiazolone is benzene Paraisothiazolinone, Octylisothiazolinone, Cathone or Dichlorooctylisothiazolinone.

[0027] The preparation method of the above-mentioned chemical fiber oil agent bactericidal preservative is: by preparing the thiocyanate compound, the organic bromine compound and the isothiazolone compound respectively at normal pressure and normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com