Oral cleaning and mouthwash preparation method

A technology for oral cleaning and manufacturing methods, which is applied in oral care, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of high cost of raw materials and complicated preparation methods, and achieve low raw material prices, comfortable taste, and simple and easy manufacturing processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

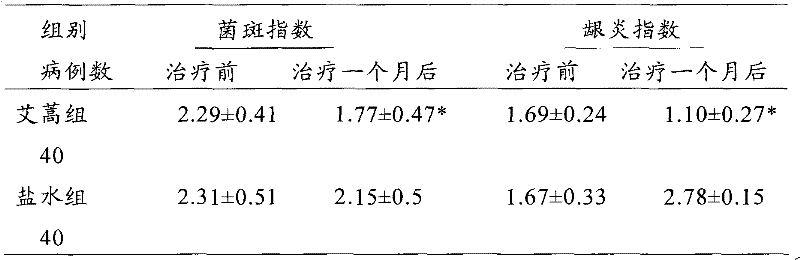

Image

Examples

Embodiment 1

[0024] a. Take fresh mugwort leaves, wash them and dry them in the shade indoors for 3-4 days. The water content of mugwort leaves is 8%. Weigh 100 grams of dried mugwort leaves and put them in a heating vessel, add 50 times of pure water 5000ml , boiled for 25 minutes, cooled to room temperature and filtered to obtain the filtrate. The mugwort extract that filtrate is concentrated to 1 / 20 of the original volume is standby;

[0025] b. Weigh 30 grams of glycerin, 3 grams of peppermint essential oil, 2 grams of sodium saccharin, 2.5 grams of Tween 80, 140 grams of 95% (v / v) edible alcohol, mix well, add 200 grams of mugwort concentrate, and add the remainder Water to 1000g, mix and let stand for 12 hours, membrane filter and pack to be the finished product.

Embodiment 2

[0027] a. Take fresh mugwort leaves, wash them and dry them in the shade indoors for 3-4 days. When the mugwort leaves are crushed by hand, the water content of the mugwort leaves is 5%. Weigh 100 grams of dried mugwort leaves and put them in a heating vessel In, add 5000 ml of pure water, boil for 20 minutes, cool to room temperature and filter to obtain the filtrate. Concentrate the filtrate to 1 / 10 and put it in a beaker for later use;

[0028] b. Weigh 10 grams of glycerin, 1 gram of peppermint essential oil, 1 gram of sodium saccharin, 1 gram of Tween 80, 40 grams of 95% (v / v) edible alcohol, mix well, add 100 grams of mugwort concentrate, and add the remainder Water to 1000g, mix and let stand for 20 hours, membrane filter and pack to be the finished product.

Embodiment 3

[0030] a. Take fresh mugwort leaves, wash them and dry them in the shade indoors for 3-4 days. When the mugwort leaves are crushed by hand, the water content of the mugwort leaves is 10%. Weigh 100 grams of dried mugwort leaves and put them into a beaker , add 5000 ml of purified water, boil for 30 minutes, cool to room temperature and filter to obtain the filtrate. Concentrate the filtrate to 1 / 20 and put it in a beaker for later use;

[0031] b. Take by weighing 50 grams of glycerin, 5 grams of peppermint essential oil, 3 grams of sodium saccharin, 4 grams of Tween 80, 240 grams of 95% (v / v) edible alcohol, mix well, add 300 grams of mugwort concentrate, and add the remainder Water to 1000 grams, mixed and left to stand for 24 hours, membrane filtered and packaged to be the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com