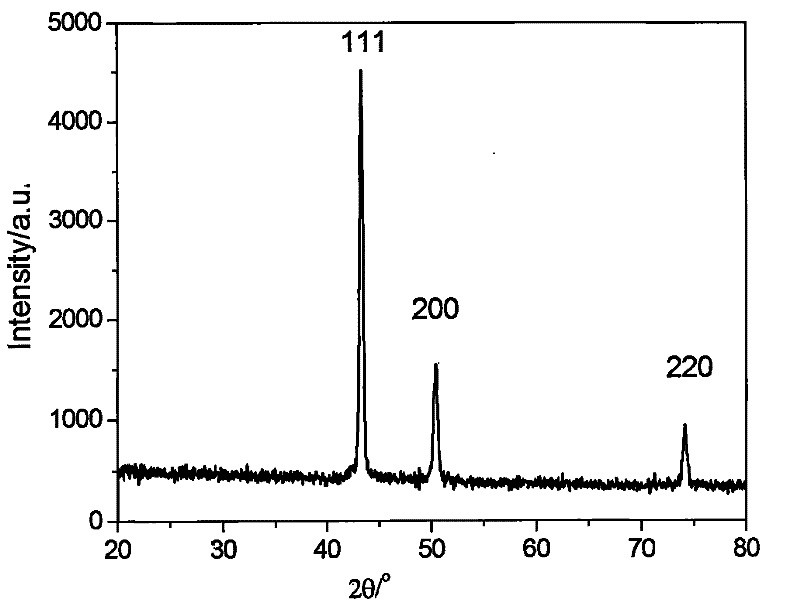

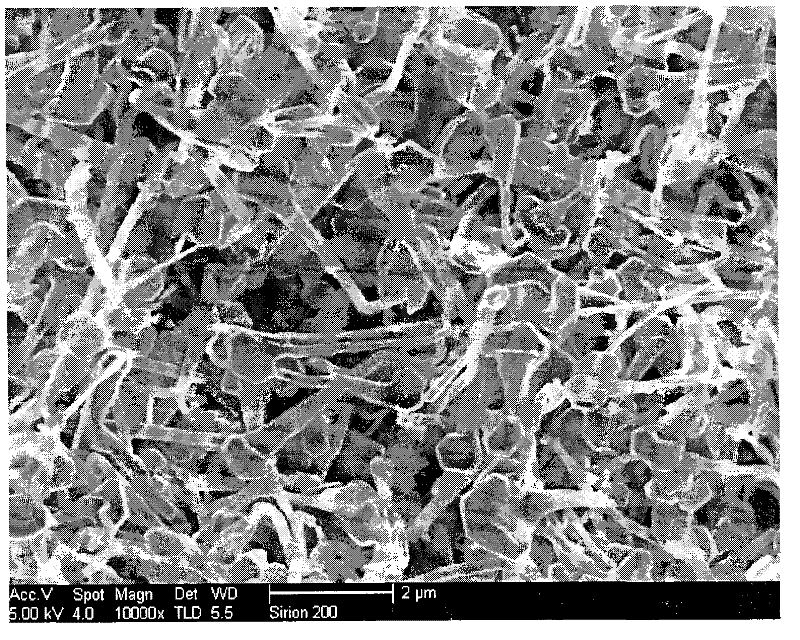

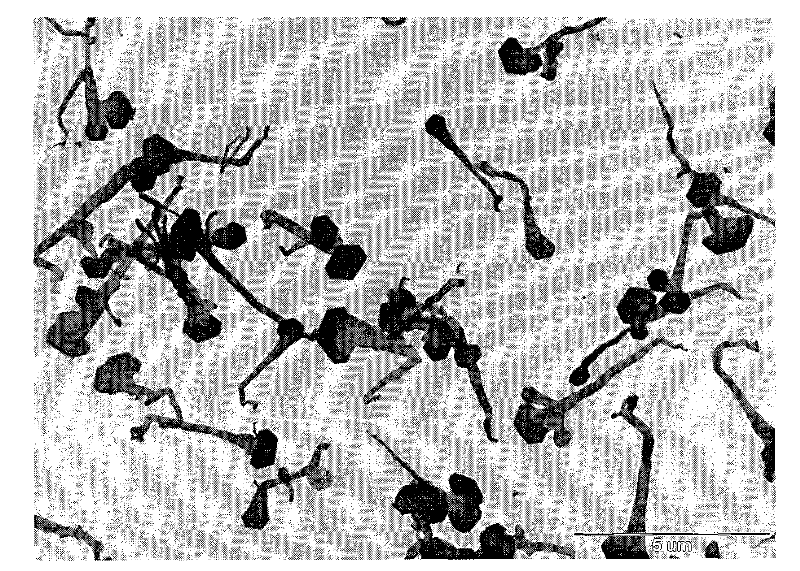

A kind of " tadpole " shape metal copper nano material and preparation method thereof

A technology of nanomaterials and metallic copper, which is applied in the field of "tadpole" metallic copper nanomaterials and its preparation, can solve problems such as "tadpole" metallic copper nanostructures that have not been seen, and achieve easy operation, easy realization, and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The "tadpole" metallic copper nanomaterial of the present invention is prepared by a microwave-assisted liquid phase reduction method, that is, soluble copper salt, hexamethylenetetramine and ascorbic acid are used as raw materials, water is used as a solvent, and the reaction mixture is heated in a household microwave oven It is formed by microwave irradiation reduction reaction process. Its specific technological process is as follows:

[0028] (1) Weigh 0.1596 grams of anhydrous copper sulfate and 0.348 grams of ascorbic acid into a 100 milliliter tall flask, add 30 milliliters of deionized water, stir and dissolve to obtain solution A;

[0029] (2) Weigh 4.48 g of hexamethylenetetramine into a 50 ml beaker, add 30 ml of deionized water, stir and dissolve to obtain solution B;

[0030] (3) Add solution B to solution A, cover with polyethylene film, and continue to stir the reaction mixture for 10 to 20 minutes;

[0031] (4) Place the reaction mixture in a microwave...

Embodiment 2

[0039] The "tadpole" metallic copper nanomaterial of the present invention is prepared by a microwave-assisted liquid phase reduction method, that is, soluble copper salt, hexamethylenetetramine and ascorbic acid are used as raw materials, water is used as a solvent, and the reaction mixture is heated in a household microwave oven It is formed by microwave irradiation reduction reaction process. Its specific technological process is as follows:

[0040] (1) Weigh 0.1594 grams of anhydrous copper sulfate and 0.346 grams of ascorbic acid into a 100 milliliter tall flask, add 30 milliliters of deionized water, stir and dissolve to obtain solution A;

[0041] (2) Weigh 3.36 g of hexamethylenetetramine into a 50 ml beaker, add 30 ml of deionized water, stir and dissolve to obtain solution B;

[0042] (3) Add solution B to solution A, cover with polyethylene film, and continue to stir the reaction mixture for 10 to 20 minutes;

[0043] (4) Place the reaction mixture in a microwave...

Embodiment 3

[0048] The "tadpole" metallic copper nanomaterial of the present invention is prepared by a microwave-assisted liquid phase reduction method, that is, soluble copper salt, hexamethylenetetramine and ascorbic acid are used as raw materials, water is used as a solvent, and the reaction mixture is heated in a household microwave oven It is formed by microwave irradiation reduction reaction process. Its specific technological process is as follows:

[0049](1) Weigh 0.1597 grams of anhydrous copper sulfate and 0.349 grams of ascorbic acid into a 100 milliliter tall flask, add 30 milliliters of deionized water, stir and dissolve to obtain solution A;

[0050] (2) Weigh 5.04 g of hexamethylenetetramine into a 50 ml beaker, add 30 ml of deionized water, stir and dissolve to obtain solution B;

[0051] (3) Add solution B to solution A, cover with polyethylene film, and continue to stir the reaction mixture for 10 to 20 minutes;

[0052] (4) Place the reaction mixture in a microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com