Amino resin with polyhydroxy structure and preparation method thereof

A kind of amino resin, polyhydroxyl technology, applied in the field of amino resin and its preparation, can solve the problem of limitation, no hydroxyl or amino group and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Synthesis of Ethylene Glycol Etherified Polyhydroxy Amino Resin

[0032] 1. Product Description

[0033] Product Name: Ethylene Glycol Etherified Polyhydroxyl Amino Resin

[0034] Molecular weight: 570.11

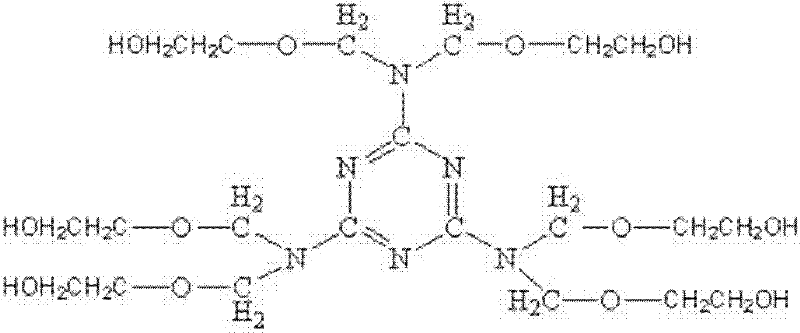

[0035] Molecular Structure:

[0036]

[0037] Quality Index

[0038] Appearance: light yellow transparent viscous liquid

[0039] Acid value: (mgKOH / g) ≤0.02

[0040] Chromaticity: (APHA) ≤35

[0041] Ignition point: ℃ ------

[0042] Specific gravity: (20 / 25°C) 1.017-1.023

[0043] Moisture:% ≤0.1

[0044] Physical and chemical properties: light yellow transparent viscous liquid; viscosity: 12000mPa.S / 25°C; refractive index: n25 = 1.432-1.438; solubility in water at 20°C: miscible; Alcohol, phosphate ester and other solvents.

[0045] Uses: Reactive polyurethane resin flame retardant. Flame retardant polyether starter.

[0046] 2. Synthesis technology

[0047] 1. Raw material ratio

[0048]

[0049]

[0050] 2. Synthesis process

[0051] 1) H...

Embodiment 2

[0067] Synthesis of Propylene Glycol Etherified Polyhydroxyl Amino Resin

[0068] 1. Product Description

[0069] Product Name: Propylene Glycol Etherified Polyhydroxy Amino Resin

[0070] Molecular weight: 654.16

[0071] Molecular Structure:

[0072]

[0073] Quality Index:

[0074] Appearance: light yellow transparent viscous liquid

[0075] Acid value: (mgKOH / g) ≤0.02

[0076] Chromaticity: (APHA) ≤35

[0077] Ignition point: ℃ ------

[0078] Specific gravity: (20 / 25°C) 1.011-1.017

[0079] Moisture:% ≤0.1

[0080] Physical and chemical properties: pale yellow transparent viscous liquid; solubility in water at 20°C: mutual solubility; specific gravity: (20 / 25°C): 1.011-1.017; soluble in alcohol, phosphate ester and other solvents.

[0081] Uses: Reactive polyurethane resin flame retardant. Flame retardant polyether starter.

[0082] 2. Synthesis technology

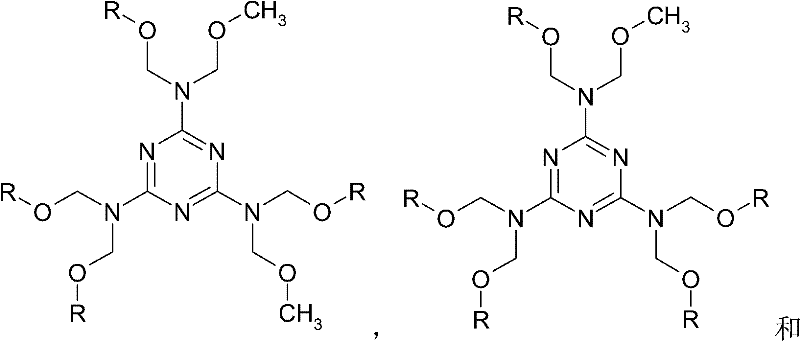

[0083] Synthesis of Methylated Amino Resin

[0084] 1. Raw material ratio

[0085]

[0086] 2. Sy...

Embodiment 3

[0103] Synthesis of Diethylene Glycol Etherified Polyhydroxyl Amino Resin

[0104] 1. Product Description

[0105] Product name: Diethylene glycol etherified polyhydroxy amino resin

[0106] Molecular weight: 834.28

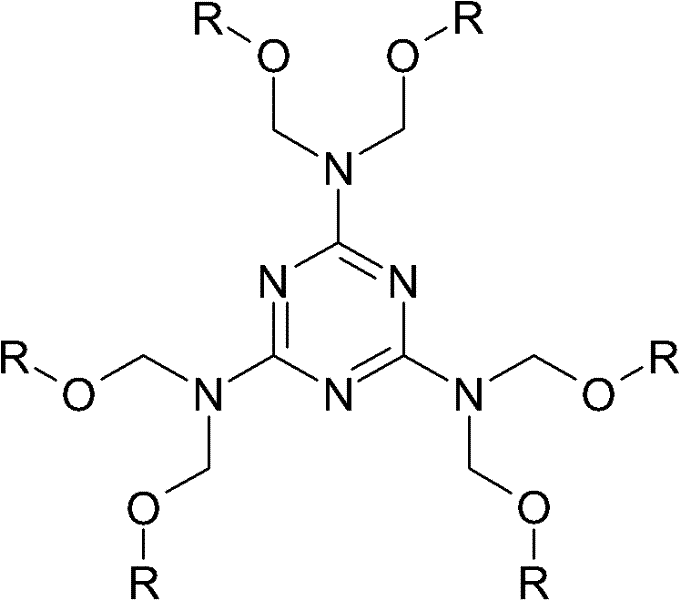

[0107] Molecular Structure:

[0108]

[0109] Quality Index:

[0110] Appearance: light yellow transparent viscous liquid

[0111] Acid value: (mgKOH / g) ≤0.02

[0112] Chromaticity: (APHA) ≤35

[0113] Ignition point: ℃ ------

[0114] Specific gravity: (20 / 25°C) 1.016-1.022

[0115] Moisture:% ≤0.1

[0116] Physical and chemical properties: light yellow transparent viscous liquid; solubility in water at 20°C: miscible; specific gravity: (20 / 25°C): 1.016-1.022; soluble in alcohol, phosphate ester and other solvents.

[0117] Uses: Reactive polyurethane resin flame retardant. Flame retardant polyether starter.

[0118] 2. Synthesis technology

[0119] Synthesis of Methylated Amino Resin

[0120] 1. Raw material ratio

[0121]

[0122] 2. Synthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com