A photobioreactor system for large-scale cultivation of oil-producing microalgae

A technology of photobioreactor and oil-producing microalgae, which is applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc. Problems such as high-cost high-density cultivation, high cultivation cost, and difficulty in series connection of reactors are achieved to achieve low-cost high-density cultivation, solve serious light attenuation, and achieve high-density cultivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

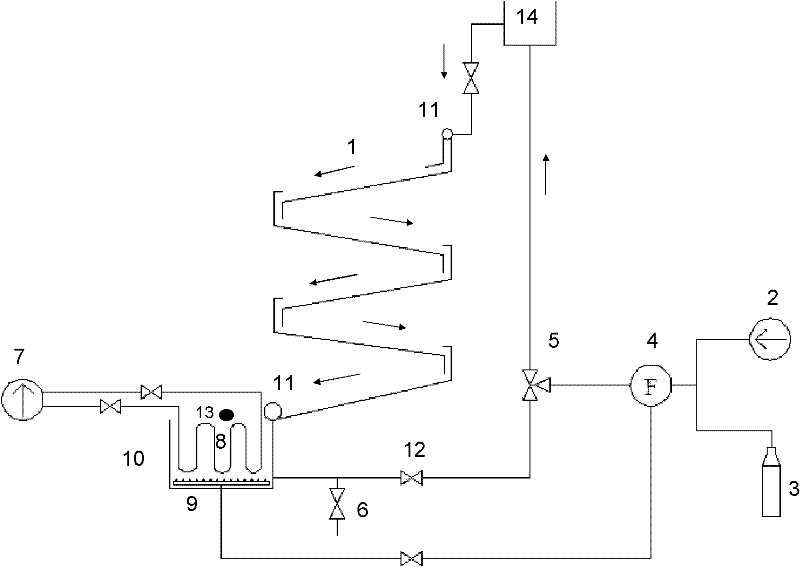

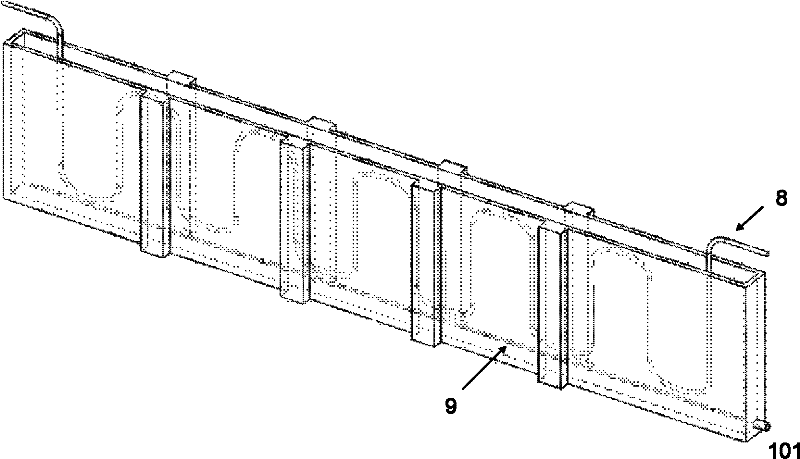

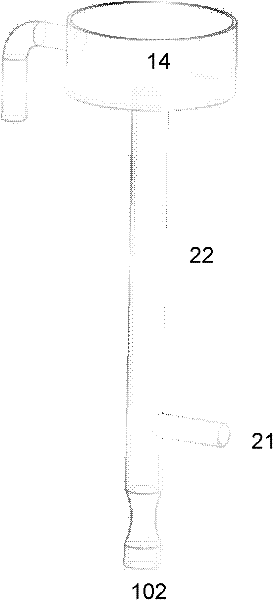

[0066] Embodiment 1, single-thin-layer tunnel-coupled photobioreactor

[0067] see Figure 6 , this model is the most intuitive form of expression of the present invention, and it comprises two interconnected thin-layer inclined tunnels 1 (high-position thin-layer tunnel and low-position thin-layer tunnel), a group of flat plate reactors 10, high-pressure blower 2, a high-level tank 14. Two sets of liquid flow distributors 11, one set of liquid level control system, one set of temperature control system, gas mixing system, expansion plate, etc. The angle between the thin-layer inclined corridor 1 and the horizontal plane is 1-3°, the length is 5-100m, and the width is 0.2-1.0m; the bottom of each thin-layer corridor 1 is equipped with an electric lifting device, which can be adjusted by controlling the lifting device. The angle between inclined corridor 1 and the horizontal plane. The model is relatively small in scale and can be used for basic research in laboratory applica...

Embodiment 2

[0068] Embodiment two, step-shaped coupled photobioreactor

[0069] see Figure 7 , the model is another intuitive form of expression of the present invention, and its open pool part is a ladder structure, which constitutes another form of thin-layer inclined corridor. The algae liquid slowly flows from the uppermost step to the bottom step, and the algal cells can receive sufficient light for growth during the flow. The number of steps can be set according to the scale of cultivation, and this model only needs a set of liquid flow distributors 11 to achieve uniform distribution of algae liquid. When the cultivation scale of the system is large, it may be considered to increase the aforementioned "liquid flow ascending system", thereby accelerating the circulation of the algae liquid.

Embodiment 3

[0070] Embodiment three, double-thin-layer tunnel coupled photobioreactor

[0071] see Figure 8 , the model is given by Figure 6 The "single-channel coupled photobioreactor" shown is improved, and the cultivation scale of the "single-thin-layer tunnel-coupled photobioreactor" is relatively small. When a high-level passage is added to it, the cultivation scale will be doubled. Figure 8 Among them, the double-thin-layer tunnel coupled photobioreactor has two high-level thin-layer tunnels, one low-level thin-layer tunnel, two high-level tanks, etc., which can realize the rapid circulation of algae liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com