A kind of porous inorganic film used as lithium ion battery separator and preparation method thereof

A lithium-ion battery, inorganic membrane technology, applied in battery pack parts, circuits, electrical components, etc., to achieve good high and low temperature performance, improve the applicable temperature, and shorten the cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.3g of nano-scale alumina, 0.3g of micron-scale alumina and 0.4g of ethylenediaminetetraacetic acid, mix and grind to obtain a mixture powder, weigh 0.25g of the above-mentioned mixture powder into a mold, and place it under a pressure of 16MPa After pressing into a diaphragm, the obtained diaphragm was sintered in a muffle furnace at 1000°C for 5 hours, cooled to room temperature naturally, and then sintered in a muffle furnace at 1600°C for 5 hours, cooled naturally to room temperature, and immersed in deionized water at 35kHz. Perform ultrasonic cleaning at 100 W for 3 minutes, take it out and then immerse in ethanol, perform ultrasonic cleaning for 3 minutes, and dry in a vacuum oven at 80° C. for 8 hours to obtain the porous inorganic membrane of the present invention.

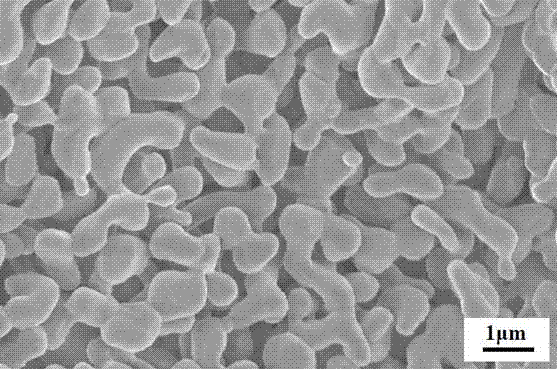

[0029] Such as figure 1 As shown, under the scanning electron microscope, the porosity of the porous inorganic film of the present invention is greater than 70%.

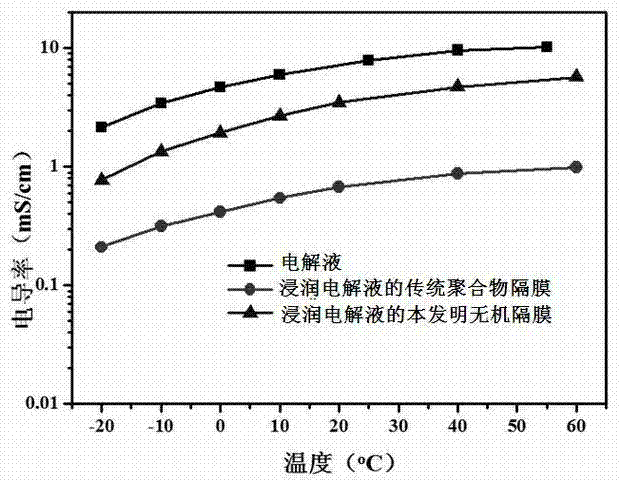

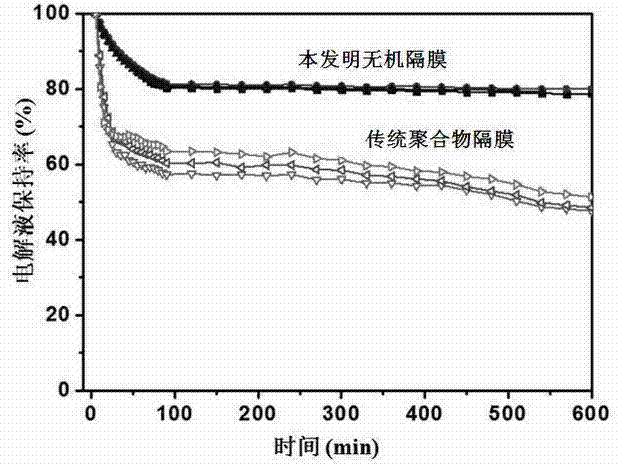

[0030] The porous inorganic mem...

Embodiment 2

[0035] Weigh 0.3g nanometer calcium oxide, 0.3g micrometer calcium oxide and 0.4g ammonium bicarbonate, mix and grind to obtain a mixture powder, weigh 0.25g of the above mixture powder into a mold, and press it under a pressure of 2MPa Diaphragm, the obtained diaphragm is sintered in a muffle furnace at 300°C for 10 hours, cooled to room temperature naturally, and then sintered in a muffle furnace at 300°C for 10 hours, naturally cooled to room temperature, and immersed in deionized water at 40kHz, 100W Carry out ultrasonic cleaning for 1 min, take it out and then immerse in ethanol, carry out ultrasonic cleaning for 1 min, and dry in a vacuum oven at 80° C. for 6 h to obtain the porous inorganic membrane of the present invention.

Embodiment 3

[0037] Weigh 0.5g of micron-grade alumina and 0.5g of ethylenediaminetetraacetic acid, mix and grind to obtain a mixture powder, weigh 0.25g of the above-mentioned mixture powder into a mold, and press it into a diaphragm under a pressure of 16MPa. The diaphragm was sintered in a muffle furnace at 1000°C for 5 hours, cooled to room temperature naturally, and then sintered in a muffle furnace at 1600°C for 5 hours, cooled to room temperature naturally, immersed in deionized water at 45kHz, 100W for ultrasonic cleaning for 3 minutes, After being taken out, it is immersed in ethanol, ultrasonic cleaning is performed for 3 minutes, and dried in a vacuum oven at 80° C. for 8 hours to obtain the porous inorganic membrane of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com