A temperature compensation method and device for an erbium-doped fiber superfluorescent light source pump laser

A temperature compensation device, a technology for pumping lasers, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of no exact compensation method, increase the complexity of the optical path, increase the power consumption of the light source, etc., to achieve power consumption Low, improved temperature stability, improved rotational sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

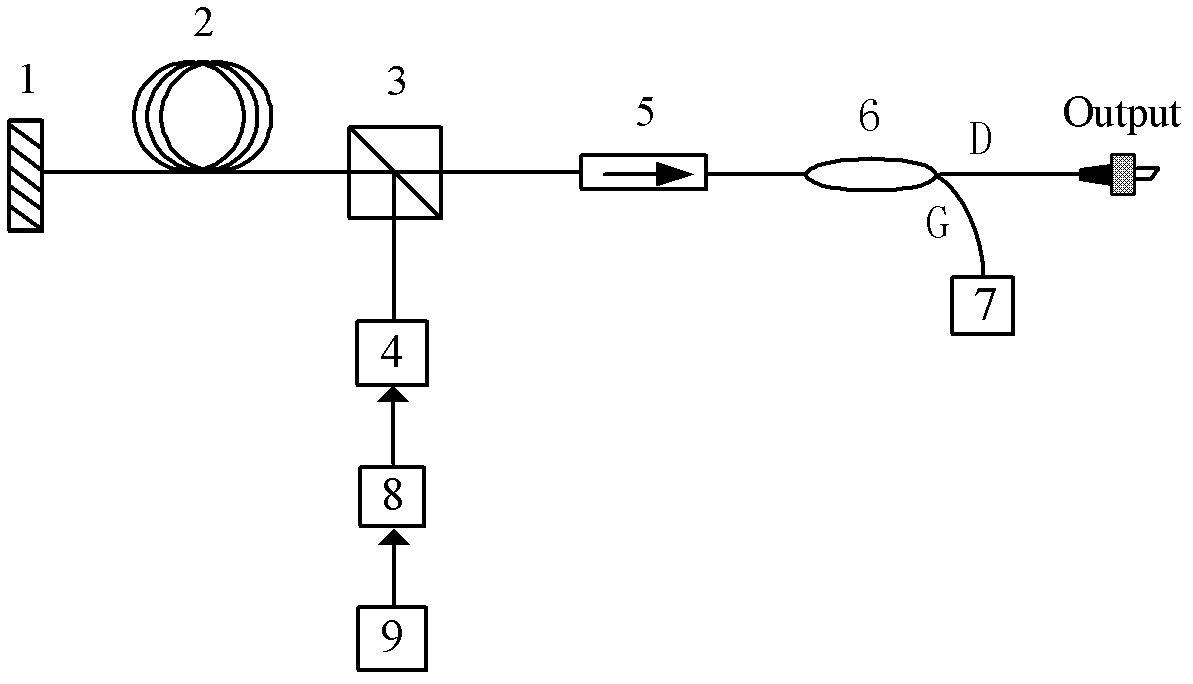

[0043] The temperature compensation method and device for the SFS light source pump laser of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

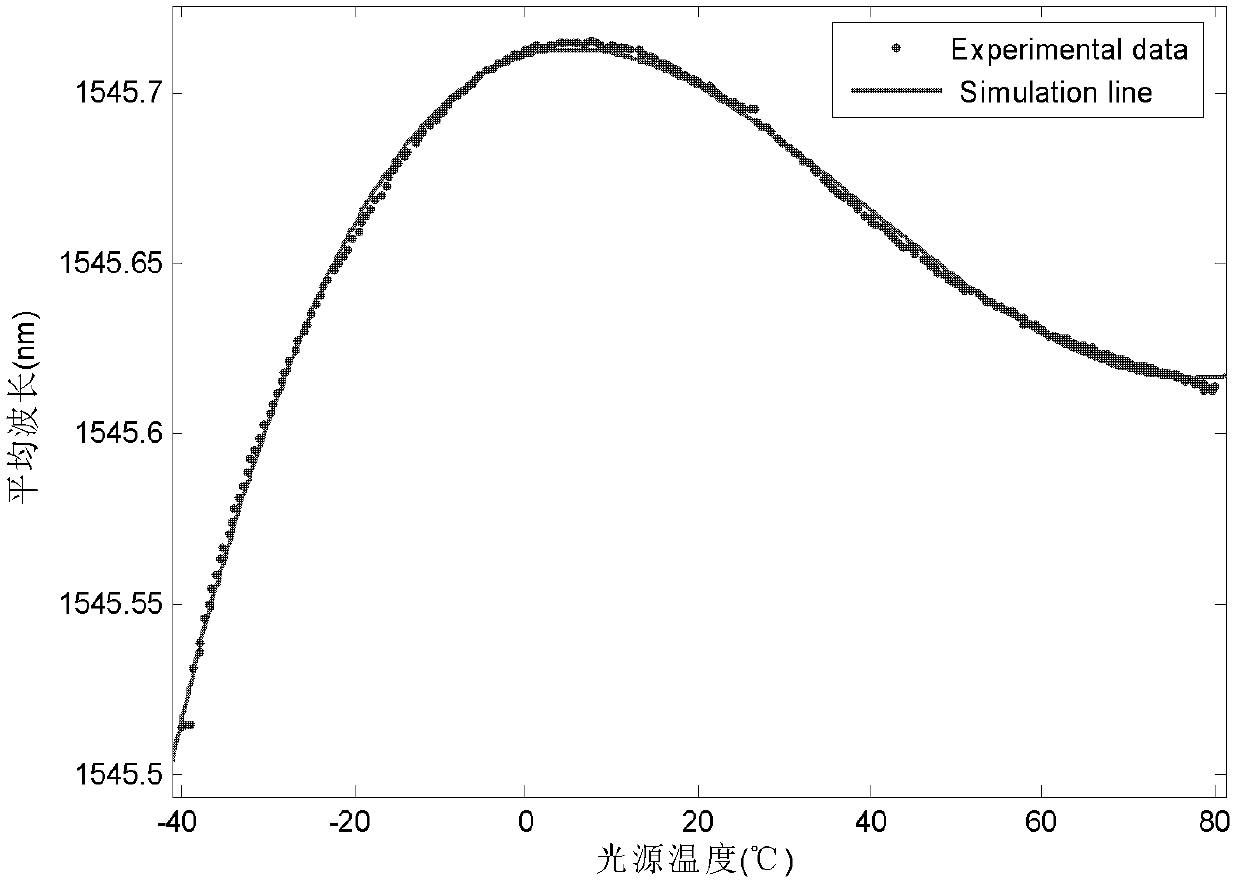

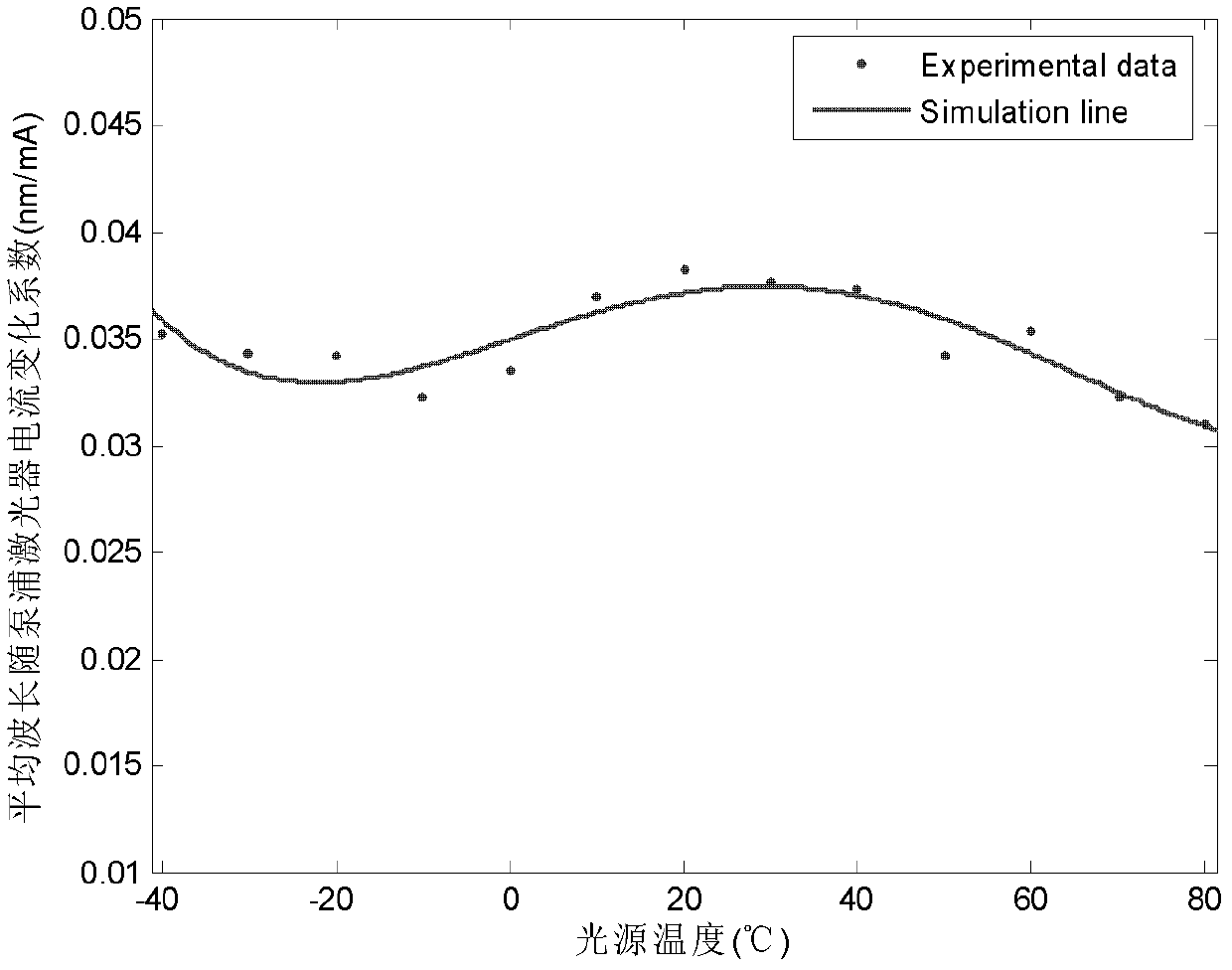

[0044]The working principle of the temperature compensation method of a SFS light source of the present invention is as follows: the operating wavelength, power, polarization state of the pump laser, the optical feedback at the output end of the light source and the temperature-related loss of the passive device will all change with the change of the temperature of the light source. Changes in the above factors will cause the average wavelength of the light source to change, and the biggest factor that causes the average wavelength of the light source to change is the gain coefficient and absorption coefficient of the erbium-doped fiber that changes with temperature. The change of the operating wavelength of the pump laser with temperature is determined by the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com