Renewable flue gas desulphurization process

A desulfurization process, a technology for regenerating flue gas, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of large loss of desulfurization solution, system blockage, and high suspended impurity content, reduce desorption energy consumption, prevent The effect of system blockage and improvement of desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

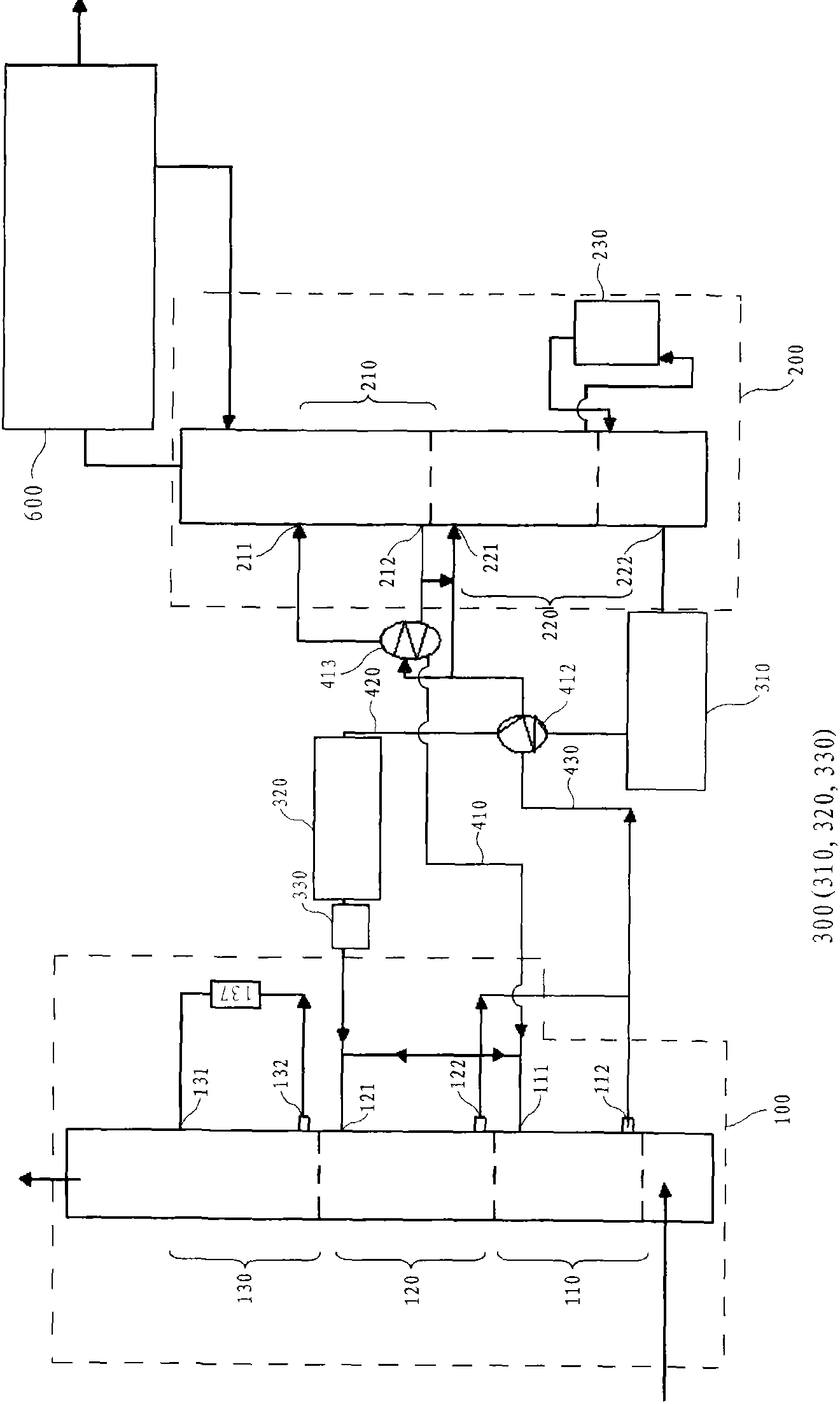

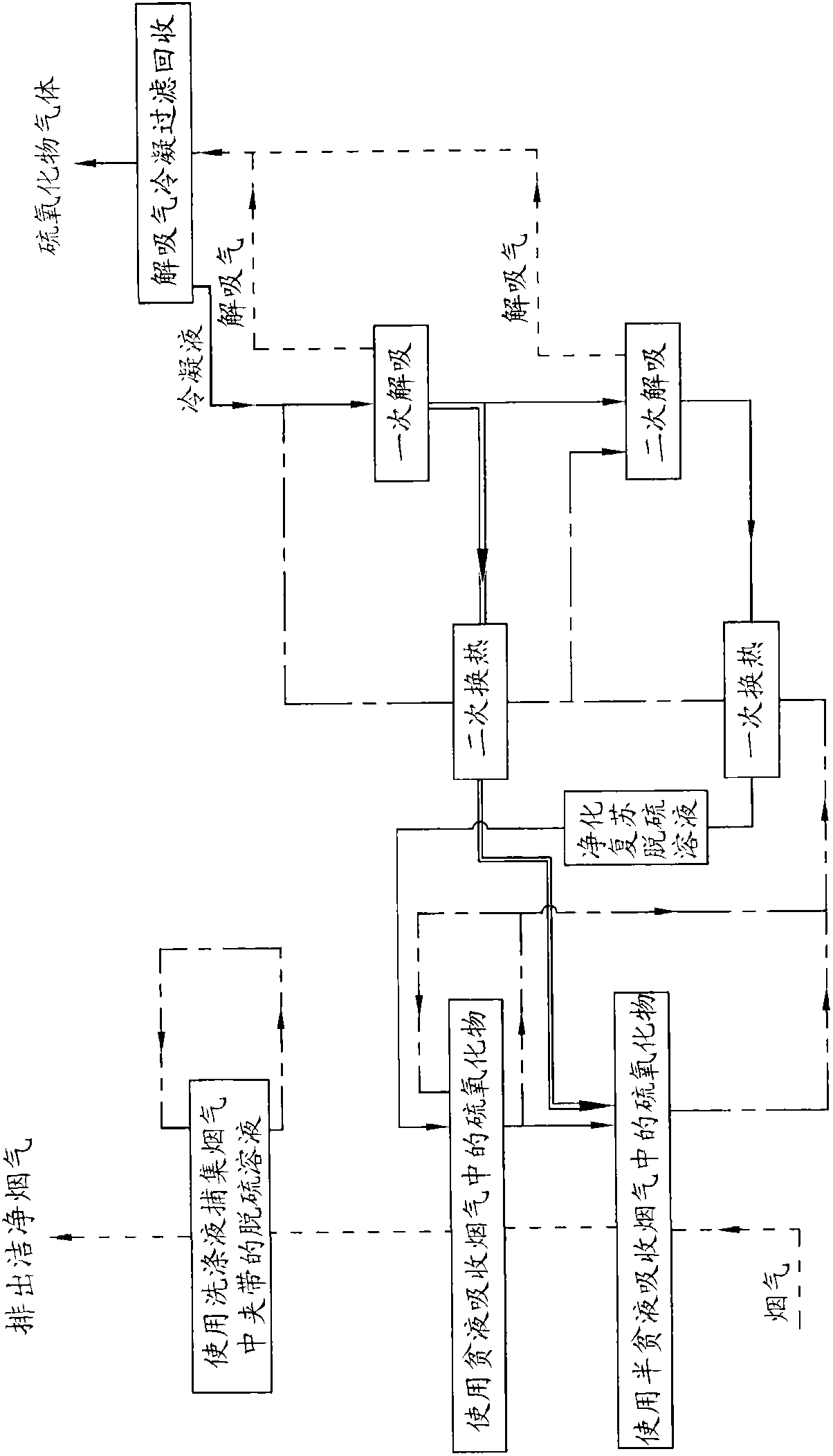

[0056] Figure 1A A schematic diagram of a device for implementing a regenerative flue gas desulfurization process according to a first exemplary embodiment of the present invention is shown, Figure 1B A schematic diagram of a regenerative flue gas desulfurization process according to a first exemplary embodiment of the present invention is shown.

[0057] Such as Figure 1A As shown, the device for implementing this exemplary embodiment may include: an absorption system 100, which absorbs sulfur dioxide in the flue gas by making the lean liquid countercurrently contact with the flue gas to be treated in the absorption tower, and forms rich liquid and purified gas; desorption System 200, desorbs rich liquid through desorption tower and reboiler to form new lean liquid and desorbed gas; desulfurization solution purification and recovery system 300, removes impurity ions in desorbed lean liquid through resin desalination; desorption gas treatment System 600, using a desorptio...

Embodiment 2

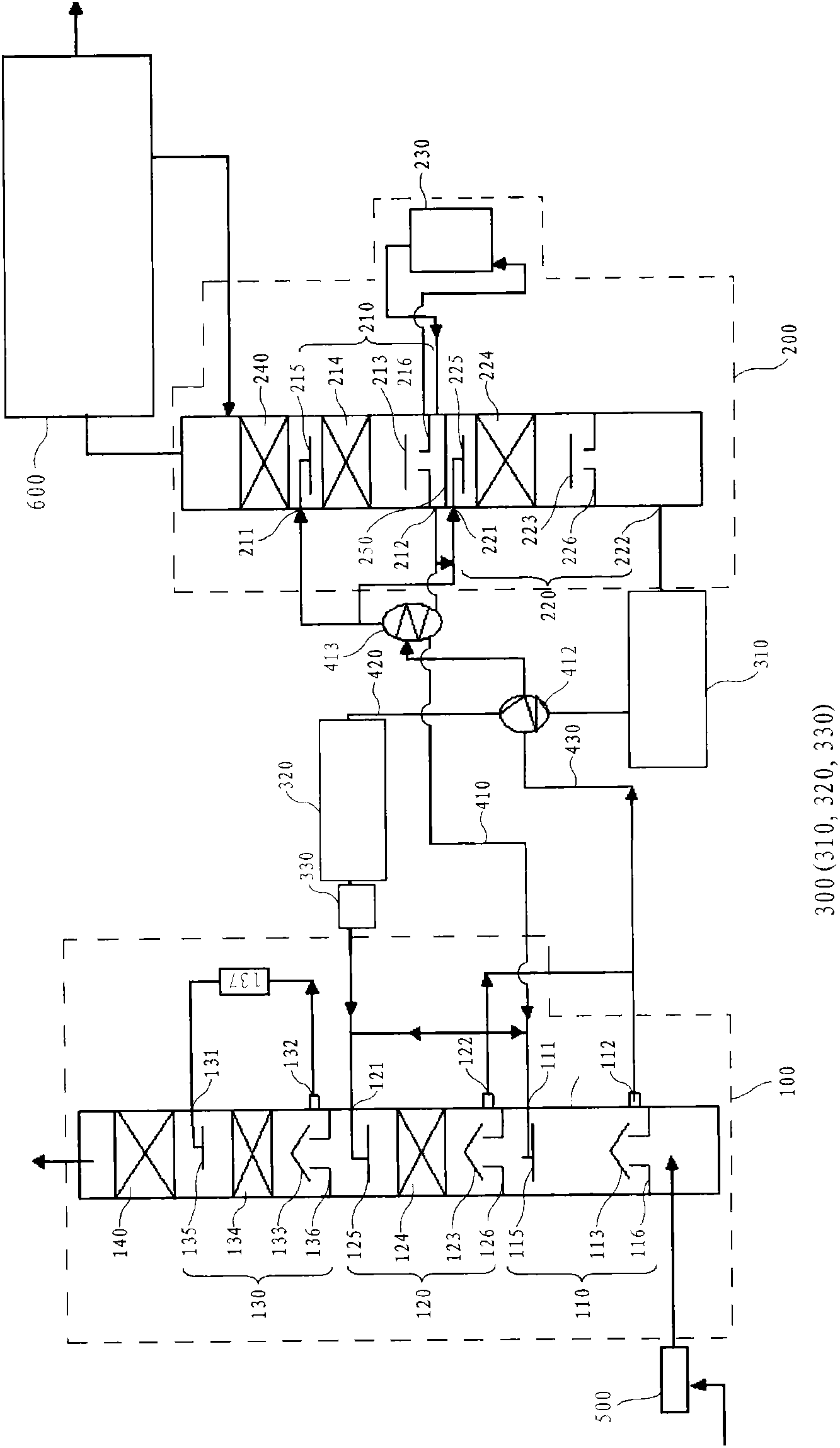

[0072] Figure 2A A schematic diagram of a device for implementing a regenerative flue gas desulfurization process according to a second exemplary embodiment of the present invention is shown, Figure 2B A schematic diagram of a regenerative flue gas desulfurization process according to a second exemplary embodiment of the present invention is shown.

[0073] Such as Figure 2A As shown, the difference between the device for realizing this exemplary embodiment and the device for realizing Embodiment 1 lies in the following:

[0074] (1) The apparatus for realizing the present exemplary embodiment includes the washing system 500 . The flue gas washing system 500 is arranged before the absorption system, and is used for washing the flue gas containing sulfur dioxide that is about to enter the absorption system 100, so as to remove impurities such as dust contained in the flue gas. In addition, for the case where the temperature of the flue gas to be treated is relatively high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com