Manufacturing method for mite-proof polyethylene light conveyer belt

A light-duty conveyor belt and manufacturing method technology, applied in the direction of belts, household appliances, other household appliances, etc., can solve the problems of easy production of mites, health hazards of tobacco products, light-duty conveyor belts contaminated with mites and reproduction, and achieve high chemical stability and Thermal stability, good compatibility, and the effect of inhibiting the regeneration of mites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

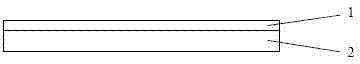

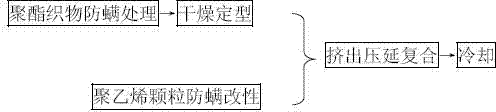

[0024] see figure 2 As shown in the process flow chart of the anti-mite PE light-duty conveyor belt of the present invention, a method for manufacturing an anti-mite polyethylene light-duty conveyor belt, wherein the light-duty conveyor belt is made of anti-mite treated polyester fabric and anti-mite modified It is made of composite polyethylene material, and the manufacturing method includes the following steps:

[0025] The first step: the anti-mite agent (the active ingredient is isothiazolinone compounds, that is, 5-chloro-2-methyl-4-isothiazolin-3-one / 2-methyl-4-isothiazoline- 3-ketone, RHZL-03 provided by Shanghai Runhe Nano Technology Co., Ltd.) Add water to make an anti-mite treatment solution with a concentration of 50-100g / L;

[0026] Step 2: Immerse the polyester fabric in the anti-mite treatment liquid in the first step, the impregnation amount is 150-200g / m 2 , drying and characterization by far-infrared heating, the drying temperature is 80-90 ° C, and the ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com