Preparation method of sulfur-doped TiO2 film for water purification system of construction site

A water purification system and construction site technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the difficulty of separating and reusing titanium dioxide particles and colloidal catalyst suspensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A sulfur-doped TiO for construction site water purification system 2 The preparation method of the film includes the following steps:

[0035] S1. Synthesis of sol: using a sol-gel process of self-assembly of non-sulfided hydrocarbon surfactants as a pore orienting agent, and using sulfuric acid as a precursor for sulfur and water production;

[0036] S2. Sulfur-doped TiO 2 Preparation of thin films: Preparation of sulfur-doped TiO using borosilicate glass as substrate 2 film;

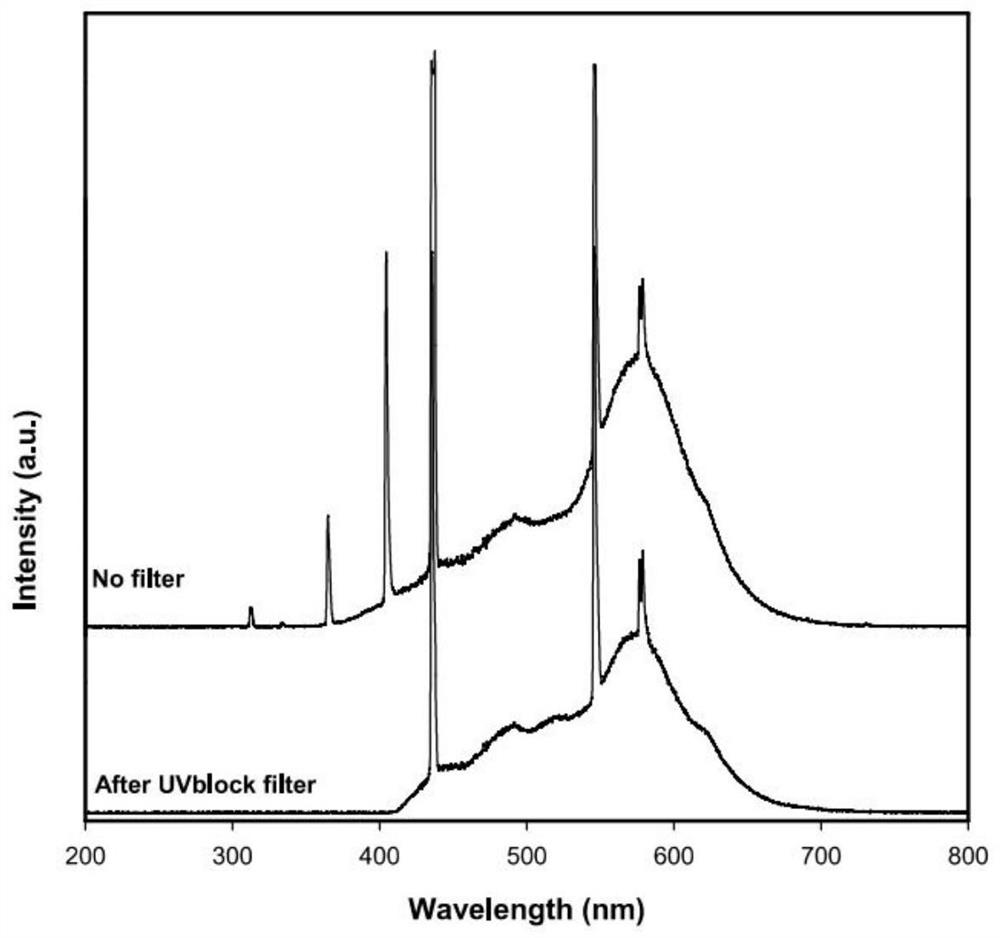

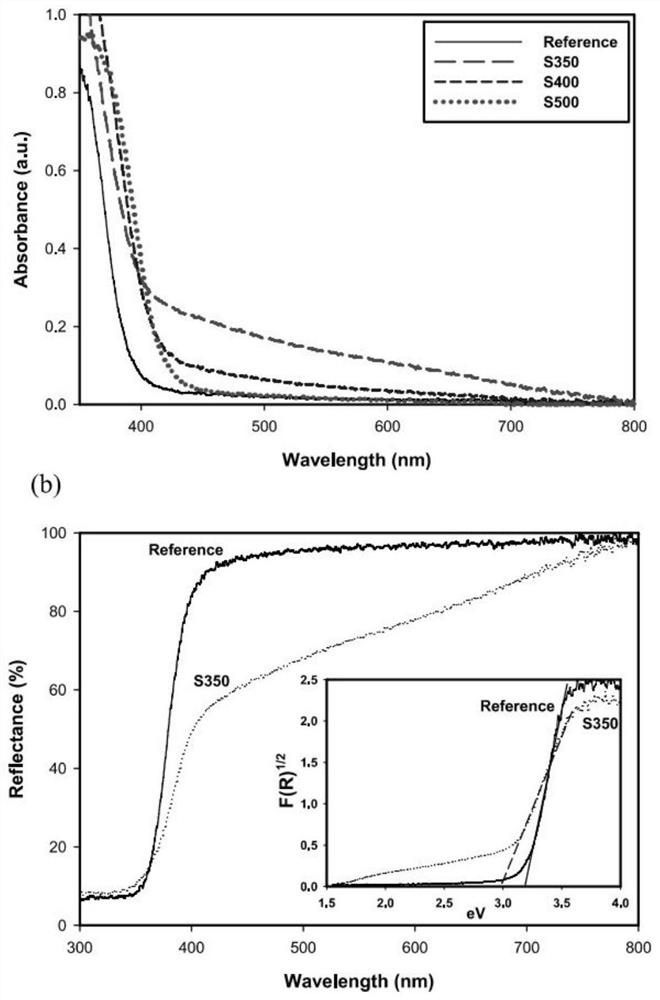

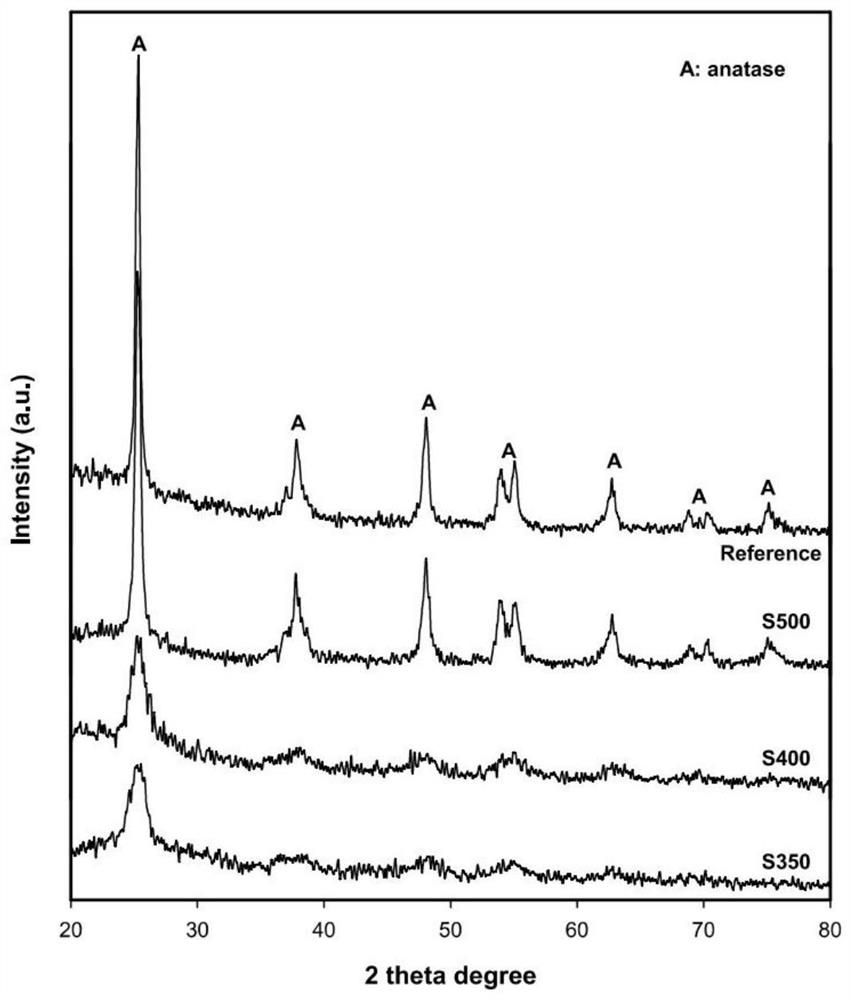

[0037] S3. Synthesized sulfur-doped TiO 2 Characterization of Thin Films: Measurements Using X-ray Diffractometer to Determine Synthetic Sulfur-Doped TiO 2 The crystal structure of the thin film;

[0038] Photocatalytic activity of S4.MC-LR under visible light irradiation: the solution was prepared in a reactor followed by addition of sulfur-doped TiO 2 film.

[0039] S1 includes the following steps:

[0040] S101. The nonionic surfactant polyoxyethylene (80) sorbitan monooleate (Tween 80)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com