Method for preparing stannous sulfamate solution and application thereof

A technology of stannous sulfamic acid and sulfamic acid, which is applied in the directions of sulfamic acid, nitrogen and non-metallic compounds, can solve the problems of difficult to handle barium sulfate by-products, difficult product quality requirements, difficult control of reaction end points, etc. The effect of less impurity ions, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

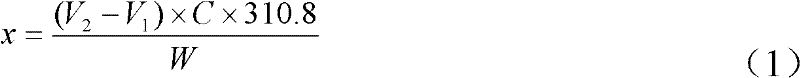

Method used

Image

Examples

Embodiment 1

[0033] Weigh 134 grams of stannous oxide in a 2000 mL beaker, add 500 mL of pure water and stir to wash off the surface impurities, pour off the upper layer after sinking for a while, add 204 grams of sulfamic acid, 500 grams of pure water, Diphenol, 0.2 g of tartaric acid, heated to 60° C. and stirred (125 r / min) for 3 hours to dissolve completely, then added 1 g of activated carbon, filtered after 30 minutes of adsorption, and obtained the filtrate. After measuring the content 417g / L of stannous sulfamate in the filtrate, add the stannous sulfamate solution of pure water preparation 300g / L (in terms of stannous sulfamate). The solution after the deployment is tested again, and the concentration of this stannous sulfamate solution is 301.2g / L (in terms of stannous sulfamate), and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is even <10ppm.

Embodiment 2

[0035] Weigh 134 grams of stannous oxide in a 2000 mL beaker, add 500 mL of pure water to stir and wash off the surface impurities, pour off the upper layer after sinking for a period of time, add 214 grams of sulfamic acid, 500 grams of pure water, and 0.5 grams of hydroxylamine hydrochloride , 0.2 grams of tartaric acid, heated to 70 ° C and stirred (150r / min) for 4 hours to make it completely dissolved, added 1.5 grams of activated carbon, filtered after 30 minutes of adsorption, and the filtrate was taken. After measuring the content 422g / L of stannous sulfamate in the filtrate, add the stannous sulfamate solution of pure water preparation 300g / L (in terms of stannous sulfamate). The solution after the deployment is tested again, and the concentration of this stannous sulfamate solution is 300.8g / L (in terms of stannous sulfamate), and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is even. <10ppm.

Embodiment 3

[0037] Weigh 134 grams of stannous oxide in a 2000 mL beaker, add 500 mL of pure water and stir to wash off the surface impurities, pour off the upper layer after sinking for a period of time, add 213 grams of sulfamic acid, 500 grams of pure water, 0.5 grams of m-benzene Diphenol, 0.2 gram of tartaric acid, heated to 90 DEG C and stirred (100r / min) to react for 2 hours to make it completely dissolved, add 1 gram of activated carbon, filter after 30 minutes of adsorption, take the filtrate, and measure the content of stannous sulfamate in the filtrate 407g / L, add pure water to prepare 300g / L (calculated as stannous sulfamate) stannous sulfamate solution. The solution after the deployment is tested again, and the concentration of this stannous sulfamate solution is 300.5g / L (in terms of stannous sulfamate), and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is even. <10ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com