Combined process for building partial nitrosation-anaerobic ammonium oxidation garbage percolate

A landfill leachate and anaerobic ammonium oxidation technology, applied in the field of environmental protection, can solve the problems of unsatisfactory treatment effects, achieve the effects of reducing treatment costs, being environmentally friendly, reducing chemical input and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

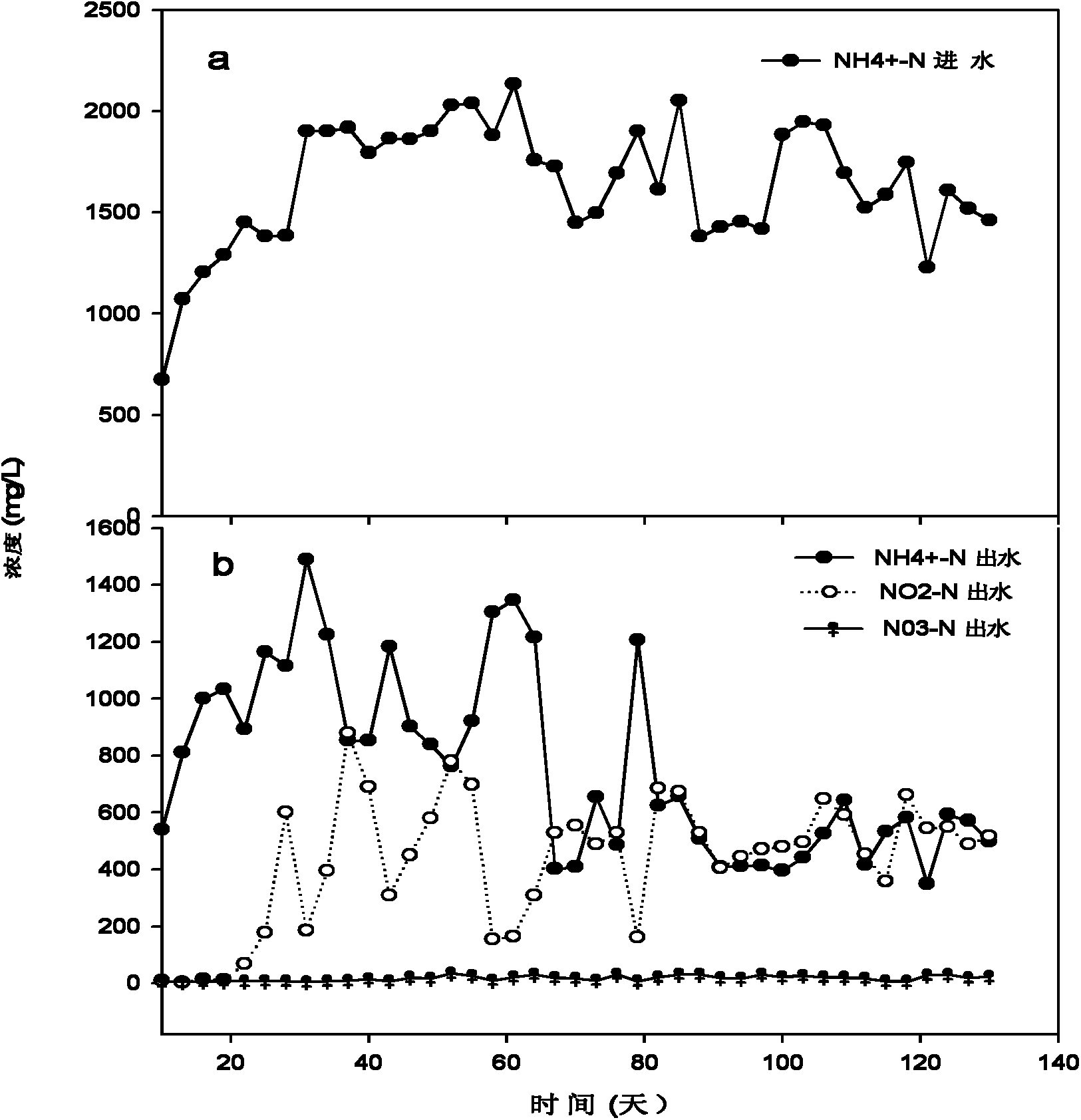

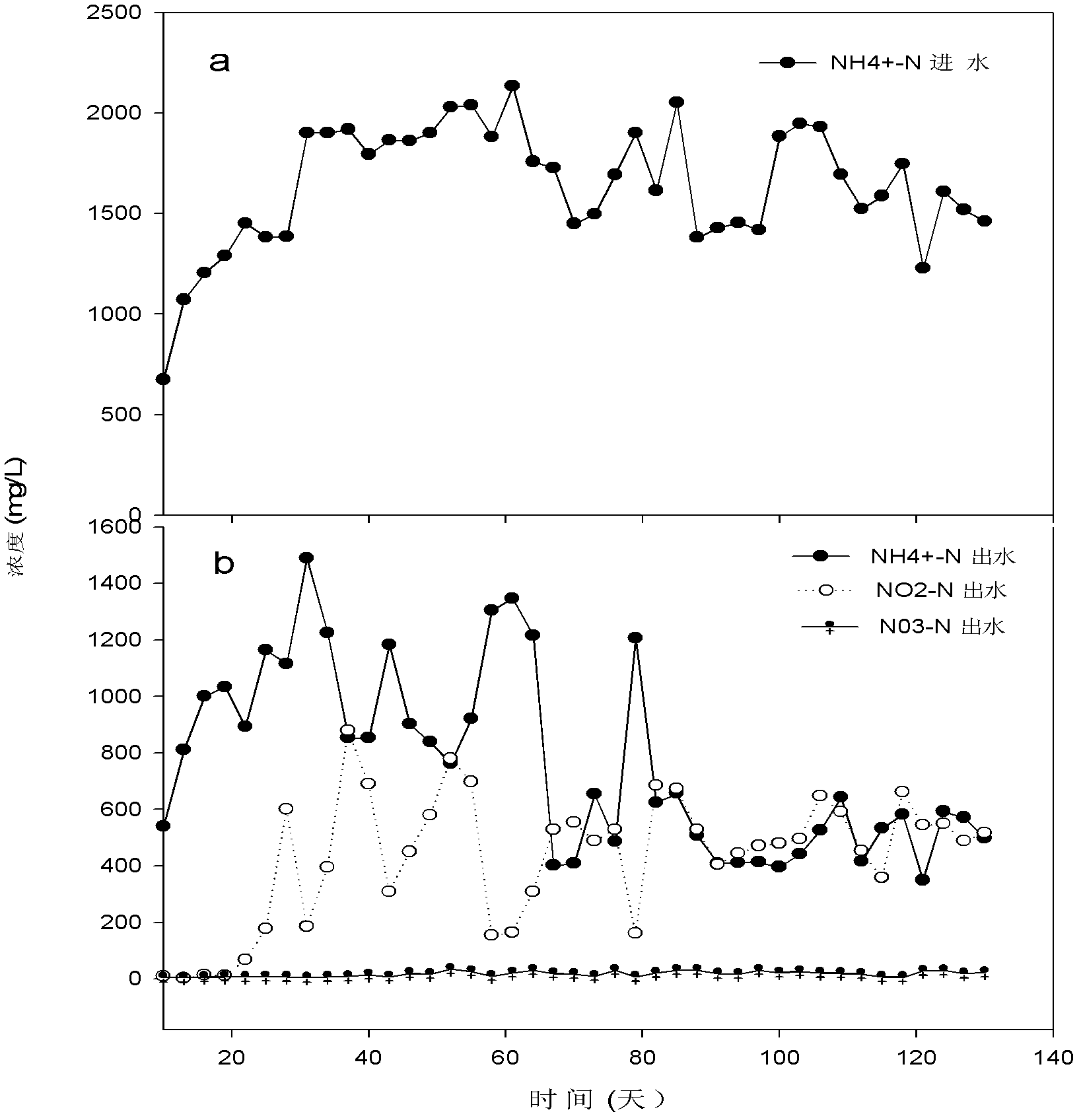

[0019] Inoculate the mixed sludge in the SBR reactor (the sludge of the secondary sedimentation tank of the domestic sewage treatment plant and the sludge of the biochemical tank of the landfill leachate treatment plant are mixed in a mass ratio of 1:1).

[0020] Inoculate the mixed sludge in the ABR reactor (the sludge of the secondary sedimentation tank of the domestic sewage treatment plant and the sludge of the biochemical tank of the landfill leachate treatment plant are mixed at a mass ratio of 1:1), and use artificial water distribution to domesticate and enrich anammox bacteria , so that the ABR reactor starts and reaches stability. Artificial water distribution is to add ammonia nitrogen and nitrite to the basic inorganic salt medium, the concentration of ammonia nitrogen is 260mg / L, the concentration of nitrite nitrogen is 320mg / L, and the pH value is controlled at about 8.0.

[0021] Contains NaHCO per liter of Minimal Mineral Salt Medium 3 1.25g, KH 2 PO 4 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com