Polyazomethine hole transport material and preparation method thereof

A technology of hole transport material and polymethylimide, which is applied in the directions of luminescent materials, chemical instruments and methods, can solve problems such as affecting device performance, and achieve the effect of good solubility and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

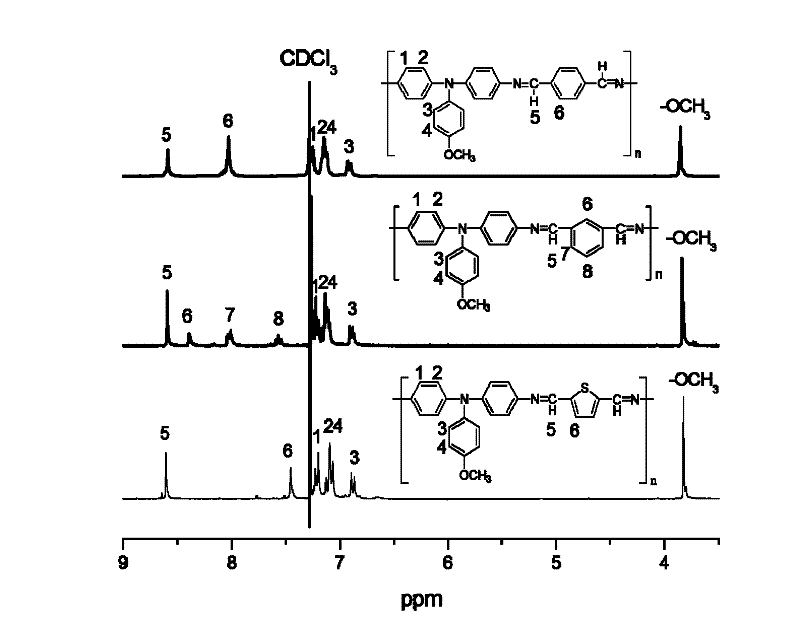

[0028] In a 30ml three-necked flask equipped with a stirrer, nitrogen protection, and 20°C oil bath, add N,N-bis(4-aminophenyl)-4methoxyaniline (3.1g, 0.010mol), terephthalate Formaldehyde (1.3g, 0.010mol), 0.1g of anhydrous calcium chloride, anhydrous NMP solvent (39.6ml), reacted for 24 hours; then discharged and in absolute ethanol, the obtained solid was extracted with ethanol for 12 hours, vacuum Dry at 50°C for 7 hours to obtain polymer P1. Its Tg is 240°C, the 5% thermal decomposition temperature under nitrogen is 511°C, and the hole mobility is 1.84×10 -4 cm 2 V -1 the s -1 .

Embodiment 2

[0030] In a 30ml three-neck flask equipped with a stirrer, nitrogen protection, and 25°C oil bath, add N,N-bis(4-aminophenyl)-4methoxyaniline (3.1g, 0.010mol), m-phenylene Formaldehyde (1.3g, 0.010mol), 0.1g of anhydrous lithium chloride, anhydrous DMF solvent (39.6ml), reacted for 36 hours; then discharged and in absolute ethanol, the obtained solid was extracted with ethanol for 12 hours, vacuum Dry at 55°C for 8 hours to obtain polymer P2. Its Tg is 200°C, the 5% thermal decomposition temperature under nitrogen is 525°C, and the hole mobility is 1.09×10 -4 cm 2 V -1 the s -1 .

Embodiment 3

[0032] In a 30ml three-neck flask equipped with a stirrer, nitrogen protection, and 30°C oil bath, add N,N-bis(4-aminophenyl)-4methoxyaniline (3.1g, 0.010mol), 2,5 - Thiophenedicarbaldehyde (1.4g, 0.010mol), 0.1g of anhydrous calcium chloride, anhydrous DMAc solvent (39.6ml), reacted for 48 hours; then discharging and dehydrated ethanol, the solid obtained, ethanol extraction 24 Hours, vacuum drying at 60°C for 9 hours to obtain polymer P3. Its Tg is 215°C, and its 5% thermal decomposition temperature under nitrogen is 476°C. The hole mobility was not tested for solubility reasons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com