Gasoline engine cylinder head assembly and gasoline engine

A gasoline engine and cylinder head technology, which is applied to power machine components and its application fields, can solve problems such as increasing the valve arrangement range, affecting the arrangement of pushrods and camshafts, and affecting the arrangement of other components, so as to avoid mutual staggering, improve performance, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

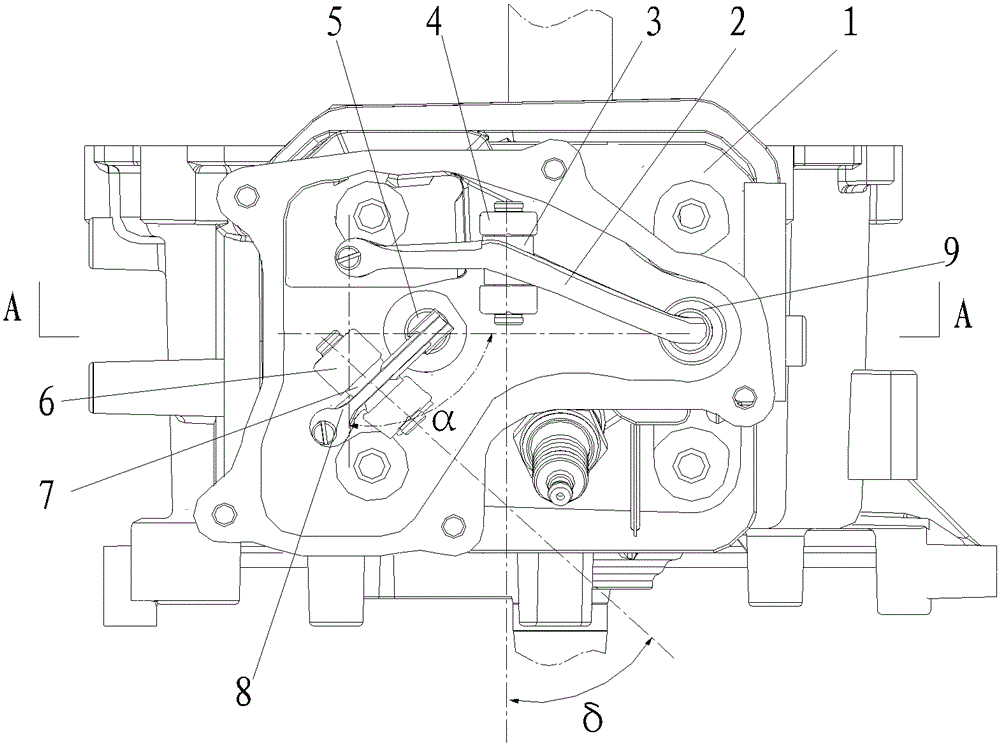

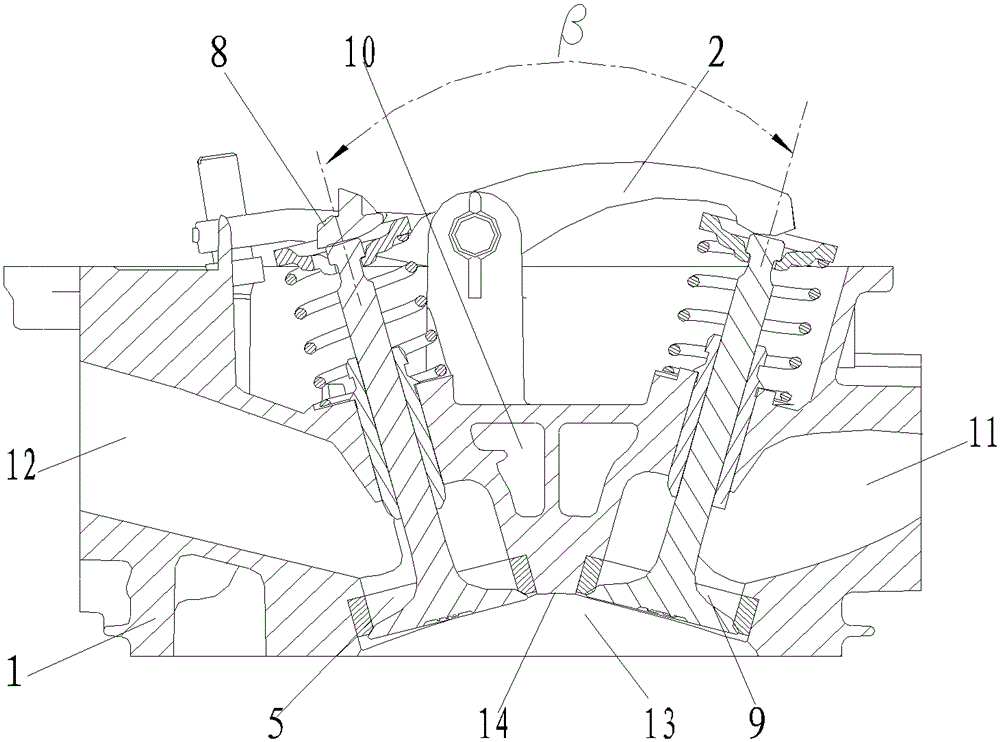

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A sectional view along the direction of A-A, as shown in the figure: the gasoline engine cylinder head assembly of this embodiment includes a cylinder head body 1, an intake passage 12 and an exhaust passage 11 arranged on the cylinder head body 1, and the inside of the cylinder head body 1 forms a combustion chamber. On the chamber surface 13, the cylinder head body 1 is provided with an intake valve 5 corresponding to the intake passage 12, an exhaust valve 9 is provided corresponding to the exhaust passage 11, and an intake rocker arm 8 and an intake valve 5 are correspondingly provided. The air push rod (not marked in the figure), the exhaust valve 9 is correspondingly provided with an exhaust rocker arm 2 and an exhaust push rod (not marked in the figure), the top of the intake valve 5 is inclined to the side of the intake passage 12, and the exhaust The top of the door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com