Rotary separating type intelligent radiation sensor

A radiation sensor, a separate technology, applied in the field of radiation sensors, can solve the problems of abnormal stop of motor system action, no level bubble indication, vibration, etc., to avoid measurement errors, prolong service life, and facilitate installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

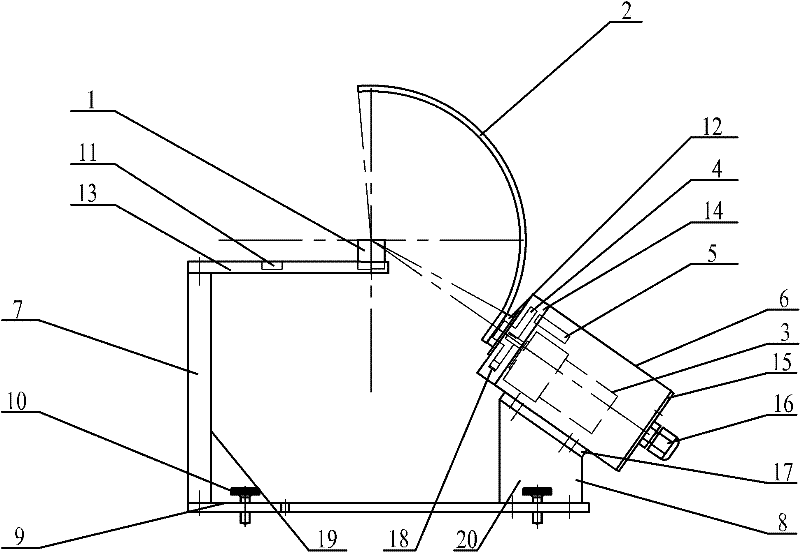

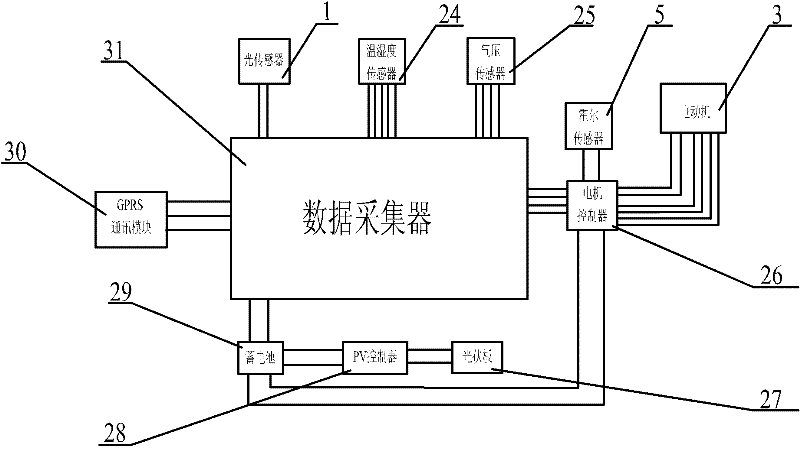

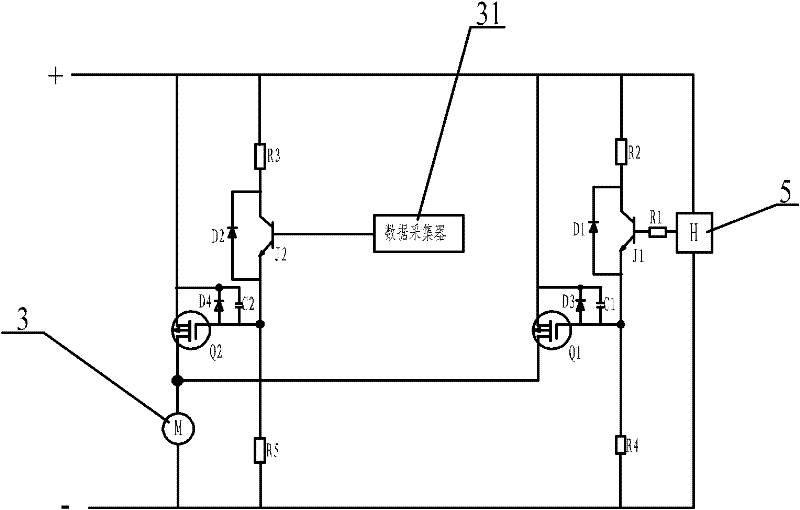

[0039] Such as Figure 1 to Figure 6 and Figure 9 ~ Figure 12 As shown: the present invention includes a light sensor 1, a shading ring 2, a motor 3, a rotating disk 4, a first Hall sensor 5, a motor cover 6, a sensor support plate 7, a motor support plate 8, a bottom plate 9, an adjustment screw 10, Level bubble 11, waterproof cover 12, sensor mounting plate 13, front cover 14, rear cover 15, aviation plug 16, motor mounting plate 17, first magnet 18, light sensor mounting bracket 19, motor mounting bracket 20, threading hole 21, Optical sensor installation hole 22, optical sensor installation positioning plate 23, temperature and humidity sensor 24, air pressure sensor 25, motor controller 26, photovoltaic panel 27, PV controller 28, battery 29, GPRS communication module 30, data collector 31, sensor Mounting plate mounting hole 32, level bubble mounting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com