Compound modified polyolefin lithium ion battery separator and manufacturing method thereof

A technology of ion battery and compound modification, which is applied in battery components, chemical instruments and methods, circuits, etc., can solve the problems of reduced overall battery performance and safety, limited temperature resistance, poor electrolyte affinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

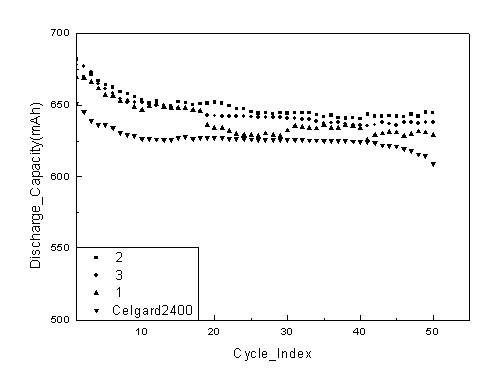

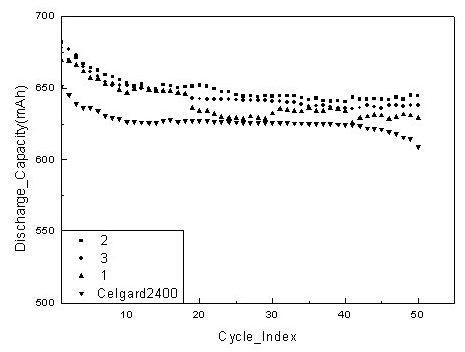

Image

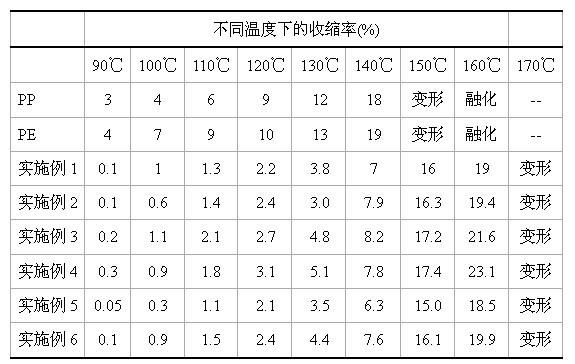

Examples

Embodiment 1

[0022] a. Preparation of sol-like polymer: 1g PVDF-HFP (molecular weight 900,000) and 0.2g diameter <50nm, the modified nano-silica with vinyl surface group is dissolved in 45ml of dimethylformamide (DMF) under the protection of N2, the temperature is controlled at 70℃, fully stirred until completely dissolved to form a sol-like polymer ,spare;

[0023] b. Surface pretreatment of polyolefin microporous membrane: corona pretreatment of polypropylene microporous membrane with a thickness of 20μm, machine speed 20m / min, corona power 500W, corona voltage 2-10kV, standby;

[0024] c. Coating film: The sol-like polymer obtained in step a is coated on one side of the polypropylene microporous film after the surface treatment in step b by a coating machine, and the thickness of the single-sided wet coating is controlled to be less than 5 μm, and the coating is wet Thin film battery separator, spare;

[0025] d. Drying to obtain a finished product: Transfer the wet film-coated battery diaphr...

Embodiment 2

[0027] a. Preparation of sol polymer: 1g PVDF-HFP (molecular weight 900,000) and 0.1g diameter <50nm, the modified nano-silica with vinyl surface group is dissolved in 40ml dimethylformamide (DMF) under the protection of N2, the temperature is controlled at 100℃, fully stirred until completely dissolved, forming a sol-like polymer ,spare;

[0028] b. Surface pretreatment of polyolefin microporous membrane: corona pretreatment of polyethylene microporous membrane with a thickness of 20μm, machine speed 20m / min, corona power 500W, corona voltage 2-10kV, standby;

[0029] c. Film coating: the sol-like polymer obtained in step a is coated on one side of the polyethylene microporous film after surface treatment in step b by a coating machine, and the thickness of the single-sided wet coating is controlled to be less than 5μm, and the coating is wet Thin film battery separator, spare;

[0030] d. Dry the finished product: Transfer the wet film-coated battery diaphragm obtained in step c ...

Embodiment 3

[0032] a. Preparation of sol-like polymer: 1g PVDF-HFP (molecular weight 900,000) and) 0.05g diameter <50nm, the modified nano-silica with vinyl surface group is dissolved in 40ml dimethylformamide (DMF) under the protection of N2, the temperature is controlled at 60℃, fully stirred until completely dissolved, forming a sol-like polymer ,spare;

[0033] b. Surface pretreatment of polyolefin microporous film: a three-layer composite film of polypropylene microporous film / polyethylene microporous film / polypropylene microporous film with a thickness of 40μm is subjected to corona pretreatment at a speed of 20m / min, Corona power 500W, corona voltage 2~10kV, spare;

[0034] c. Coated film: Coat the sol-like polymer obtained in step a on one side of the three-layer composite film after surface treatment in step b by a coating machine, and control the thickness of the single-sided wet coating to be less than 5μm, so that the wet film is coated Battery separator, spare;

[0035] d. Drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com