Capacitor-battery bipolar inline combined nickel-hydrogen power capacitor battery

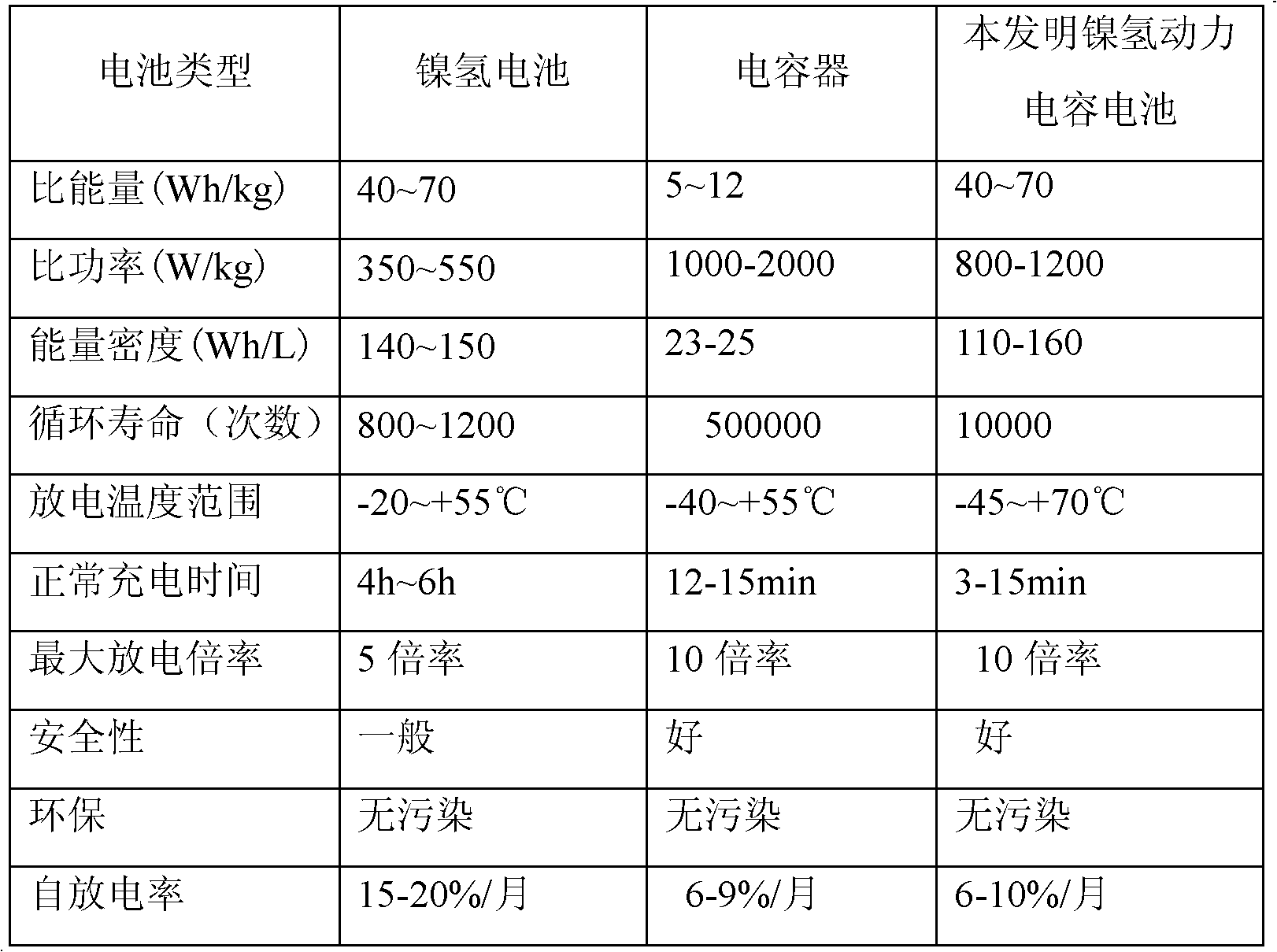

A capacitor cell and battery technology, applied in the direction of alkaline storage battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of lead pollution, low power density, poor low temperature performance, low capacity density, etc., to ensure high and low temperature work. Effectiveness of range and safety of use, long cycle life, rapid charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The negative electrode plate is made by coating the negative electrode mixed slurry on the nickel foam skeleton, and then dried, rolled, and cut into pieces. The positive plate is made by coating the positive electrode mixed slurry on the foamed nickel substrate, and dried, rolled, and cut. sheet made;

[0020] Wherein the mass percentage composition of each component of the negative electrode mixed slurry is as follows: 90% of rare earth alloy powder, 6% of carbonaceous material, 0.2% of binder, 3.4% of conductive agent, 0.3% of hydrophobic agent and 0.1% of modification liquid;

[0021] The mass percent composition of each component of the positive electrode mixed slurry is as follows: 90% nickel hydroxide, 5% carbonaceous material, 3.0% conductive agent, 0.5% binder and 1.5% hydrophobic agent.

[0022] Among them, the chemical composition of the rare earth alloy powder is composed of 54% nickel, 33% lanthanum, 6% cobalt, 2.1% aluminum, and 4.9% manganese; the carbona...

Embodiment 2

[0025] The negative electrode plate is made by coating the negative electrode mixed slurry on the nickel foam skeleton, and then dried, rolled, and cut into pieces. The positive plate is made by coating the positive electrode mixed slurry on the foamed nickel substrate, and dried, rolled, and cut. sheet made;

[0026] Wherein the mass percentage composition of each component of the negative electrode mixed slurry is as follows: 91% of rare earth alloy powder, 5% of carbonaceous material, 0.1% of binder, 3.5% of conductive agent, 0.2% of hydrophobic agent and 0.2% of modification liquid;

[0027] The mass percentage composition of each component of the positive electrode mixed slurry is as follows: 91% nickel hydroxide, 3% carbonaceous material, 3.5% conductive agent, 0.6% binder and 1.9% hydrophobic agent.

[0028] Among them, the chemical composition of rare earth alloy powder is composed of 57% nickel, 30% lanthanum, 6.9% cobalt, 1.5% aluminum, and 4.6% manganese; Cobalt po...

Embodiment 3

[0031] The negative electrode plate is made by coating the negative electrode mixed slurry on the nickel foam skeleton, and then dried, rolled, and cut into pieces. The positive plate is made by coating the positive electrode mixed slurry on the foamed nickel substrate, and dried, rolled, and cut. sheet made;

[0032] Wherein the mass percentage composition of each component of the negative electrode mixed slurry is as follows: 93% of rare earth alloy powder, 3% of carbonaceous material, 0.1% of binder, 3.7% of conductive agent, 0.1% of hydrophobic agent and 0.1% of modification liquid;

[0033] The mass percent composition of each component of the positive electrode mixed slurry is as follows: 92% nickel hydroxide, 2% carbonaceous material, 3.8% conductive agent, 0.7% binder and 1.5% hydrophobic agent.

[0034] Among them, the chemical composition of the rare earth alloy powder is composed of 56% nickel, 32% lanthanum, 5.5% cobalt, 1.8% aluminum, and 4.7% manganese; the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific energy | aaaaa | aaaaa |

| Specific power | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com