Electrochemical cell, portable electronic device and method for manufacturing electrochemical cell

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as the inability to curl the shell and seal, and achieve the effects of shortening welding time, improving reliability, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

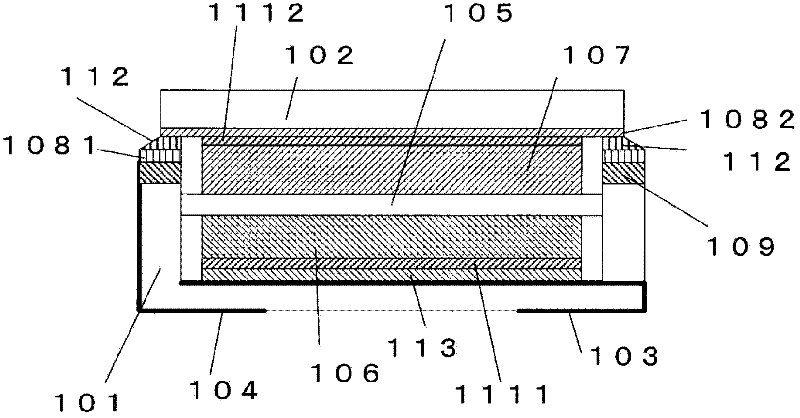

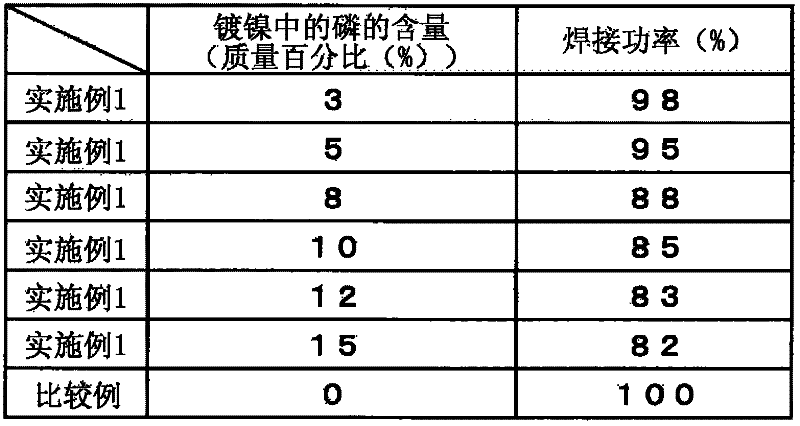

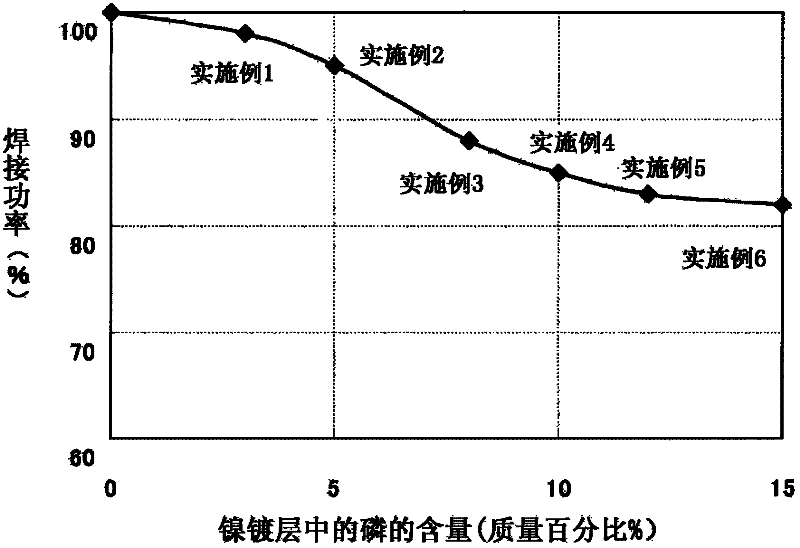

[0063] use figure 1 Example 1 was produced for the storage container shown. The concave container 101 is made of alumina and has a size of 3.2×2.5×0.9 mm. The depression depth of the concave portion was 0.4 mm, and the size thereof was 2.4×1.7 mm. The surface of the tungsten layer was plated with gold to form connection terminal A, connection terminal B, and a current collector. As the sealing plate 102, a nickel plating layer containing 3% by mass of phosphorus was formed on a Kovar plate with a thickness of 0.1 mm to a thickness of approximately 5 μm. As the metal ring 109 of the concave container 101, a ring obtained by forming a nickel plating layer containing 3% by mass of phosphorus to a thickness of about 5 μm was used.

[0064] The active material is used in activated carbon (the specific surface area is 2260m 2 / g) is a sheet obtained by adding carbon black as a conductive agent and using a Teflon (registered trademark) adhesive as an adhesive. This sheet is cut ...

Embodiment 2

[0067]Example 2 was prepared by setting the phosphorus content of the nickel plating layer disposed on both the metal ring 109 and the sealing plate 102 to 5% by mass. Other manufacturing conditions are the same as in Example 1.

Embodiment 3

[0069] Example 3 was prepared by setting the phosphorus content of the nickel plating layer disposed on both the metal ring 109 and the sealing plate 102 to 8% by mass. Other manufacturing conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap