Refined triphenyl fraction catalyst and preparation method and application thereof

A technology for triphenyl fraction and catalyst, which is applied in the field of refining triphenyl fraction catalyst and its preparation and application, can solve the problems of low catalyst activity and high bromine index of products, and achieve the effects of good stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation process of catalyst E-1 of the present invention is as follows:

[0029] (1) 1000 grams of mass concentration are lanthanum nitrate solution of 20% (calculated as lanthanum oxide) and 800 grams of hydrogen type Y molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 8.7, and the specific surface area is 726m 2 / g) were thoroughly mixed, then dried at 130° C. for 24 hours, and calcined at 750° C. for 3 hours to obtain a modified Y-type molecular sieve with a mass content of lanthanum oxide of 20%.

[0030] (2) 500 grams of ammonium chloride solution with a mass concentration of 10% (in terms of halogen) and 450 grams (in terms of aluminum oxide) of aluminum hydroxide (SB produced by German Condean Company) are fully mixed, and then heated at 50 ° C. Drying at low temperature for 48 hours, and calcining at 400°C for 8 hours to obtain modified alumina with a chlorine content of 6.8m%.

[0031] (3) the modified Y-type molecular sieve that 200 grams of steps...

Embodiment 2

[0033] The preparation of catalyst E-2 of the present invention

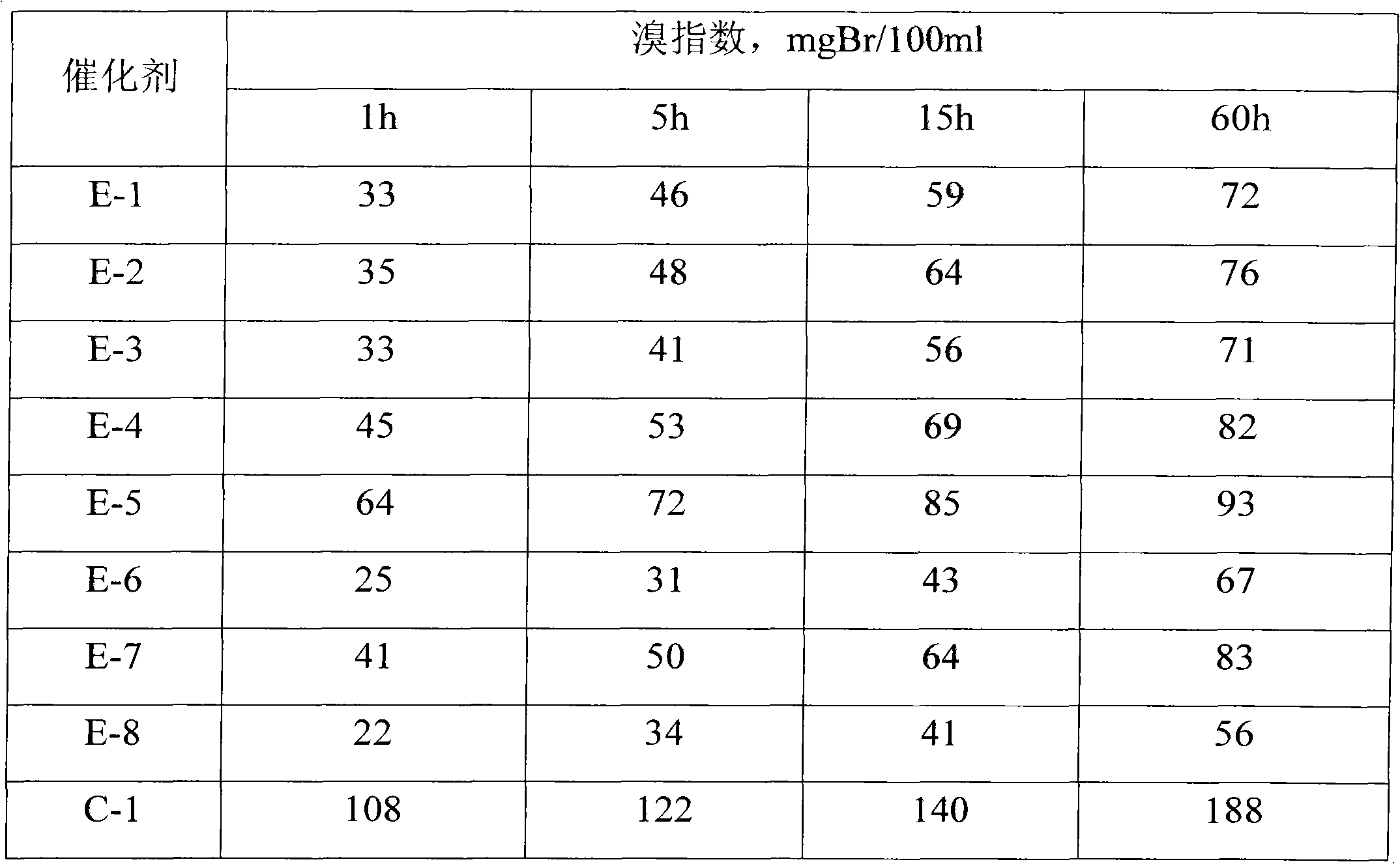

[0034] The preparation process of catalyst E-2 of the present invention is the same as that of Example 1, except that cerium nitrate is used to replace lanthanum nitrate. The prepared catalyst E-2 of the present invention has the composition shown in Table 1, and the product bromine index results are shown in Table 2 and Table 3. .

Embodiment 3

[0036] The preparation of catalyst E-3 of the present invention

[0037] The preparation process of catalyst E-3 of the present invention is the same as embodiment 1, and the difference is that hydrogen type β molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 26, and the specific surface area is 547m 2 / g) instead of hydrogen-type Y molecular sieve, the composition of the prepared catalyst E-3 of the present invention is shown in Table 1, and the bromine index results of the product are shown in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com