Urban life sludge locally self-circulation comprehensive utilization device and method

A technology for municipal domestic sludge and sludge, which is applied in combustion methods, dehydration/drying/thickened sludge treatment, lighting and heating equipment, etc., can solve secondary pollution and other problems, achieve cost saving, avoid pollution along the way, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

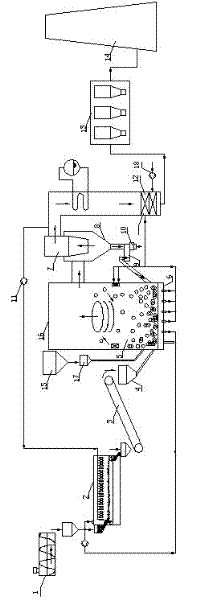

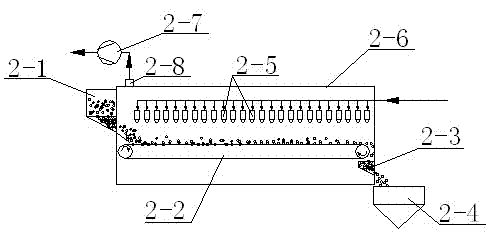

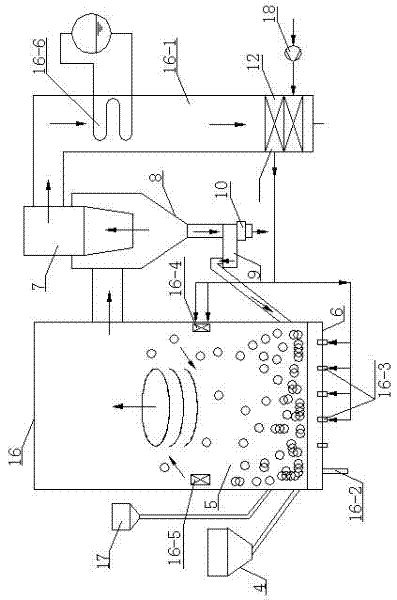

[0029] Embodiment 1: as Figures 1 to 4 As shown, this embodiment consists of a sludge granulator 1, a sludge dryer 2, a feeder 3, an air distribution plate 6, a cyclone separator 7, a small ash hopper 8, a return device 9, an ash discharge device 10, It consists of induced draft fan 11, air preheater 12, bag filter 13, chimney 14, circulating fluidized bed boiler 16, air intake pump 18, superheater 16-6, and downstream flue 16-1.

[0030] The discharge port of the sludge granulator 1 is opposite to the feed port 2-1 of the sludge dryer 2, and the discharge box 2-4 of the sludge dryer 2 is connected to the fuel feed port 4 of the circulating fluidized bed boiler 16 In contrast, the cyclone separator 7 is connected to the circulating fluidized bed boiler 16 through pipelines. A small ash hopper 8 , a material return device 9 , and an ash discharge device 10 are arranged below the cyclone separator 7 , and the material return device 9 is connected to a circulating fluidized bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com